Catalyst for production of C2H4 through CO2 oxidized C2H6 dehydrogenation and preparation method of catalyst

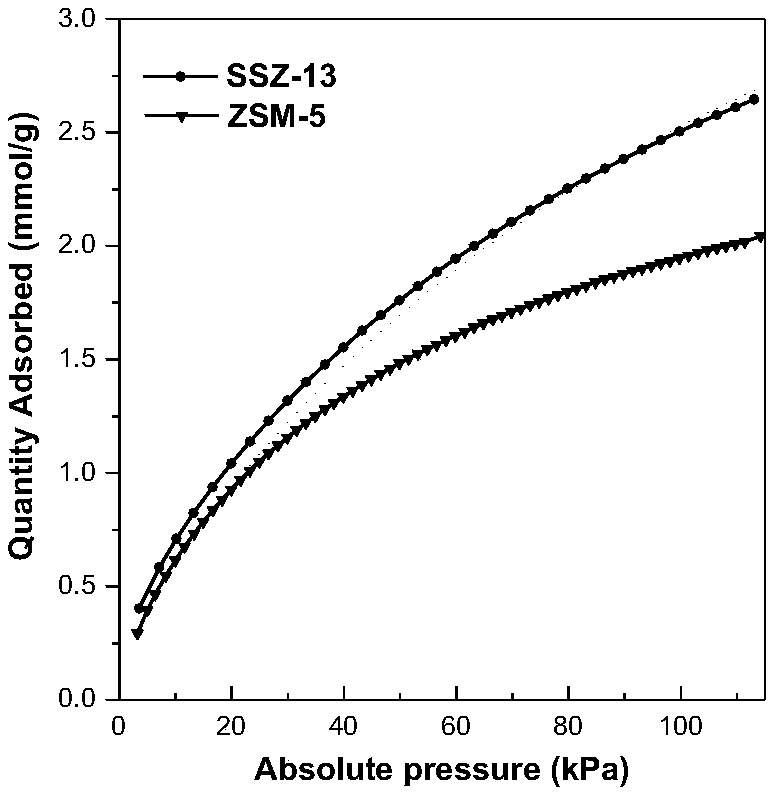

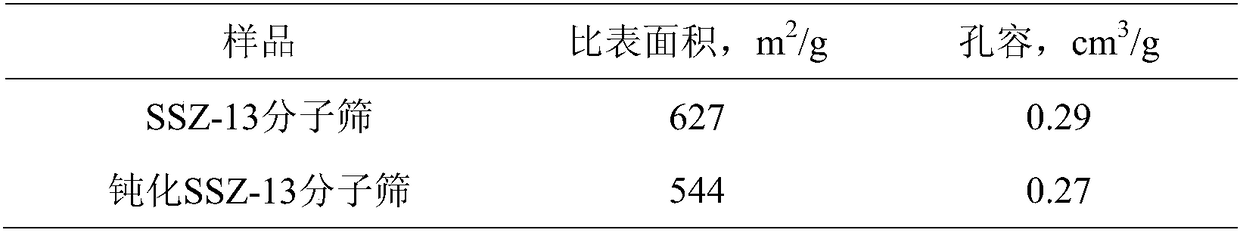

A carbon dioxide and ethane oxidation technology, applied in carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve problems such as weak carbon dioxide adsorption capacity and poor hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 0.93g of Cr(NO 3 ) 3 9H 2 O was dissolved in 24g of deionized water, and after stirring evenly, 10g of SSZ-13 microporous molecular sieve carrier was added, and then soaked in a constant temperature water bath at 80°C for 2h, and then the obtained mixture was centrifuged, and the separated solid was dried at 110°C for 10h, and then 540 ℃ calcination for 3 hours to obtain CO 2 Oxygen C 2 h 6 Dehydrogenation to C 2 h 4 The catalyst, the mass fraction of chromium in the catalyst is 0.3%, denoted as Cr 0.3 / SSZ-13.

Embodiment 2

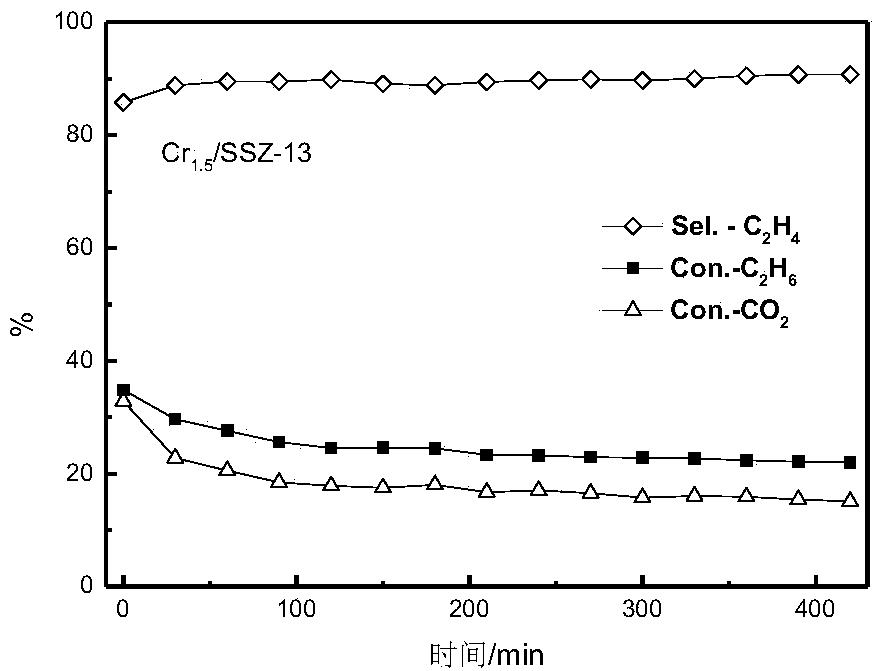

[0027] 1.56g, 2.21g and 4.94g of Cr(NO 3 ) 3 9H 2 O was dissolved in 24g of deionized water to prepare solutions with different Cr content. After stirring evenly, 10g of SSZ-13 microporous molecular sieve carrier was added, and then soaked in a constant temperature water bath at 80°C for 2h, and then the obtained mixture was centrifuged to separate the obtained The solid was dried at 110°C for 10h, and then calcined at 540°C for 3h to obtain CO 2 Oxygen C 2 h 6 Dehydrogenation to C 2 h 4 The catalyst, the mass fraction of chromium element in the catalyst is 0.5%, 0.7% and 1.5%, respectively denoted as Cr 0.5 / SSZ-13,Cr 0.7 / SSZ-13 and Cr 1.5 / SSZ-13.

Embodiment 3

[0029] 62.18g of Cr(NO 3 ) 3 9H 2 O was dissolved in 24g of deionized water, and after stirring evenly, 10g of SSZ-13 microporous molecular sieve carrier was added, and then soaked in a constant temperature water bath at 80°C for 2h, and then the obtained mixture was centrifuged, and the separated solid was dried at 110°C for 10h, and then 540 ℃ calcination for 3 hours to obtain CO 2 Oxygen C 2 h 6 Dehydrogenation to C 2 h 4 The catalyst, the mass fraction of chromium in the catalyst is 10%, denoted as Cr 10 / SSZ-13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com