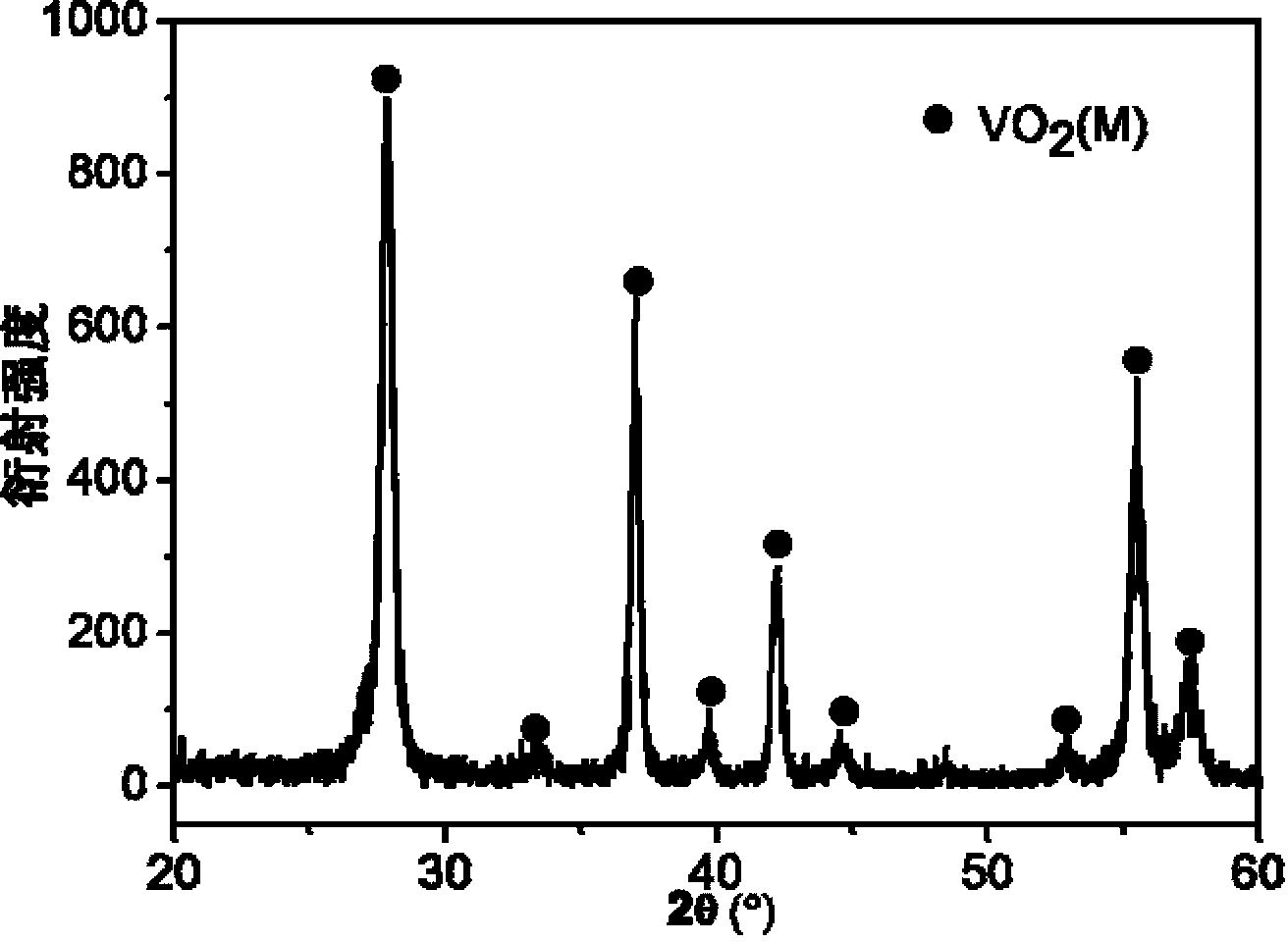

Method for preparing vanadium dioxide powder through hydrothermal auxiliary homogeneous precipitation method

A uniform precipitation method, vanadium dioxide technology, applied in vanadium oxide, nanotechnology and other directions, to achieve the effects of simple and controllable operation, sufficient reaction, and easy control of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a preparation method of vanadium dioxide powder, comprising the following steps: preparing an aqueous solution of tetravalent vanadium ions; adding a uniform precipitant of specified quality into the obtained aqueous solution, stirring until uniform; and then transferring the obtained mixed solution to Put it into a hydrothermal kettle, heat it up, keep it warm, and synthesize it through hydrothermal reaction; the product after natural cooling is centrifuged, washed, and dried to obtain vanadium dioxide powder. More specifically, as an example, the method of the present invention may include the following steps.

[0040] (1) Prepare an aqueous solution containing tetravalent vanadium ions

[0041] The preparation of the aqueous solution containing tetravalent vanadium ions can be prepared by a method commonly used in this field: dissolving the tetravalent soluble vanadium raw material in an appropriate amount of water, preferably deionized water, ...

Embodiment 1

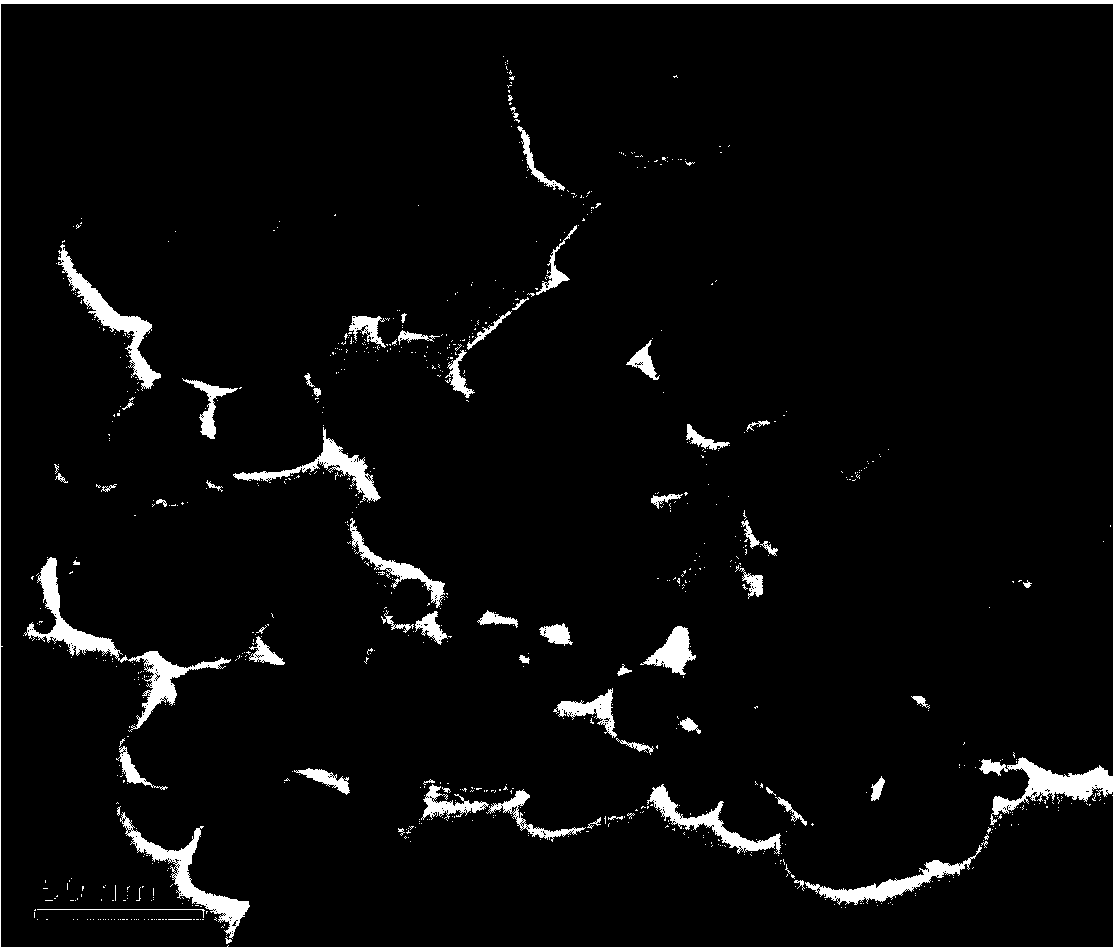

[0058] Prepare 0.4mol / L VOSO 4 50ml of aqueous solution, add 2.5g of urea and magnetically stir at room temperature until a uniform blue solution is obtained, then put the mixed solution into a 100ml hydrothermal kettle, conduct a hydrothermal reaction at 180°C for 24 hours, cool naturally to room temperature, and centrifuge and dry to obtain Powder, the product is a flake structure, and its main crystal phase is B phase.

Embodiment 2

[0060] Prepare 0.4mol / L VOSO 4 50ml of aqueous solution, add 2.5g of urea and magnetically stir at room temperature until a uniform blue solution is obtained, then put the mixed solution into a 100ml hydrothermal kettle, conduct a hydrothermal reaction at 220°C for 24 hours, cool naturally to room temperature, and centrifugally dry to obtain Powder, the product is a mixture of flakes and granules, and its main crystal phases are phase A and phase B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com