Steel cable comprehensive maintenance, cleaning and maintaining system of winch for boat

A comprehensive maintenance and winch technology, applied in the field of ships, can solve the problems of inability to protect steel cables from corrosion, low work efficiency, and environmental pollution, and achieve the effect of overcoming easy corrosion and short life, scientific and reasonable design, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

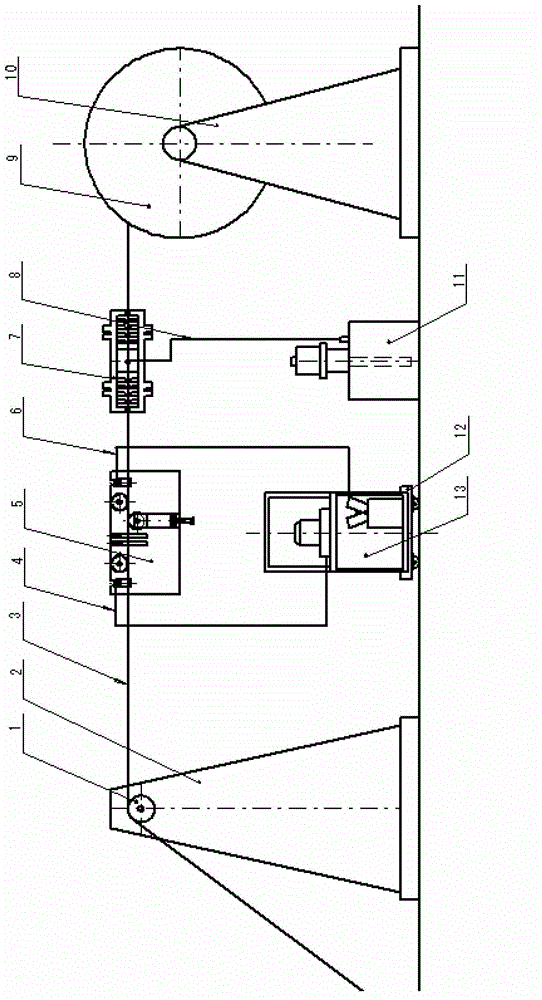

[0022] A comprehensive maintenance and cleaning system for marine winch steel cables, including a winch 9 and a guide wheel 1, the winch is installed on a winch support 10, and a guide wheel support 2 is fixed coaxially on the deck in front of the winch, and on the guide wheel support Guide wheel is installed, and steel cable 3 is wound on the sheave in the winch.

[0023] The innovation point of the present invention is:

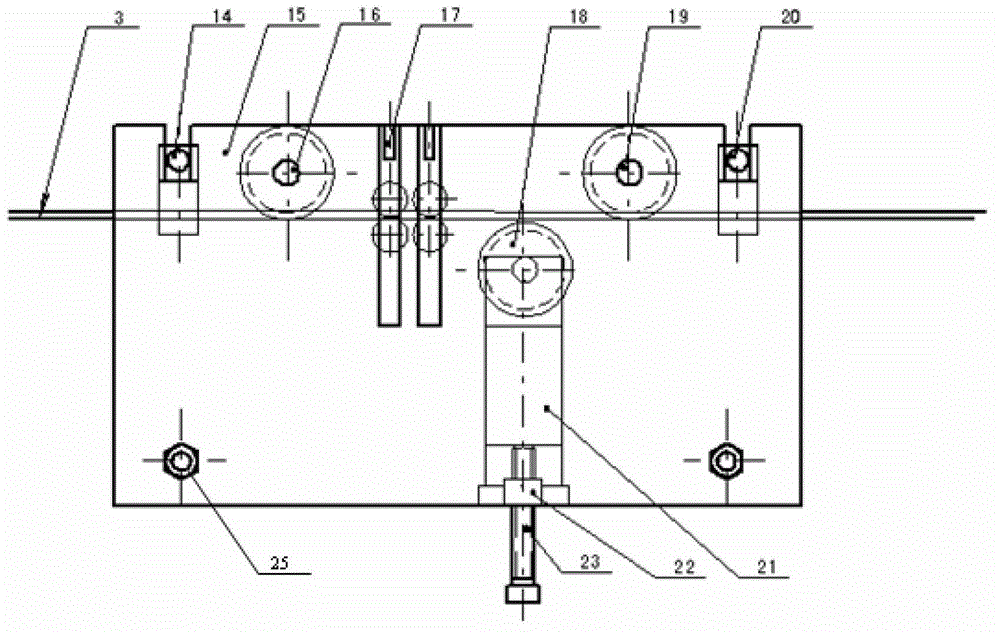

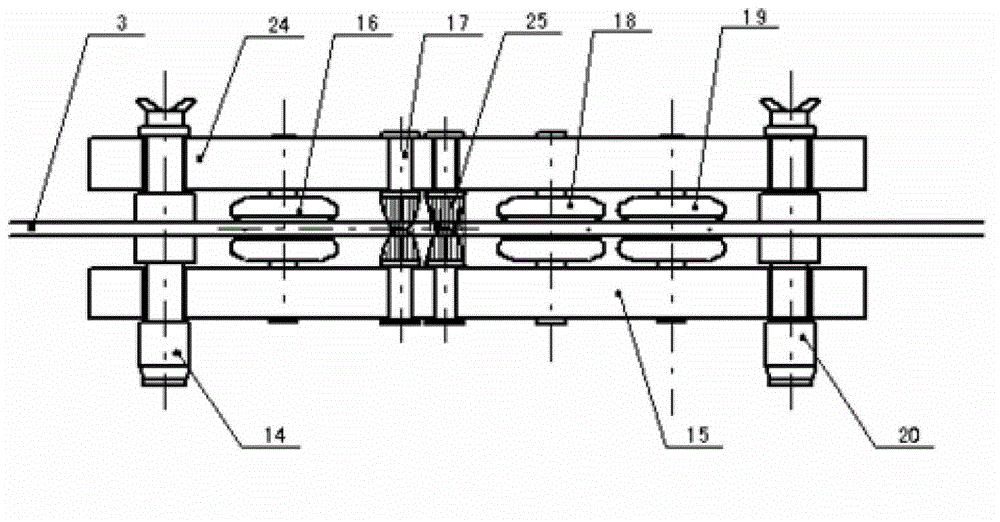

[0024] Set a cleaner 5 coaxially on the steel cable between the guide wheel and the winch, set an oiler 7 coaxially on the steel cable between the cleaner and the winch, and install a device on the deck corresponding to the cleaner Car 12, air compressor and booster water pump 13 are carried on this equipment ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com