Low-concentration methane catalytic combustion catalyst and preparation method of the same

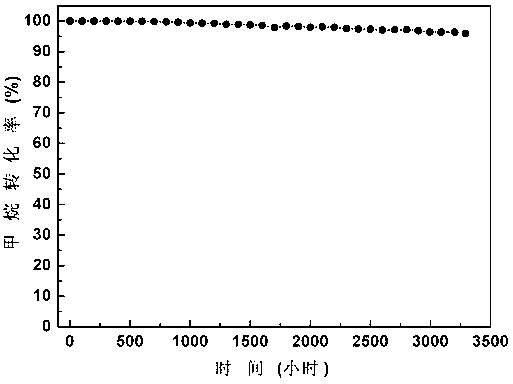

A methane catalytic combustion and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Poor stability, improved dispersion and stability, and improved low-temperature ignition starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Catalyst A: 0.47%Pd / 6.2%MgO / Al 2 O 3

[0027] (1) Weigh 16.10g MgCl 2 ·6H 2 O, add deionized water to dissolve to 20mL;

[0028] (2) Add 38g Al 2 o 3 The particles are immersed in the aqueous solution prepared in step (1), dried at 120°C for 10 hours, and calcined at 900°C for 3 hours to obtain the catalyst precursor;

[0029] (3) Immerse the catalyst precursor prepared in step (2) into 20 mL of Pd(NO3) containing 9.6 mg / mL Pd 2 solution, dried at 120°C for 10 hours, and calcined at 200°C for 2 hours to obtain the desired oxidized noble metal catalyst;

[0030] (4) The catalyst prepared in step (3) was washed with 10% H 2 -90%N 2 The mixed gas is reduced at 400°C for 3 hours to obtain a noble metal single-state catalyst, and the components of the catalyst are 0.47%Pd / 6.2%MgO / Al 2 o 3 .

Embodiment 2

[0031] Embodiment 2: Catalyst B: 0.96%Pd / 8.9%La 2 O 3 / Al 2 O 3

[0032] (1) Weigh 7.50g La(NO 3 ) 3 ·6H 2 O, add deionized water to dissolve to 25mL;

[0033] (2) 48g Al 2 o 3 The particles are immersed in the aqueous solution prepared in step (1), dried at 105°C for 15 hours, and calcined at 1000°C for 3 hours to obtain the catalyst precursor;

[0034] (3) Immerse the catalyst precursor prepared in step (2) into 26.4 mL of Pd(NO 3 ) 2 solution, dried at 105°C for 15 hours, and calcined at 250°C for 3 hours to obtain the desired oxidized noble metal catalyst;

[0035] (4) The catalyst prepared in step (3) was mixed with 20% H 2 -80%N 2 The mixed gas is reduced at 420°C for 2.5 hours to obtain a noble metal single-state catalyst, and the components of the catalyst are 0.96%Pd / 8.9%La 2 o 3 / Al 2 o 3 .

Embodiment 3

[0036] Embodiment 3: Catalyst C: 0.39%Pd / 9.6%CoO / Al 2 O 3

[0037] (1) Weigh 11.89g Co(NO 3 ) 3 ·6H 2 O, add deionized water to dissolve to 15mL;

[0038] (2) 28.8g Al 2 o 3 The particles are immersed in the aqueous solution prepared in step (1), dried at 110°C for 30 hours, and calcined at 1000°C for 3 hours to obtain the catalyst precursor;

[0039] (3) Immerse the catalyst precursor prepared in step (2) into 15.9 mL of PdCl containing 7.8 mg / mL Pd 2 solution, dried at 110°C for 30 hours, and after calcination at 210°C for 2 hours, washed the Cl in the catalyst with deionized water - , and then dried at 110°C for 30 hours to obtain the desired oxidized noble metal catalyst;

[0040] (4) The catalyst prepared in step (3) was washed with 10% H 2 -90%N 2 The mixed gas is reduced at 400°C for 3 hours to obtain a noble metal single-state catalyst, and the components of the catalyst are 0.39%Pd / 9.6%CoO / Al 2 o 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com