Preparation method of high temperature resistant vanadium tungsten titanium oxide catalyst

An oxide, vanadium-tungsten-titanium technology, applied in the field of preparation of vanadium-tungsten-titanium oxide catalysts, can solve the problems of poor thermal stability at high temperature, narrow catalyst operating temperature window, uneven distribution of active components, etc., to achieve good water resistance Effects of sulfur and thermal stability, excellent N2 generation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

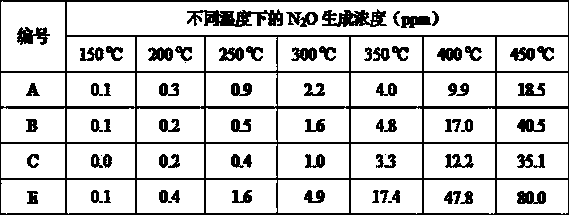

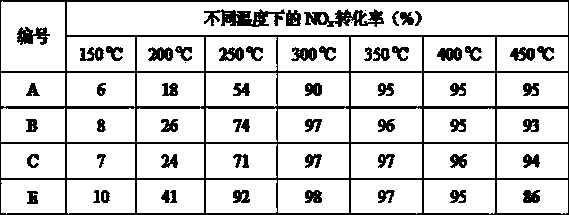

Embodiment 1

[0035] According to W / Ti molar ratio is 1.0, ammonium tungstate is dissolved in titanium sulfate solution, continuously stirs until ammonium tungstate dissolves completely, then adds excess precipitating agent urea in this solution, and in 90 o Under the condition of C, keep stirring for 12 h, then perform suction filtration and washing, and then put the obtained solid in an oven at 100-110 o C drying 12 h, muffle furnace at 500 o C roasting in air for 5 h to obtain a powdery solid, and then ammonium metavanadate and powdery solid according to V 2 o 5 Loading capacity is 1 wt%, add water, mix and stir for 1 h, rotate the mixture until the water volatilizes completely, put the obtained solid in an oven at 100-110 o C drying 12 h, muffle furnace at 500 o C was calcined in air for 5 h to obtain a powdered catalyst, called catalyst A.

Embodiment 2

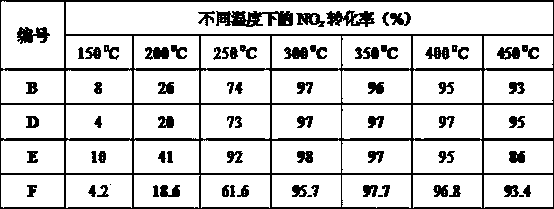

[0037] Other conditions were the same as in Example 1, and the W / Ti molar ratio was 2.0 to obtain catalyst B.

Embodiment 3

[0039] Other conditions were the same as in Example 1, and the W / Ti molar ratio was 3.0 to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com