Two-dimensional graphene-coated copper composite material with core-shell structure and preparation method and application thereof

A technology of graphene wrapping and composite materials, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems of reducing material catalysis and conductivity, unstable physical and chemical properties, etc., to ensure catalytic ability and conductivity , Avoid oxidation of copper particles, great simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Prepare graphene oxide (GO) dispersion liquid. Graphene oxide (GO) is an oxide of graphene, and its surface contains various oxygen-containing groups such as hydroxyl group and carboxyl group. Because these polar functional groups can interact with water molecules, GO has good dispersibility in water solvents, and a GO dispersion close to a solution can be obtained. Weigh 10 mg of GO into a reagent bottle containing 20 ml of deionized water, and ultrasonically disperse for 60 min to obtain a GO dispersion with a concentration of 0.5 mg / ml.

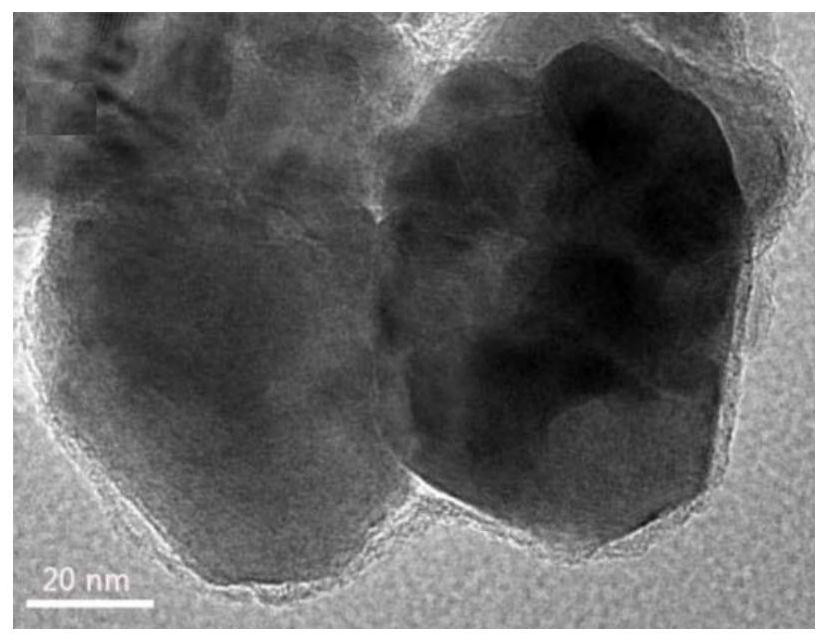

[0034] Step 2: First, 50 mg of the prepared pure copper powder was uniformly dispersed in 100 ml of deionized water by ultrasonic dispersion, and then 0.3 ml of 3-aminopropyltriethoxysilane (APTES) was added under magnetic stirring. After the temperature was raised to 60° C. and the stirring was continued for 4 hours, the obtained mixed suspension was sealed in a reaction kettle and kept at 100° C. for 24 hours. After the r...

Embodiment 2

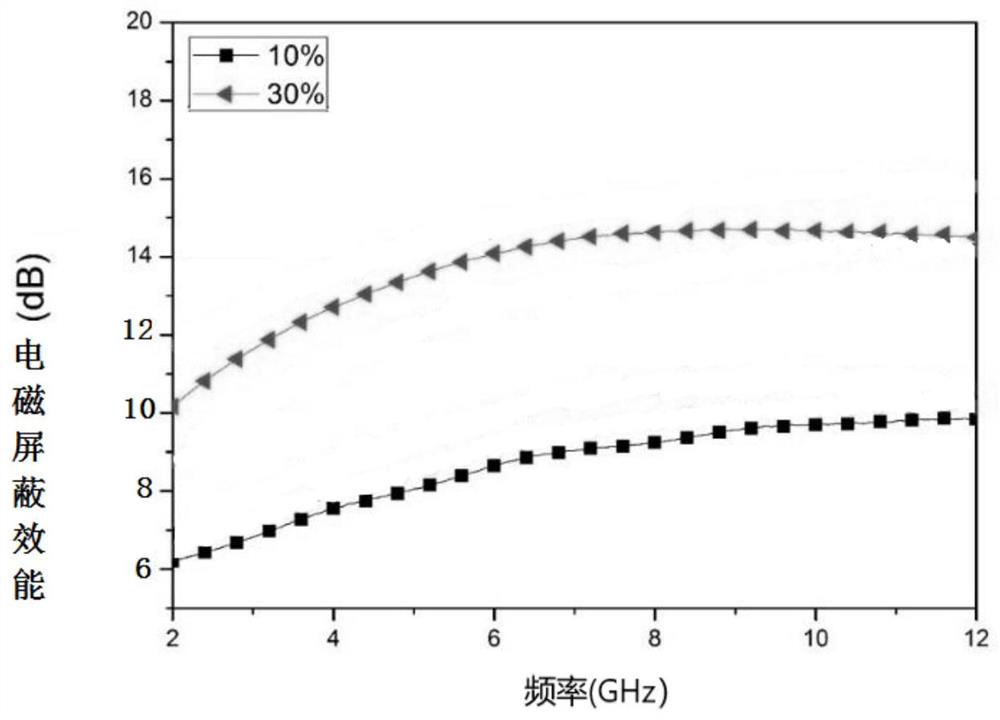

[0043] This example relates to a method for preparing polyethylene oxide / graphene-coated copper nanocomposites for electromagnetic shielding, the method comprising the following steps:

[0044] Step 1: Weigh 10 mg of GO into a reagent bottle containing 20 ml of deionized water, and ultrasonically disperse for 60 minutes to obtain a GO dispersion with a concentration of 0.5 mg / ml.

[0045]Step 2: First, 50 mg of the prepared pure copper powder was uniformly dispersed in 100 ml of deionized water by ultrasonic dispersion, and then 0.3 ml of 3-aminopropyltriethoxysilane (APTES) was added under magnetic stirring. After the temperature was raised to 60° C. and the stirring was continued for 4 hours, the obtained mixed suspension was sealed in a reaction kettle and kept at 100° C. for 24 hours. After the reactor was naturally cooled to normal temperature, the precipitate deposited on the bottom of the reactor was collected and washed repeatedly with deionized water. The surface-mod...

Embodiment 3

[0053] This example relates to a method for preparing polyethylene oxide / graphene-coated copper nanocomposites for electromagnetic shielding, the method comprising the following steps:

[0054] Step 1: Prepare graphene oxide (GO) dispersion liquid. Graphene oxide (GO) is the oxide of graphene, and its surface contains various oxygen-containing groups such as hydroxyl group and carboxyl group. Since these polar functional groups can interact with water molecules, GO has good dispersibility in water solvents, and a GO dispersion close to a solution can be obtained. Weigh 10 mg of GO into a reagent bottle containing 20 ml of deionized water, and ultrasonically disperse for 60 min to obtain a GO dispersion with a concentration of 0.5 mg / ml.

[0055] Step 2: First, 50 mg of the prepared pure copper powder was uniformly dispersed in 100 ml of deionized water by ultrasonic dispersion, and then 0.3 ml of 3-aminopropyltriethoxysilane (APTES) was added under magnetic stirring. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com