Synthesis method of 3,3,4,4-tetrafluoropyrrolidine

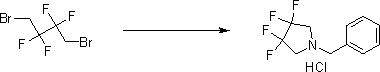

A technology of tetrafluoropyrrolidine and tetrafluoropyrrolidine hydrochloride, which is used in the synthesis of 3,3,4,4-tetrafluoropyrrolidine, and synthesizes 3,3,4,4-tetrafluoropyrrole from butanedione In the field of alkane, it can solve the problem of toxic yield of fluorine, and achieve the effect of clean reaction, simple operation and efficient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

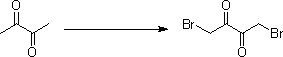

[0026] The first step, the preparation of 1,4-dibromobutanedione

[0027]

[0028] The reaction substrate butanedione (50 g, 0.58 mol) was added to chloroform (500 mL), and liquid bromine (186 g, 1.16 mol) was added dropwise at 20-30°C, then heated to 50°C and stirred for 3 hours. Cool down to 0°C, continue to stir for 0.5 hours, then filter, and wash the solid with water (1000 mL ) to obtain the intermediate 1,4-dibromobutanedione (55 g, 0.23 mol). Yield 39%.

[0029] 1 HNMR (CDCl 3 , 400MHz): δ 4.27(s, 4H).

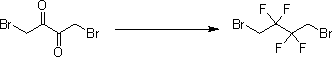

[0030] The second step, the preparation of 1,4-dibromo-2,2,3,3-tetrafluorobutane

[0031]

[0032] The intermediate 1,4-dibromobutanedione (15 g, 61.5 mmol) was cooled to -78°C, and sulfur tetrafluoride (30 g, 277.6 mmol) was introduced into it, then heated to 60°C and stirred for 3 hours. The reaction solution was dissolved in petroleum ether (100 mL), washed with saturated sodium bicarbonate (200 mL) and brine (100 mL) and spin-dried to obtain the intermed...

Embodiment 2

[0043] The first step, the preparation of 1,4-dibromobutanedione

[0044]

[0045]The reaction substrate diacetyl (50 g, 0.58 mol) was added to chloroform (500 mL), and liquid bromine (186 g, 1.16 mol) was added dropwise at 20-30°C, then heated to 60°C and stirred for 1 hour. Cool down to 0°C, continue to stir for 0.5 hours, then filter, and wash the solid with water (1000 mL ) to obtain the intermediate 1,4-dibromobutanedione (50 g, 0.21 mol). The yield is 35%.

[0046] 1 HNMR (CDCl 3 , 400MHz): δ 4.27(s, 4H).

[0047] The second step, the preparation of 1,4-dibromo-2,2,3,3-tetrafluorobutane

[0048]

[0049] The intermediate 1,4-dibromobutanedione (15 g, 61.5 mmol) was cooled to -78°C, and sulfur tetrafluoride (30 g, 277.6 mmol) was introduced into it, then heated to 80°C and stirred for 1 hour. The reaction solution was dissolved in petroleum ether (100 mL), washed with saturated sodium bicarbonate (200 mL) and brine (100 mL) and spin-dried to obtain the interme...

Embodiment 3

[0060] The first step, the preparation of 1,4-dibromobutanedione

[0061]

[0062] The reaction substrate diacetyl (50 g, 0.58 mol) was added to chloroform (500 mL), and liquid bromine (186 g, 1.16 mol) was added dropwise at 20-30°C, then heated to 70°C and stirred for 1 hour. Cool down to 0°C, continue to stir for 0.5 hours, then filter, and wash the solid with water (1000 mL ) to obtain the intermediate 1,4-dibromobutanedione (50 g, 0.21 mol). The yield is 35%.

[0063] 1 HNMR (CDCl 3 , 400MHz): δ 4.27(s, 4H).

[0064] The second step, the preparation of 1,4-dibromo-2,2,3,3-tetrafluorobutane

[0065]

[0066] The intermediate 1,4-dibromobutanedione (15 g, 61.5 mmol) was cooled to -78°C, and sulfur tetrafluoride (30 g, 277.6 mmol) was introduced into it, then heated to 70°C and stirred for 6 hours. The reaction solution was dissolved in petroleum ether (100 mL), washed with saturated sodium bicarbonate (200 mL) and brine (100 mL) and spin-dried to obtain the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com