M3C pre-charging method based on staggered grouping

A pre-charged, interleaved technology, applied in electrical components, output power conversion devices, and AC power input to DC power output, etc., can solve problems such as bridge arm energy imbalance, failure to reach predetermined values, capacitance voltage deviation, etc. , to achieve the effect of reducing the starting inrush current, reducing the inrush current, and reducing the amplitude difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific method described in the present invention will be described in more detail below in conjunction with the accompanying drawings of the present invention.

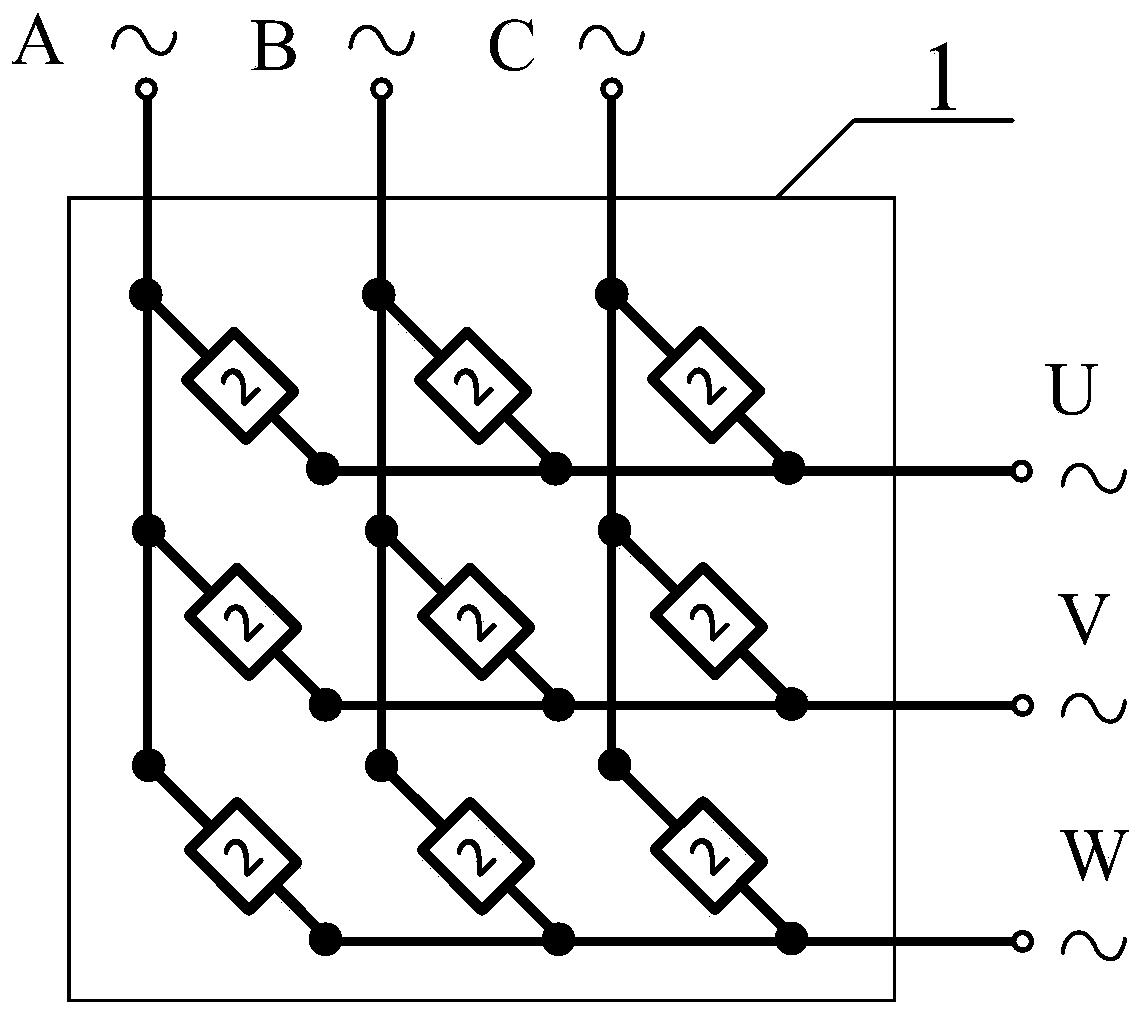

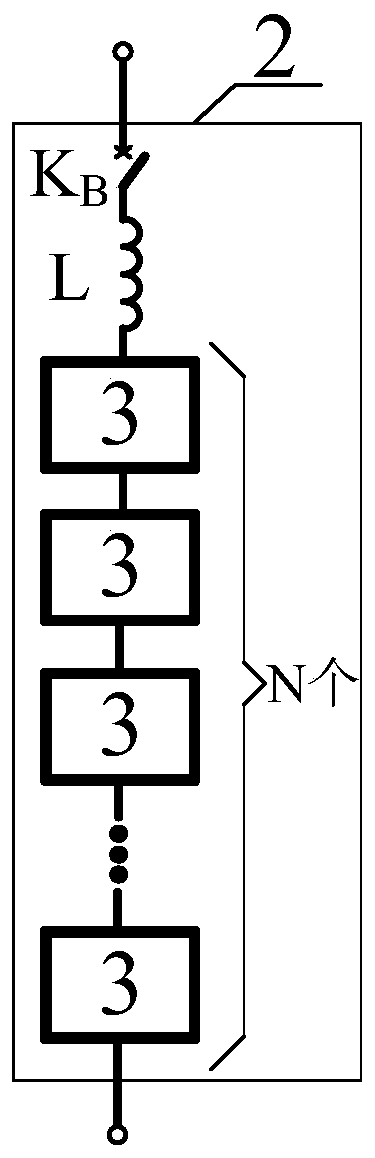

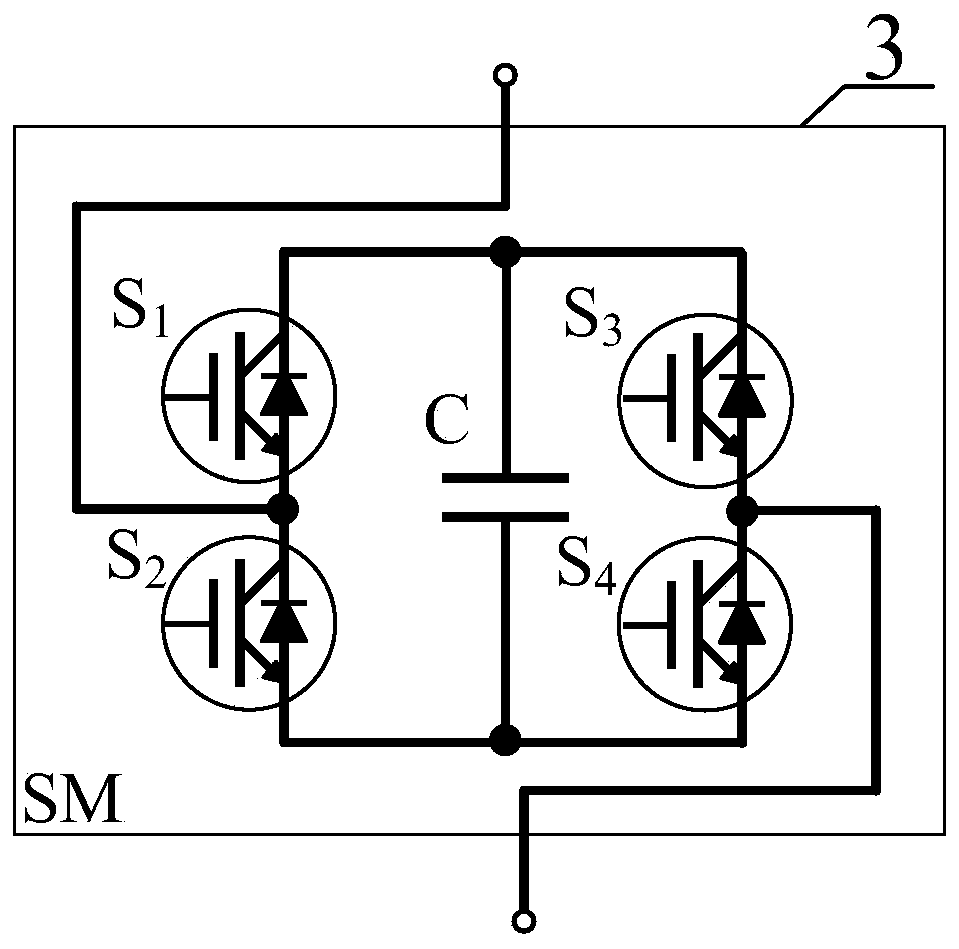

[0028] like figure 1 As shown, the modular multilevel matrix converter (M3C) system 1 specifically includes 9 bridge arms; each M3C bridge arm unit 2 includes N subunit modules, a bridge arm inductor L and a bridge arm short circuiter KB, like Figure 2a shown. Figure 2b The structure of the sub-module unit 3 is given, which specifically includes 4 power switch tubes IGBT (S1, S2, S3, S4) in an H-bridge structure, and a capacitor C.

[0029] image 3 A schematic diagram of the grouping of subunit modules on the bridge arm of the M3C system in the present invention is given, as image 3 As shown, it is an interleaved grouping: first, according to the input and output voltage conditions and the number of bridge arm sub-modules under normal operation, the minimum value of the capacitor voltage of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com