High-strength and high-electroconductivity copper alloy pipe, bar, and wire rod

By adding Co, P and Sn to high-strength and high-conductivity copper alloys, and using hot extrusion and heat treatment processes to form fine precipitates, the problems of oxidation loss and adhesion of existing copper alloys during heat treatment are solved, and low-cost, Highly conductive and strong materials are produced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

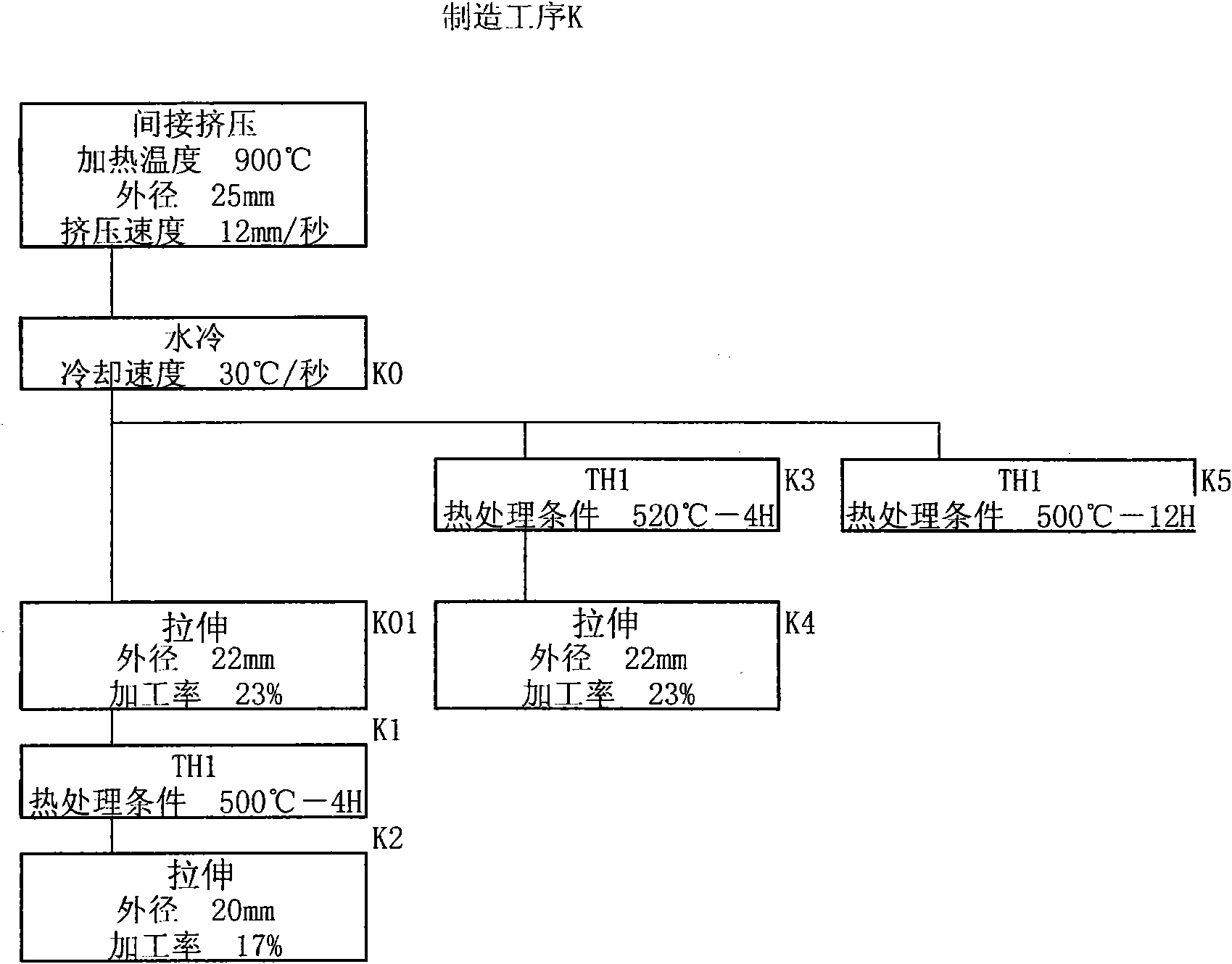

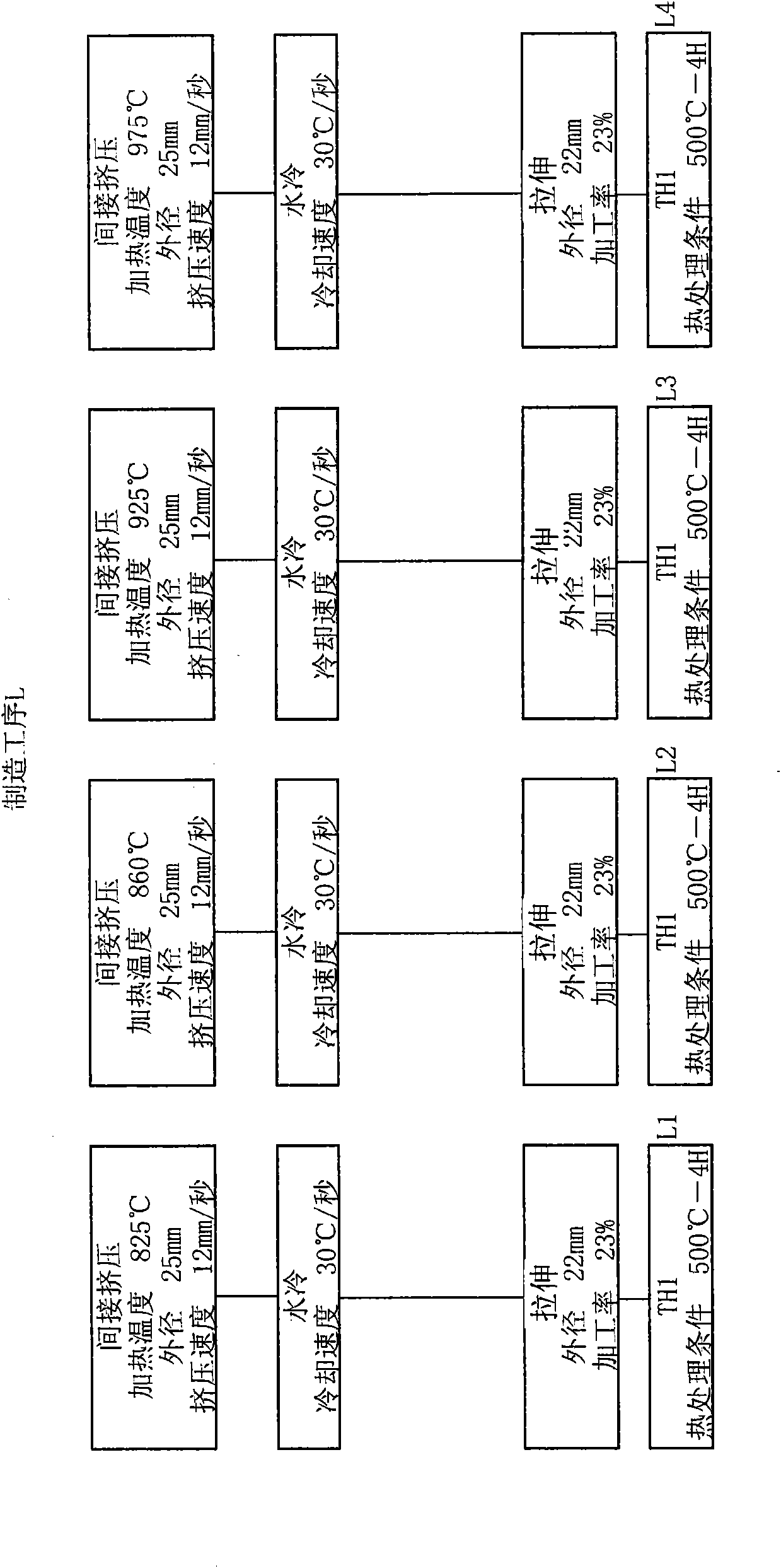

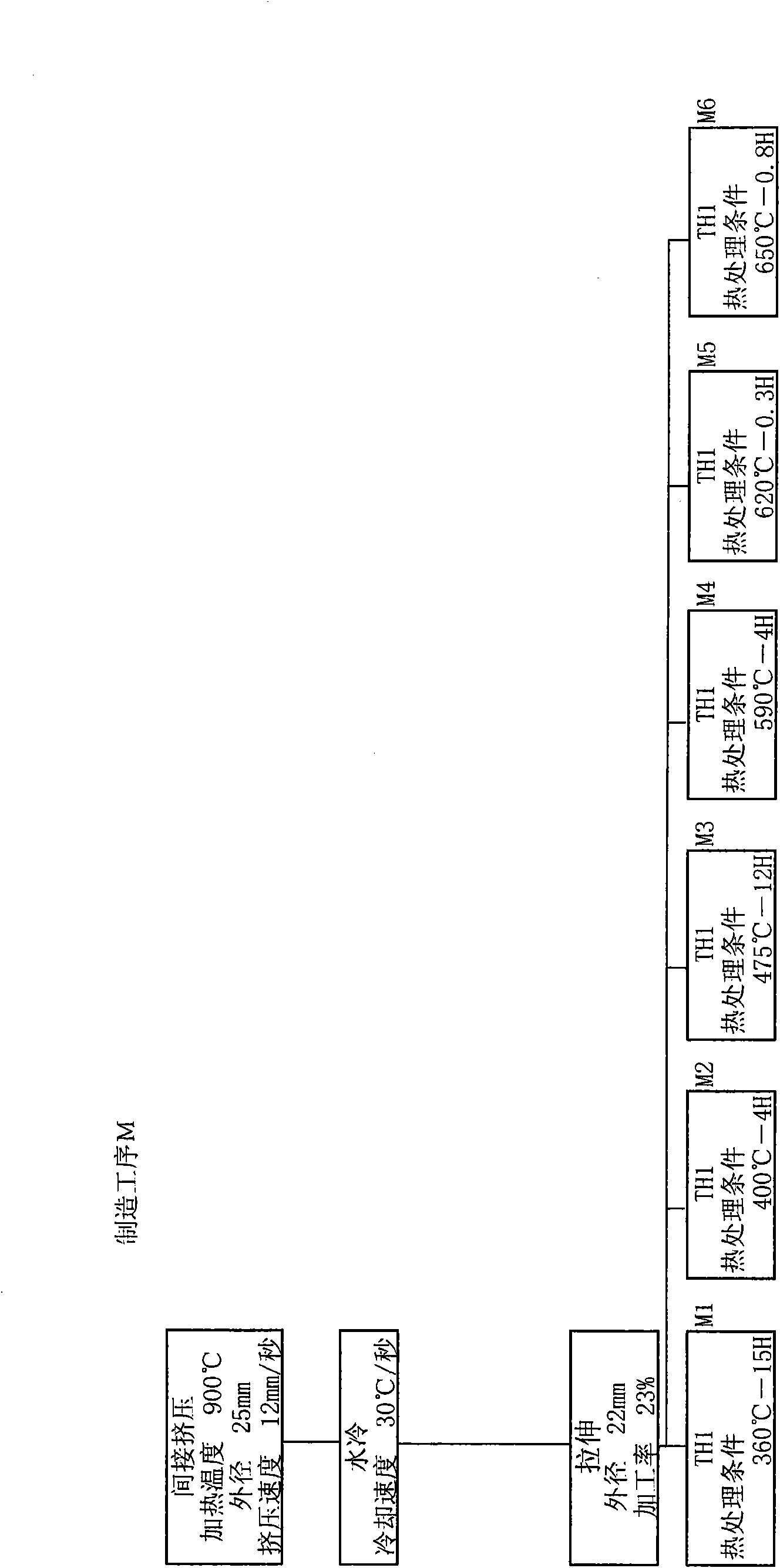

Method used

Image

Examples

Embodiment Construction

[0040] The high-performance copper pipe / rod / wire according to the embodiment of the present invention will be described. In this invention, the 1st invention alloy, the 2nd invention alloy, and the 3rd invention alloy of the alloy composition in the high-performance copper pipe / rod / wire concerning Claim 1 to Claim 4 are proposed. In this specification, when expressing an alloy composition, it is assumed that an element symbol enclosed in parentheses such as [Co] indicates the content value (mass%) of the element. In addition, the first to third invention alloys are collectively referred to as invention alloys.

[0041] The alloy composition of the first invention alloy is as follows: 0.13 to 0.33 mass% (preferably 0.15 to 0.32 mass%, more preferably 0.16 to 0.29 mass%) of Co, 0.044 to 0.097 mass% (preferably 0.048 to 0.094 mass%, more preferably 0.051 mass%) ~0.089mass%) of P, 0.005~0.80mass% (preferably 0.005~0.70mass%), do not need a particularly large strength, but when hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com