Fume oxidation denitration catalyst prepared by sol-gel method and preparation process thereof

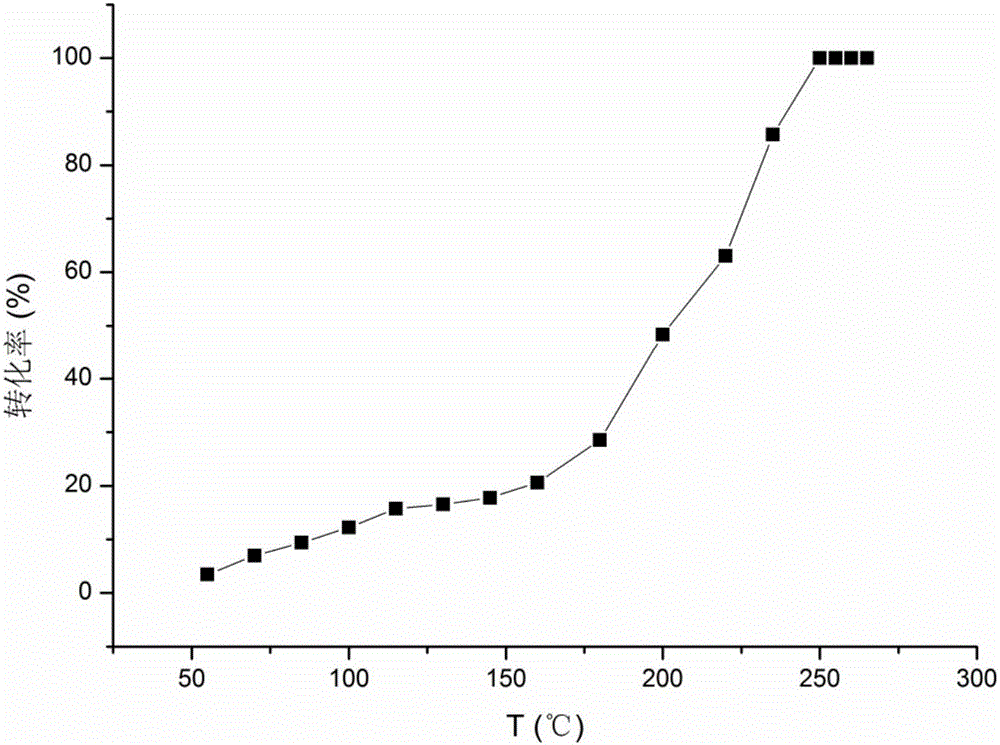

A technology of sol-gel method and denitration catalyst, which is applied in the field of flue gas oxidation denitration catalyst and its preparation, can solve the problems of poor denitration efficiency and high temperature, achieve good nitrogen oxide removal rate, low cost and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A flue gas oxidation denitrification catalyst prepared by a sol-gel method, comprising the following components, by weight percentage: manganese oxides account for 24.52 wt%, zirconium oxides account for 20.29 wt%, and cerium oxides account for 41.65 wt% .

[0041] The preparation steps are as follows:

[0042] (1) 11.41g manganese acetate, 8.40g zirconium nitrate, 16.70g cerium nitrate were dissolved in 100ml deionized water to obtain metal salt solution;

[0043] (2) 4.80g polyethylene glycol (PEG400) and 48.03g citric acid are dissolved in 150ml deionized water, stirred to obtain a mixed solution;

[0044] (3) adding the metal salt solution in step (1) dropwise to the mixed solution in step (2), and stirring to obtain a reaction solution;

[0045] (4) Stir the reaction solution in an oil bath at 80°C until the sol forms a gel;

[0046] (5) Aging the gel obtained in step (4) at room temperature for 16 hours; drying at 65° C. for 14 hours; and roasting at 450° C. fo...

Embodiment 2

[0049] A flue gas oxidation denitrification catalyst prepared by a sol-gel method, comprising the following components, by weight percentage: manganese oxides account for 27.19wt%, zinc oxides account for 16.16wt%, cerium oxides account for 46.13wt% .

[0050] The preparation steps are as follows:

[0051] (1) 15.41g manganese acetate, 7.40g zinc nitrate, 14.70g cerium nitrate are dissolved in 100ml deionized water to obtain metal salt solution;

[0052] (2) 6.80g polyethylene glycol (PEG2000) and 40.03g citric acid were dissolved in 150ml deionized water, and stirred to obtain a mixed solution;

[0053] (3) adding the metal salt solution in step (1) dropwise to the mixed solution in step (2), and stirring to obtain a reaction solution;

[0054](4) Stir the reaction solution in an oil bath at 85°C until the sol forms a gel;

[0055] (5) Aging the gel obtained in step (4) at room temperature for 12 hours; drying at 65° C. for 14 hours; and roasting at 500° C. for 6 hours to ...

Embodiment 3

[0058] A flue gas oxidation denitrification catalyst prepared by a sol-gel method, comprising the following components, by weight percentage: manganese oxides account for 19.52 wt%, tin oxides account for 21.05 wt%, and cerium oxides account for 33.10 wt% .

[0059] The preparation steps are as follows:

[0060] (1) 18.41g manganese acetate, 6.40g tin nitrate, 12.70g cerium nitrate are dissolved in 100ml deionized water to obtain metal salt solution;

[0061] (2) 4.80g polyethylene glycol (PEG6000) and 48.03g citric acid were dissolved in 150ml deionized water, and stirred to obtain a mixed solution;

[0062] (3) adding the metal salt solution in step (1) dropwise to the mixed solution in step (2), and stirring to obtain a reaction solution;

[0063] (4) Stir the reaction solution in an oil bath at 70°C until the sol forms a gel;

[0064] (5) Aging the gel obtained in step (4) at room temperature for 16 hours; drying at 75° C. for 18 hours; and roasting at 500° C. for 4 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com