Natural polysaccharide sponge and preparation method and application thereof

A natural polysaccharide and sponge technology, applied in the field of natural polysaccharide sponge and its preparation, can solve the problem of lack of sponge and achieve the effect of excellent biocompatibility and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] (1) Preparation of aldylated natural polysaccharides: Weigh 1 to 5 g of chondroitin sulfate, sodium hyaluronate or dextran, pour into deionized water, stir at room temperature until completely dissolved, and obtain a concentration of 1% (wt / v) polysaccharide aqueous solution; subsequently, add sodium periodate, add according to the ratio of natural polysaccharide and sodium periodate mass ratio being 1~10:1, avoid light and react for 1~3h; Then, add excess ethylene glycol, Terminate the reaction and continue to stir for 1-2 hours; finally, put the above solution into a dialysis bag, dialyze in ultrapure water for 3-6 days, and freeze-dry at -65°C to obtain the aldehydated natural polysaccharide solid powder. Refrigerate at -18°C until use.

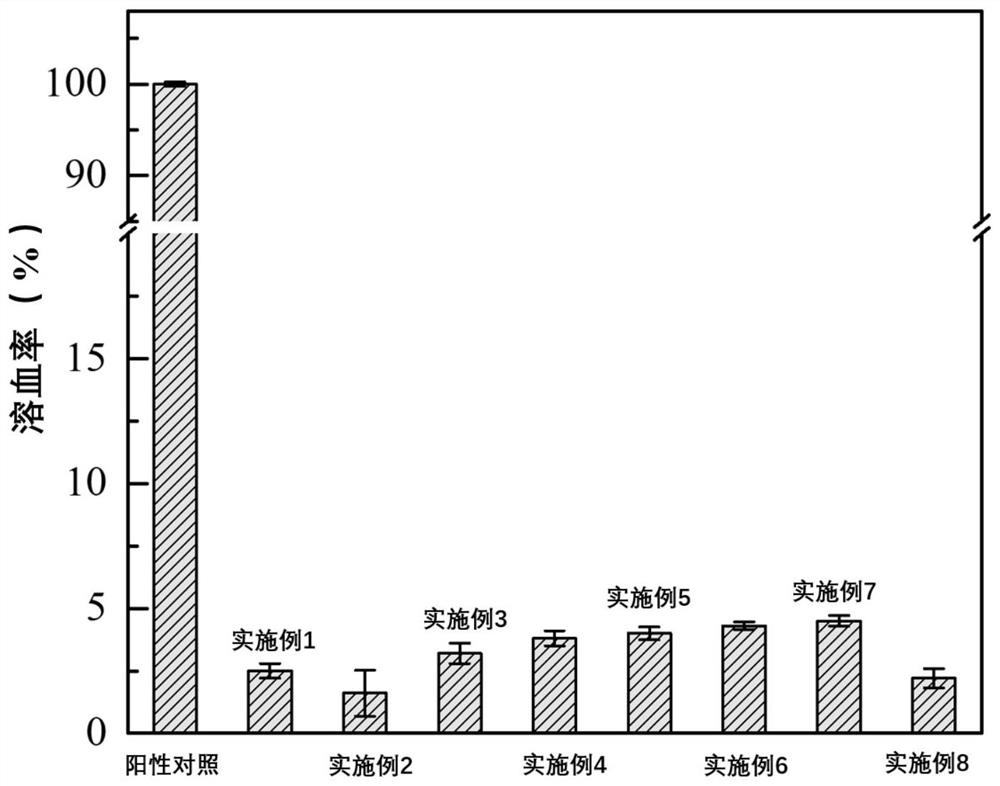

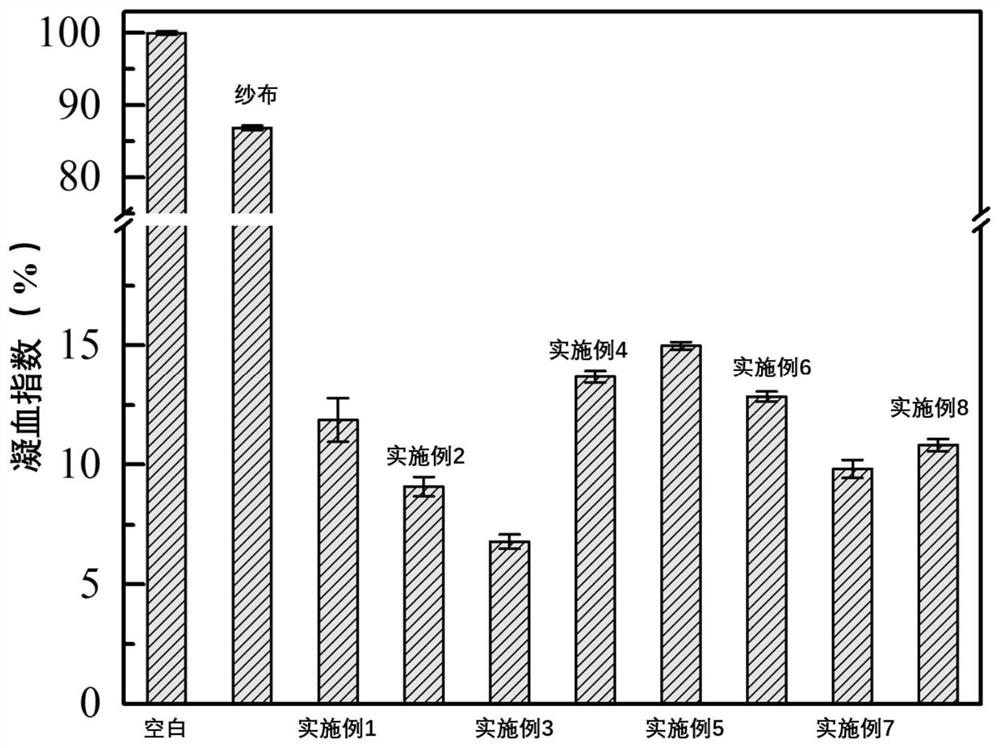

[0052] (2) Hemolysis rate test: take rabbit arterial blood, add 20mL PBS buffer (pH 7.4) to 10mL rabbit whole blood, mix gently and centrifuge the mixture at 3000rpm for 6 minutes. Then red blood cells (RBCs) were collected from t...

Embodiment 1

[0063] Preparation of natural polysaccharide sponge:

[0064] (1) carboxymethyl chitosan and kaolin are dissolved in normal saline to obtain solution A containing 2wt.% CMCS and 0.5wt.% KA;

[0065] (2) Prepare aldylated hyaluronic acid, wherein the mass ratio of sodium hyaluronate to sodium periodate is 1:1, the dark reaction time is 2h, the molecular weight cut-off of the dialysis bag is 3500, and the aldylated hyaluronic acid Dissolved in physiological saline to obtain a solution B containing 5wt.% aldylated hyaluronic acid;

[0066] (3) Mix solution A and solution B at a volume ratio of 3:7, and gel at room temperature for 12 seconds to obtain a hydrogel;

[0067] (4) The hydrogel was frozen at -80°C for 48 hours, and then freeze-dried to obtain a natural polysaccharide sponge.

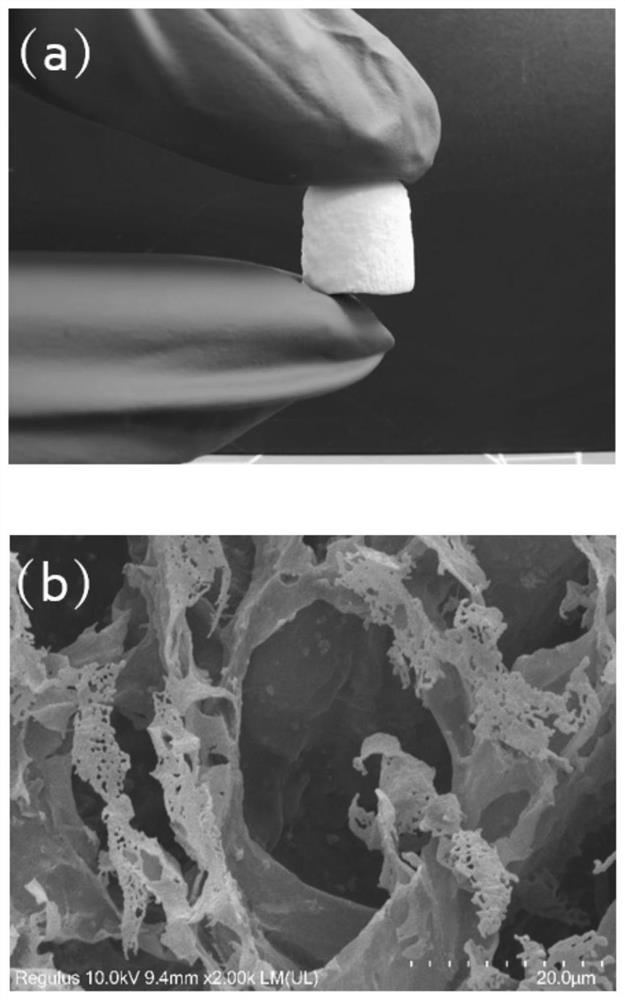

[0068] The natural polysaccharide sponge contains 14 parts by weight of carboxymethyl chitosan, 3.5 parts of kaolin, and 83 parts of aldylated hyaluronic acid. The physical figure and scanning ...

Embodiment 2

[0071] Preparation of natural polysaccharide sponge:

[0072] (1) carboxymethyl chitosan and kaolin are dissolved in normal saline to obtain solution A containing 4wt.% CMCS and 2wt.% KA;

[0073] (2) Preparation of aldylated chondroitin sulfate, wherein the mass ratio of chondroitin sulfate to sodium periodate is 3:1, the reaction time in the dark is 1h, the molecular weight cut-off of the dialysis bag is 8000-14000, and the aldylated chondroitin sulfate Dissolve chondroitin sulfate in normal saline to obtain a solution B containing 4wt.% formylated chondroitin sulfate;

[0074] (3) Mix solution A and solution B at a volume ratio of 5:5, and gel at room temperature for 125 seconds to obtain a hydrogel;

[0075] (4) The hydrogel was frozen at -80°C for 72 hours, and then freeze-dried to obtain a natural polysaccharide sponge.

[0076] The natural polysaccharide sponge contains 40 parts by weight of carboxymethyl chitosan, 20 parts of kaolin, and 40 parts of aldylated chondro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com