Water-based coating for sports equipment and preparation method thereof

A technology of water-based paint and sports equipment, applied in the field of paint, can solve problems such as strong taste, not meeting the development prospects, and unsatisfied various indicators, and achieve the effect of simple steps, favorable for large-scale industrial production, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

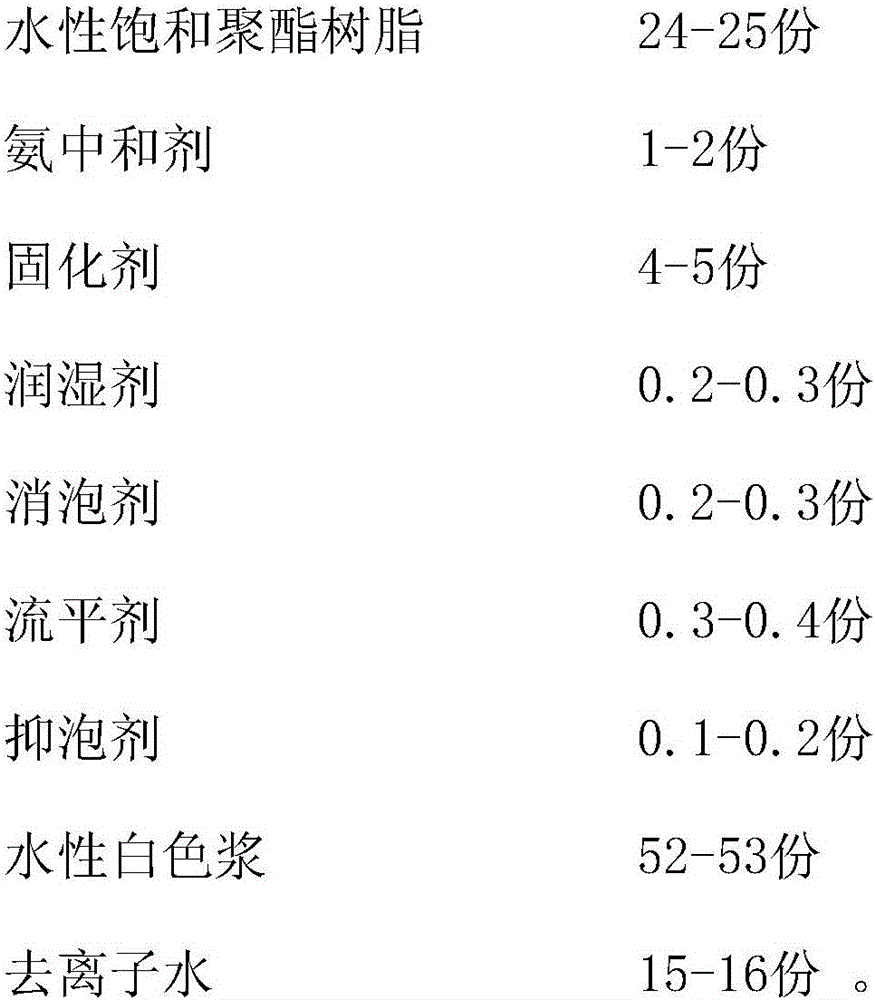

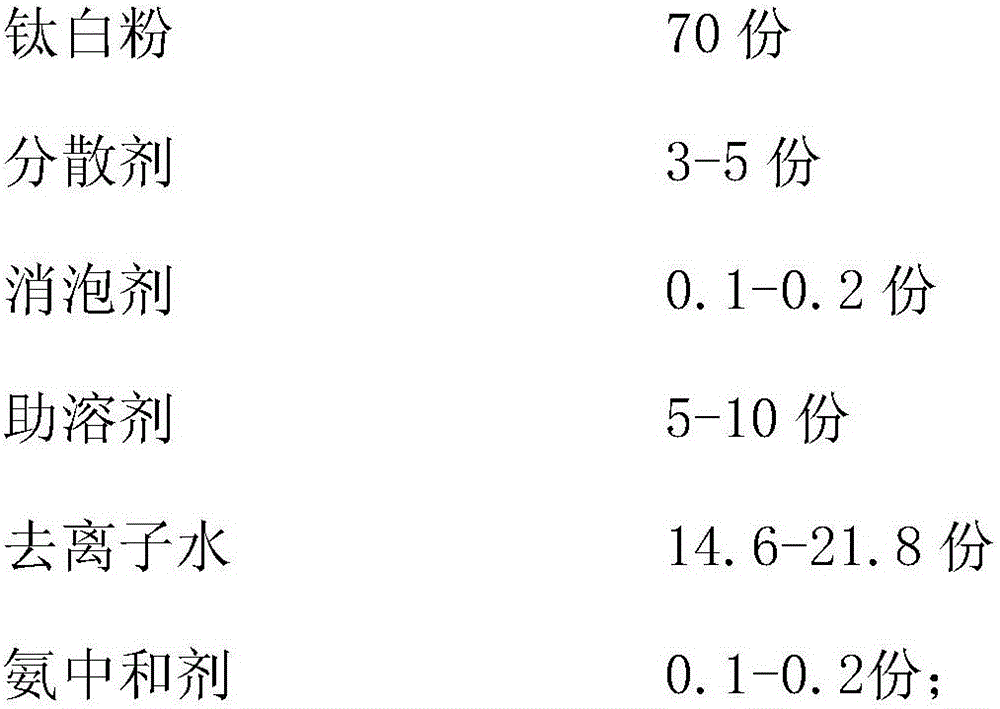

[0031] A water-based paint for sports equipment, the preparation method of the water-based paint, the steps are as follows:

[0032] 1) Add 24 parts of water-based saturated polyester resin into the container by weight, then stir with a high-speed disperser, gradually add 1 part of ammonia neutralizer dropwise while stirring, the stirring speed is 500r / min, after 3min, test the mixed liquid When the pH value is 7.8, stop stirring and proceed to the next step;

[0033] 2) Add 4 parts of INEOS-R747 methyl etherified amino resin curing agent, 0.2 parts of TEGO-270 wetting agent, 0.3 parts of EFKA-3772 leveling agent, 0.2 parts into the container Defoamer whose model is BYK-028, 0.1 parts of antifoamer whose model is Air Product-104E, and then stir with a high-speed disperser at a stirring speed of 500r / min, and disperse for 3 minutes;

[0034] 3) Add 52 parts of water-based white slurry to the container, and finally add 15 parts of deionized water, continue to disperse for 10 mi...

Embodiment 2

[0040] A water-based paint for sports equipment, the preparation method of the water-based paint, the steps are as follows:

[0041] 1) Put 25 parts of water-based saturated polyester resin into the container by weight, then stir with a high-speed disperser, gradually add 2 parts of ammonia neutralizer dropwise while stirring, the stirring speed is 700r / min, after 5min, test the mixed liquid When the pH value is 8.4, stop stirring and proceed to the next step;

[0042] 2) Add 5 parts of INEOS-R747 methyl etherified amino resin curing agent, 0.3 parts of TEGO-270 wetting agent, 0.4 parts of EFKA-3772 leveling agent, 0.3 parts into the container The model is BYK-028 defoamer, 0.2 part of the model is Air Product-104E foam inhibitor, and then stir with a high-speed disperser at a stirring speed of 700r / min, and disperse for 4 minutes;

[0043] 3) Add 53 parts of water-based white slurry to the container, and finally add 16 parts of deionized water, continue to disperse for 12 mi...

Embodiment 3

[0049] A water-based paint for sports equipment, the preparation method of the water-based paint, the steps are as follows:

[0050] 1) Add 24.4 parts of water-based saturated polyester resin into the container by weight, then stir with a high-speed disperser, gradually add 1.5 parts of ammonia neutralizer dropwise while stirring, the stirring speed is 900r / min, after 5min, test the mixed liquid When the pH value is 8.1, stop stirring and proceed to the next step;

[0051] 2) Add 4.5 parts of curing agent of INEOS-R747 methylated amino resin, 0.28 parts of wetting agent of model TEGO-270, 0.36 parts of leveling agent of model EFKA-3772, 0.24 parts of The model is BYK-028 defoamer, 0.15 parts of foam suppressor model is Air Product-104E, and then stir with a high-speed disperser at a stirring speed of 900r / min, and disperse for 5 minutes;

[0052] 3) Add 52.3 parts of water-based white slurry to the container, and finally add 15.8 parts of deionized water, continue to disperse f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com