Manganese oxide nanotube loading type denitration catalyst and preparation method therefor

A denitration catalyst and nanotube technology, which is applied in the field of air pollution control, can solve the problems of denitration catalyst resistance to multiple poisons and less research on poisoning at the same time, and achieve excellent resistance to alkali/alkaline earth metals, good water resistance and sulfur resistance, and low sulfur dioxide. The effect of oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

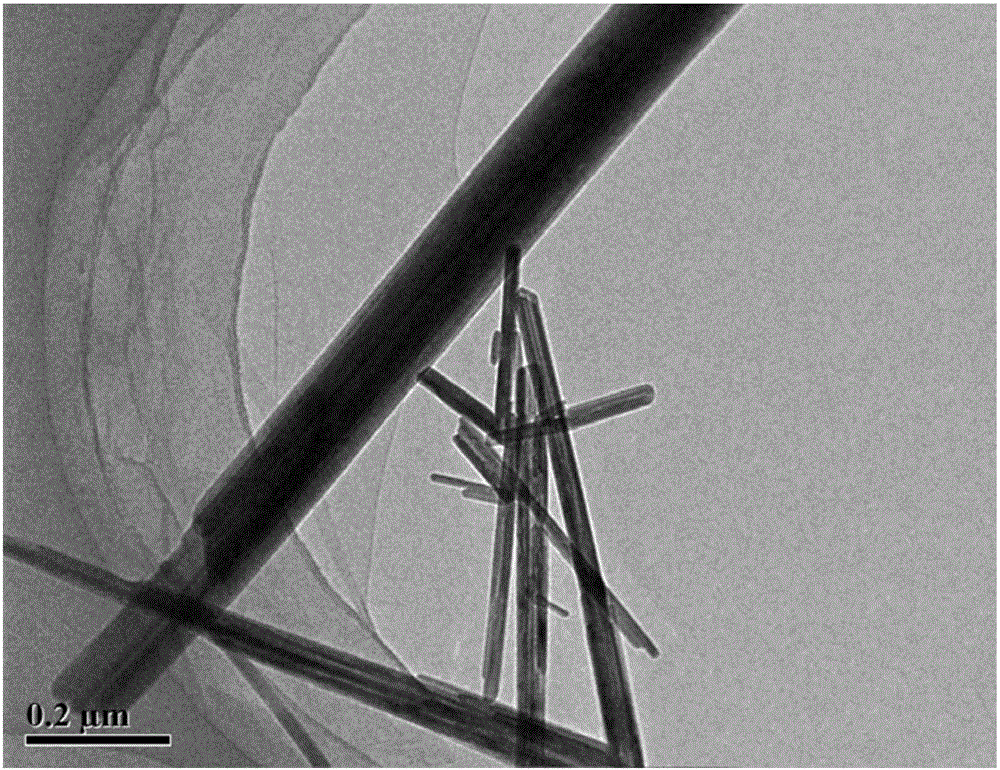

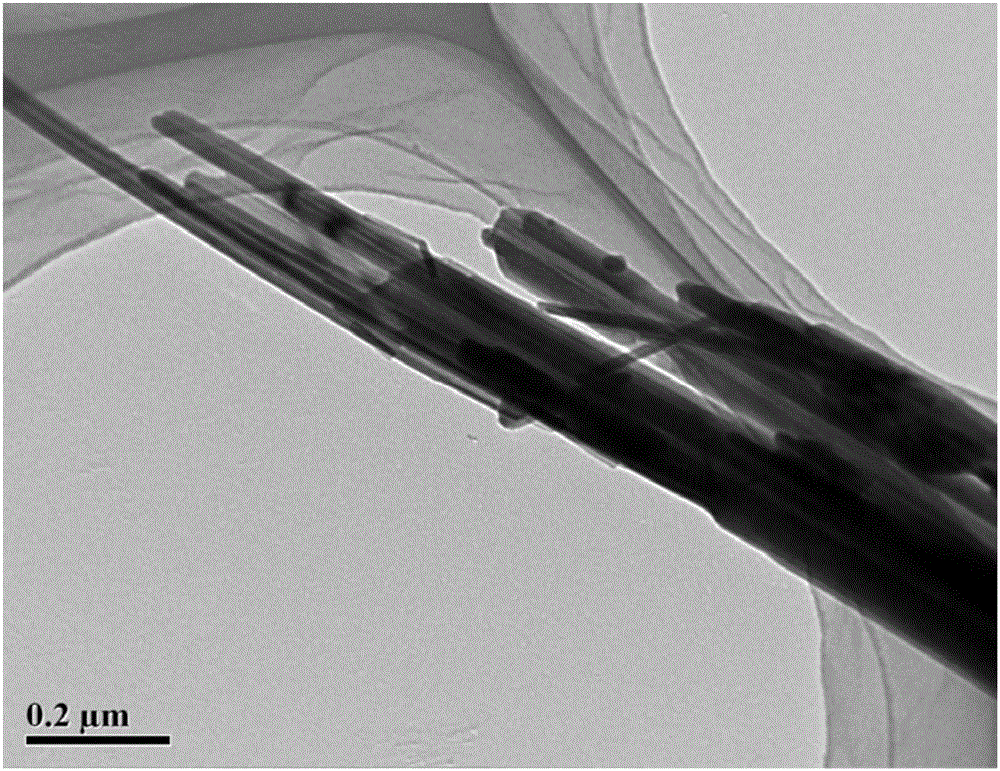

[0043]Preparation of manganese oxide nanotubes: The molar ratio of raw materials is potassium permanganate: dilute hydrochloric acid: water = 1:5:80. Add potassium permanganate and dilute hydrochloric acid into deionized water together, stir and dissolve for 1 hour to form a precursor solution; then pour it into a PTFE-lined hydrothermal kettle and heat it at 150°C for 24 hours, the filling degree of the hydrothermal kettle is 70%; the precipitate obtained by hydrothermal washing is washed with deionized water several times to a pH value ≥ 5, then it is filtered, and dried at 60°C, the microscopic morphology of the obtained manganese oxide titanium nanotubes is as follows figure 1 shown.

[0044] Catalyst preparation: Add 1 g of cerium nitrate hexahydrate and 2 g of ammonium tungstate to 100 ml of deionized water, stir and dissolve for 1 hour, add 4 g of manganese oxide nanotubes into it and continue stirring for 6 hours, then dry at 60 ° C, 450 ℃ burning for 3 hours to obtai...

Embodiment 2

[0048] Preparation of manganese oxide nanotubes: The molar ratio of raw materials is potassium manganate:dilute nitric acid:water=1:10:120. Add potassium permanganate and dilute hydrochloric acid into deionized water together, stir and dissolve for 2 hours to form a precursor solution; then pour it into a PTFE-lined hydrothermal kettle and heat it at 180°C for 24 hours, the filling degree of the hydrothermal kettle was 60%; the precipitate obtained by hydrothermal treatment was washed with deionized water several times until the pH value was ≥ 5, then it was filtered and dried at 80°C.

[0049] Catalyst preparation: Add 1 gram of vanadyl sulfate pentahydrate and 2 grams of ammonium molybdate into 100ml of deionized water, stir and dissolve for 1 hour, add 4g of manganese oxide nanotubes into it and continue stirring for 6 hours, then dry at 80°C. Burn at 500°C for 3 hours to obtain the finished catalyst.

[0050] Catalyst denitrification performance test: Put the finished cat...

Embodiment 3

[0053] Preparation of manganese oxide nanotubes: The molar ratio of raw materials is manganese acetate: acetic acid: water = 1:8:100. Add manganese acetate and acetic acid into deionized water together, stir and dissolve for 2 hours to form a precursor solution; then pour it into a PTFE-lined hydrothermal kettle and heat it at 130°C for 24 hours, and the filling degree of the hydrothermal kettle is 70% ; The precipitate obtained by hydrothermal treatment was washed with deionized water several times to a pH value ≥ 5, then filtered, and dried at 60°C.

[0054] Catalyst preparation: Add 1 g of niobium oxalate and 2 g of ammonium molybdate into 100 ml of deionized water, stir and dissolve for 1 hour, add 4 g of manganese oxide nanotubes into it and continue stirring for 6 hours, then dry at 60°C and burn at 400°C The finished catalyst was obtained in 3 hours.

[0055] Catalyst denitrification performance test: Put the finished catalyst prepared above into a fixed-bed quartz rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com