Method for preparing carbon loading Pd nanometer particle catalyst by using homogeneous precipitation-reduction in situ method

A nanoparticle, homogeneous precipitation technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of Pd nanoparticle agglomeration and poor catalyst particle dispersion question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] A method for preparing a carbon-supported Pd nanoparticle catalyst by homogeneous precipitation-in-situ reduction method, comprising the following steps:

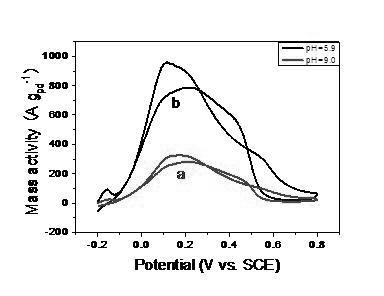

[0030] 1. Weigh 60 mg of Vulcan XC-72R activated carbon powder from Cabot Company, add 3.13 ml 0.045 mol / L PdCl 2 solution, then adjust the pH value of the solution to 5.6~7.4, stir at high speed (or ultrasonic vibration) for 0.5~48 hours to make the mixture uniform, and heat in a water bath at 30~100°C for 2 hours.

[0031] 2. At room temperature (25°C), slowly add excess reducing agent solution (NaBH 4 ), mechanically stirred for 1 hour to completely react the metal salt with the reducing agent.

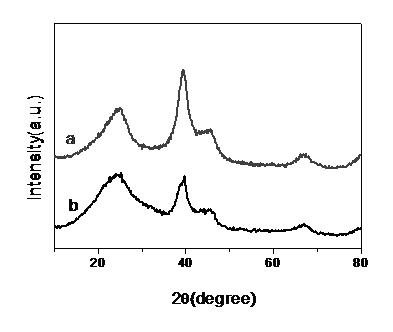

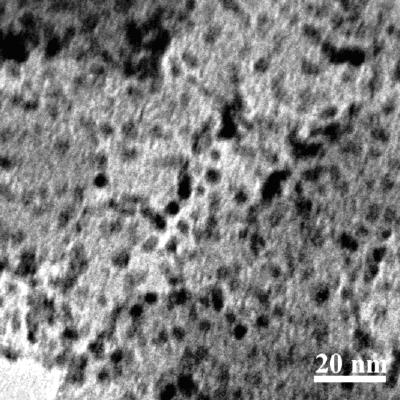

[0032] 3. After washing with water several times, check with silver nitrate solution until there is no chloride ion in the eluate. in N 2 Dry at 50°C under the same conditions to prepare a Pd / C catalyst with a metal loading of 20%, in which the particle size of the catalyst is about 2.0-4.0 nm.

[0033]

example 2

[0035] A method for preparing a carbon-supported Pd nanoparticle catalyst by homogeneous precipitation-in-situ reduction method, comprising the following steps:

[0036] 1. Weigh 60 mg of self-made carbon nanotubes (CNTs) with a tube diameter of 10-20nm, add 3.13 ml of 0.045 mol / L PdCl 2 , and then adjust the pH value of the solution to 5~7, and stir at high speed (or ultrasonic oscillation) for 0.5~48 hours to make the mixture uniform.

[0037]2. At room temperature (25°C), slowly add excess reducing agent solution (NaBH 4 ), mechanically stirred for 1 hour to completely react the metal salt with the reducing agent, and heated in a water bath at 30-100°C for 2 hours.

[0038] 3. After washing with water several times, check with silver nitrate solution until there is no chloride ion in the eluate. in N 2 The Pd / CNTs catalyst with a metal loading of 20% was obtained by drying at 50°C under atmospheric conditions, and the particle size of the catalyst was about 1.5-4.0nm.

...

example 3

[0041] A method for preparing a carbon-supported Pd nanoparticle catalyst by homogeneous precipitation-in-situ reduction method, comprising the following steps:

[0042] 1. Weigh 60 mg of carbon molecular sieve, add 3.13 ml 0.045 mol / L PdCl 2 solution, then adjust the pH value of the solution to 5~7, stir at high speed (or ultrasonic vibration) for 0.5~48 hours to make the mixture uniform, and heat in a water bath at 30~100°C for 2 hours.

[0043] 2. At room temperature (25°C), slowly add excess reducing agent solution (NaBH 4 ), mechanically stirred for 1 hour to completely react the metal salt with the reducing agent.

[0044] 3. After washing with water several times, check with silver nitrate solution until there is no chloride ion in the eluate. in N 2 Drying at 50°C under atmospheric conditions, the carbon molecular sieve-supported Pd nanoparticle catalyst with a metal loading of 20% was prepared, and the particle size of the catalyst was about 2.0-4.0 nm.

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com