High-performance vanadium, cerium and titanium composite oxide catalyst for flue gas denitration and preparation method thereof

A composite oxide and catalyst technology, which is applied in the direction of physical/chemical process catalysts, heterogeneous catalyst chemical elements, chemical instruments and methods, etc., can solve the problems of poor mechanical strength and small specific surface area, and achieve good thermal stability, The effects of high denitrification performance, excellent denitrification activity and water and sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1. Preparation of cerium-titanium solid solution carrier

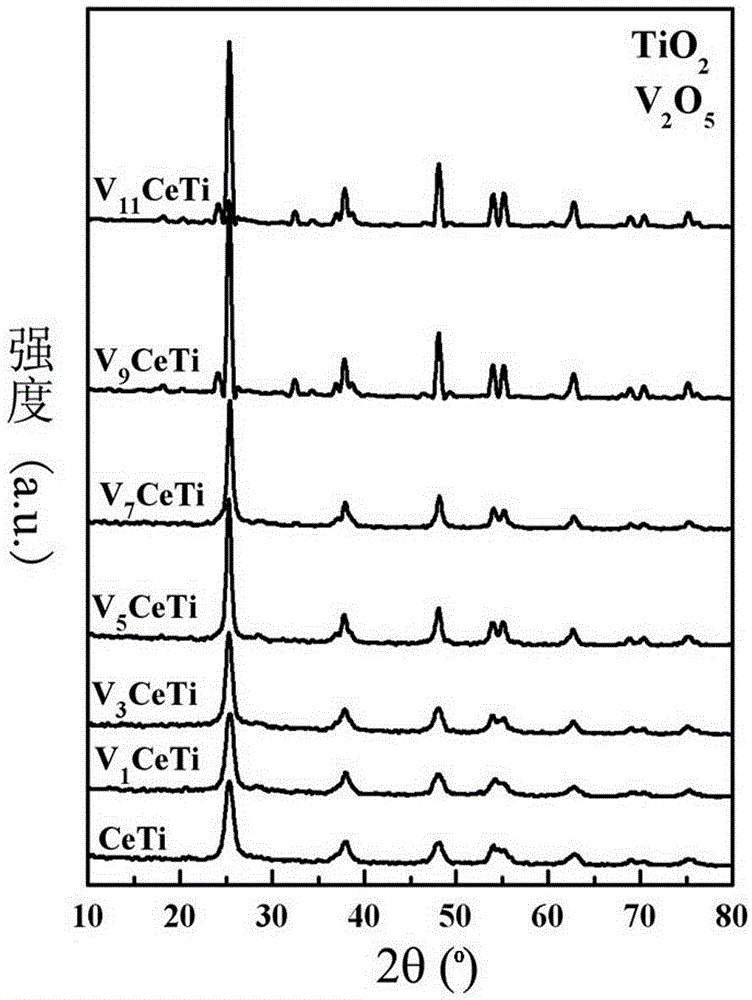

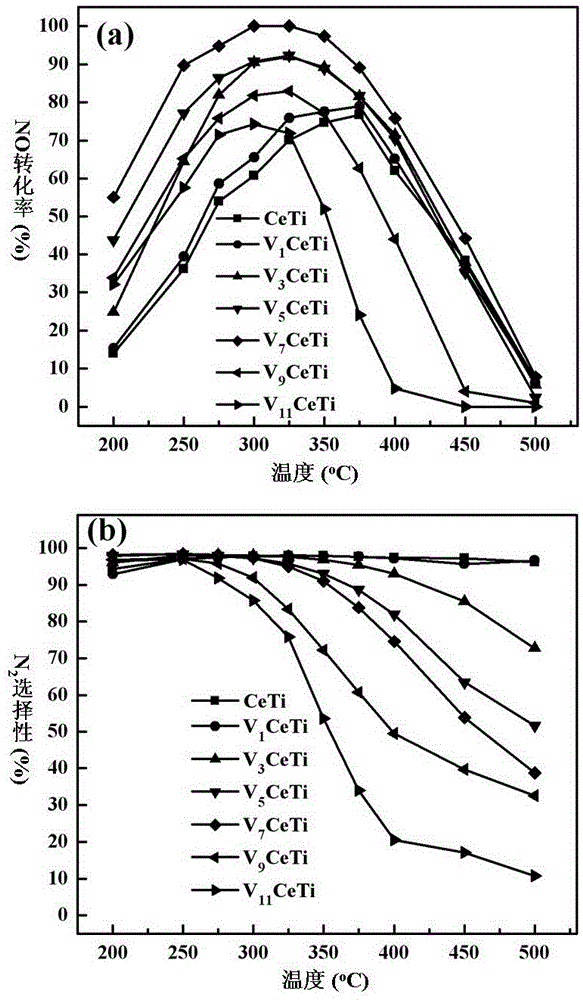

[0023] Disperse 20mL of tetra-n-butyl titanate and 0.62g of cerium nitrate in 20mL of absolute ethanol, add 18.08g of urea, and after magnetically stirring for 30min, transfer the mixed solution to a polytetrafluoroethylene-lined high-pressure reactor. o C water heating for 10h, then the reaction kettle was cooled to room temperature, and the sample was centrifugally washed, 110 o C drying 12h, grinding, 550 under air atmosphere in a tube furnace o C is calcined for 6 hours to obtain a cerium-titanium solid solution carrier, which is marked as CeTi. Its specific surface area test results are shown in Table 1, and its XRD measurement results are shown in Table 1. figure 1 , the denitrification performance test results are shown in figure 2 .

[0024]

Embodiment 2

[0025] Example 2.V 1 Preparation of CeTi catalyst

[0026] Mix 1g of CeTi with 10mL of ultrapure water, stir for 30min, add 1.11mL of 0.1mol·L -1 Ammonium metavanadate solution, continue to stir for 30min, at 90 o Stir and evaporate to dryness in a C oil bath; put the sample at 120 o C drying 12h, grinding, 500 under air atmosphere in a tube furnace o C was calcined for 5h, and the obtained vanadium-cerium-titanium composite oxide catalyst was marked as V 1 CeTi. Its specific surface area test results are shown in Table 1, and its XRD measurement results are shown in Table 1. figure 1 , the denitrification performance test results are shown in figure 2 .

Embodiment 3

[0027] Example 3.V 3 Preparation of CeTi catalyst

[0028] Mix 1 g of CeTi with 10 mL of ultrapure water, stir for 30 min, add 3.40 mL of 0.1 mol L -1 Ammonium metavanadate solution, continue to stir for 30min, at 90 o Stir and evaporate to dryness in a C oil bath; put the sample at 120 o C drying 12h, grinding, 500 under air atmosphere in a tube furnace o C was calcined for 5h, and the obtained vanadium-cerium-titanium composite oxide catalyst was marked as V 3 CeTi. Its specific surface area test results are shown in Table 1, and its XRD measurement results are shown in Table 1. figure 1 , the denitrification performance test results are shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com