Method for applying gold hydroxyapatite loaded catalyst to catalytic oxidation reaction of formaldehyde at room temperature

A technology of gold hydroxyapatite and hydroxyapatite, which is applied in the field of supported gold hydroxyapatite catalysts, can solve the problems of complicated operation, difficult regeneration, and fast failure of composite technology, and achieves the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Dissolve 12.6g of calcium nitrate hydrate in a mixed solution with 60ml of water and 60ml of absolute ethanol, dissolve 4.2g of diamine hydrogen phosphate in 120ml of water to form solutions X and Y respectively, and gradually drop the Y solution at room temperature Add it to the X solution, and finally form a milky white precipitate, then adjust the pH value to 10 with ammonia water, and magnetically stir overnight in a water bath at 80°C. Medium roasting for 5h to finally obtain the HAP carrier;

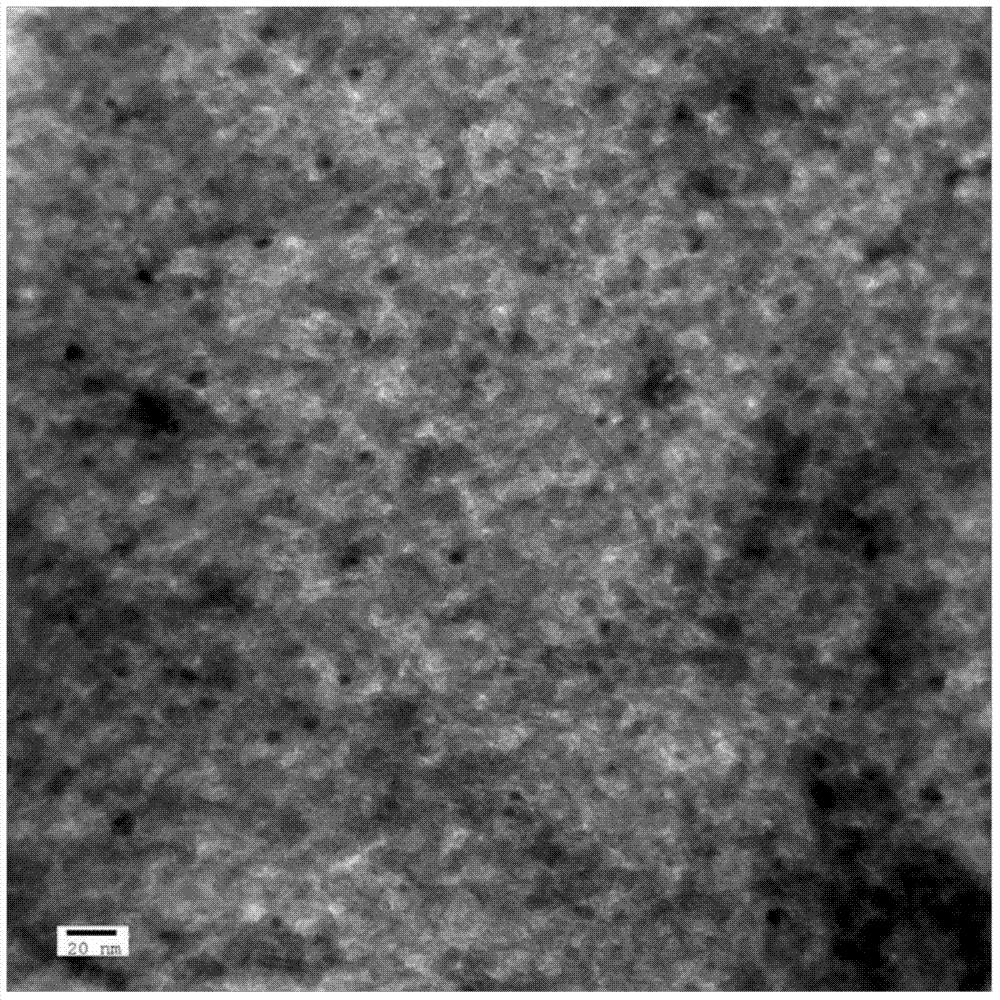

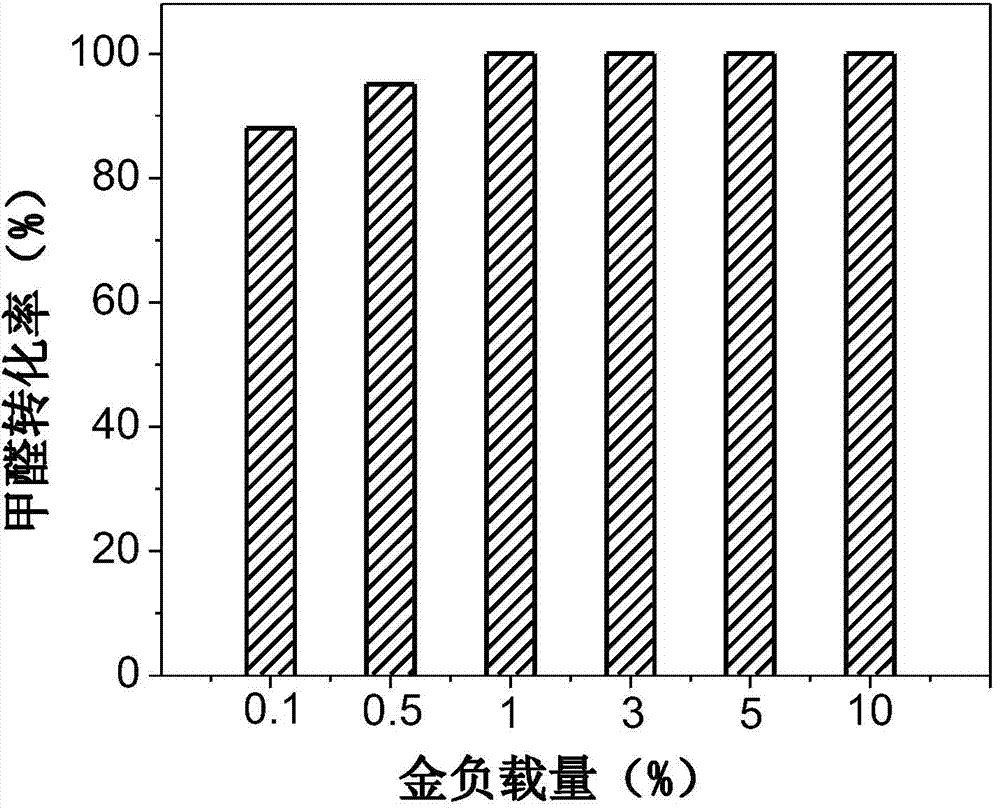

[0016] (2) Add 0.022g HAuCl 4 , 0.4g urea and 10g HAP were dissolved in 500ml of deionized water, stirred at 80°C for 8h in the dark, then aged for 12h at room temperature, washed by suction filtration (centrifugal separation) to remove Cl - ions, the obtained sample was dried at 80°C for 16h, and then calcined at 200°C for 4h to obtain a 0.1%Au / HAP catalyst.

[0017] (3) Catalytic oxidation to remove formaldehyde is carried out in a quartz tube fixed-bed reactor with ...

Embodiment 2

[0019] Process is identical with embodiment 1, difference is to take by weighing 0.11g HAuCl 4 0.5%Au / HAP catalyst was prepared with 2g urea, the reaction temperature was 20°C, and the initial concentration of formaldehyde was 100ppm. Under these conditions, the conversion rate of formaldehyde was 95%.

Embodiment 3

[0021] Process is identical with embodiment 1, difference is to take by weighing 0.22g HAuCl 4 1%Au / HAP catalyst was prepared with 4g urea, the reaction temperature was 10℃, and the initial concentration of formaldehyde was 300ppm. Under these conditions, the conversion rate of formaldehyde was 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com