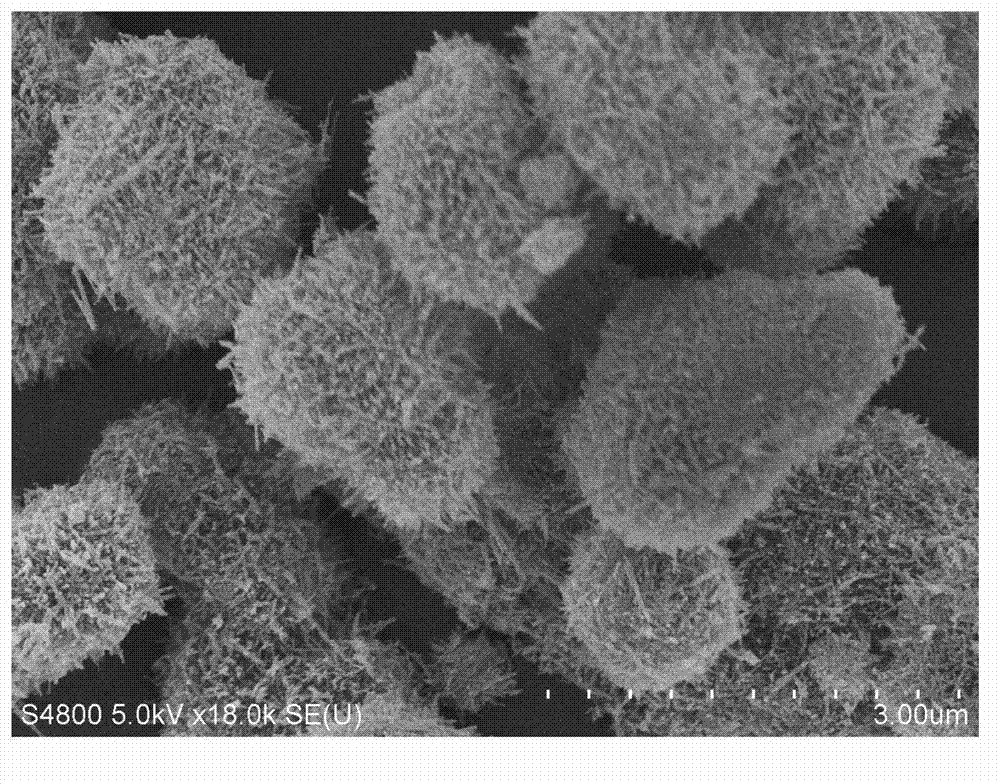

Preparation method of three-dimensional echinoid ZnS/CdS composite semiconductor photocatalytic nano material

A composite semiconductor and nanomaterial technology is applied in the field of preparation of three-dimensional sea urchin-like ZnS/CdS composite semiconductor photocatalytic nanomaterials, which can solve the problems of low photocatalytic efficiency of ZnS, and achieve good application prospects, high catalytic activity and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

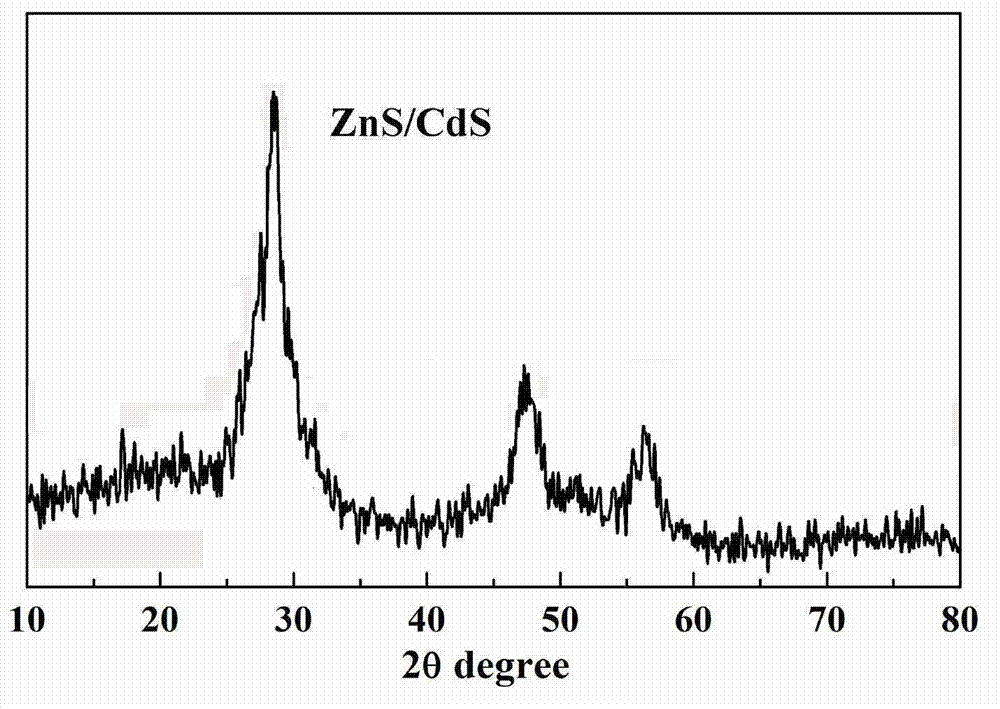

[0022] A method for preparing a three-dimensional sea urchin-shaped ZnS / CdS composite semiconductor photocatalytic nanomaterial, comprising the following steps:

[0023] 1) Preparation of sea urchin-like ZnS with uniform scale

[0024] Weigh 0.219gZn(CH 3 COO) 2 2H 2 O, dissolved in a 20mL polytetrafluoroethylene reactor filled with 12mL distilled water under magnetic stirring, then add 5mL of ethylenediamine, add 0.2mL carbon disulfide after stirring for 2-3min, and then add 0.5mmol after stirring the system evenly Cetyltrimethylammonium bromide, continue to stir until the cetyltrimethylammonium bromide is completely dissolved; put the above polytetrafluoroethylene reactor into a stainless steel reactor jacket, tighten the lid of the kettle, and store at 170°C After the reaction, the reaction system was naturally cooled to room temperature, centrifuged to obtain a white precipitate product, washed with ethanol and distilled water for 3 times, and then dried in a vacuum ove...

Embodiment 2

[0029] Change the carbon disulfide in step 1) in Example 1 to add 1.5 mmol thiourea, and the other schemes are the same.

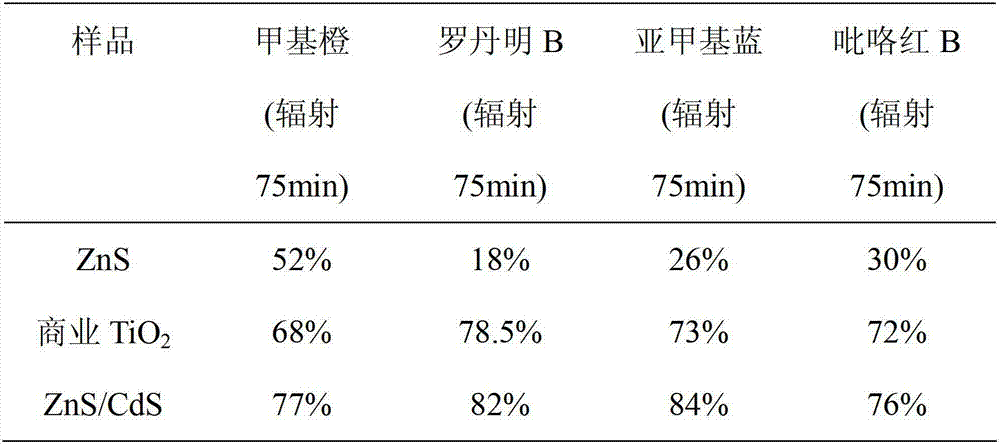

[0030] The obtained composite material was tested, and the results showed that the composite catalyst was selective for dyes, and only showed excellent photocatalytic activity for methyl orange, and the degradation rate reached 65%.

Embodiment 3

[0032] The surfactant in step 1) in Example 1 is changed to polyvinylpyrrolidone, and the other schemes are the same.

[0033]The dispersibility of the obtained sample was slightly inferior to that of Example 1, and the photocatalytic degradation rate of four organic dyes reached: 75% for methyl orange, 79.4% for rhodamine B, 82% for methylene blue, and 60.2% for pyrrored B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com