Process and apparatus thereof for low-temperature cracking and high-temperature gasification of biomass

一种低温裂解、气化设备的技术,应用在气化工艺、粒状/粉状燃料气化、离析物等方向,能够解决难以清除焦油、化学能比例下降、有效气体含量低等问题,达到降低能耗及工程总投资、实现综合利用、解决局部结焦的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

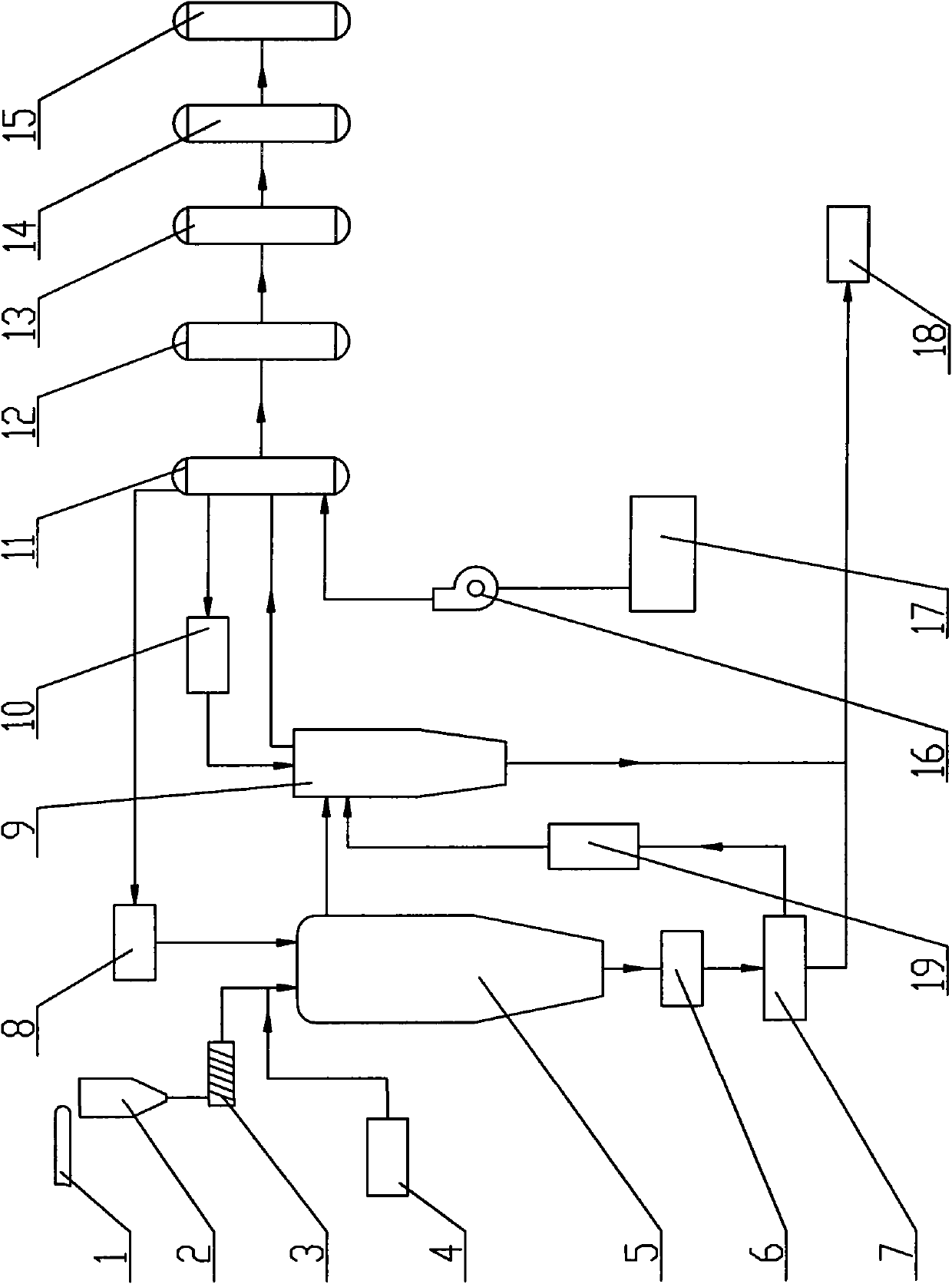

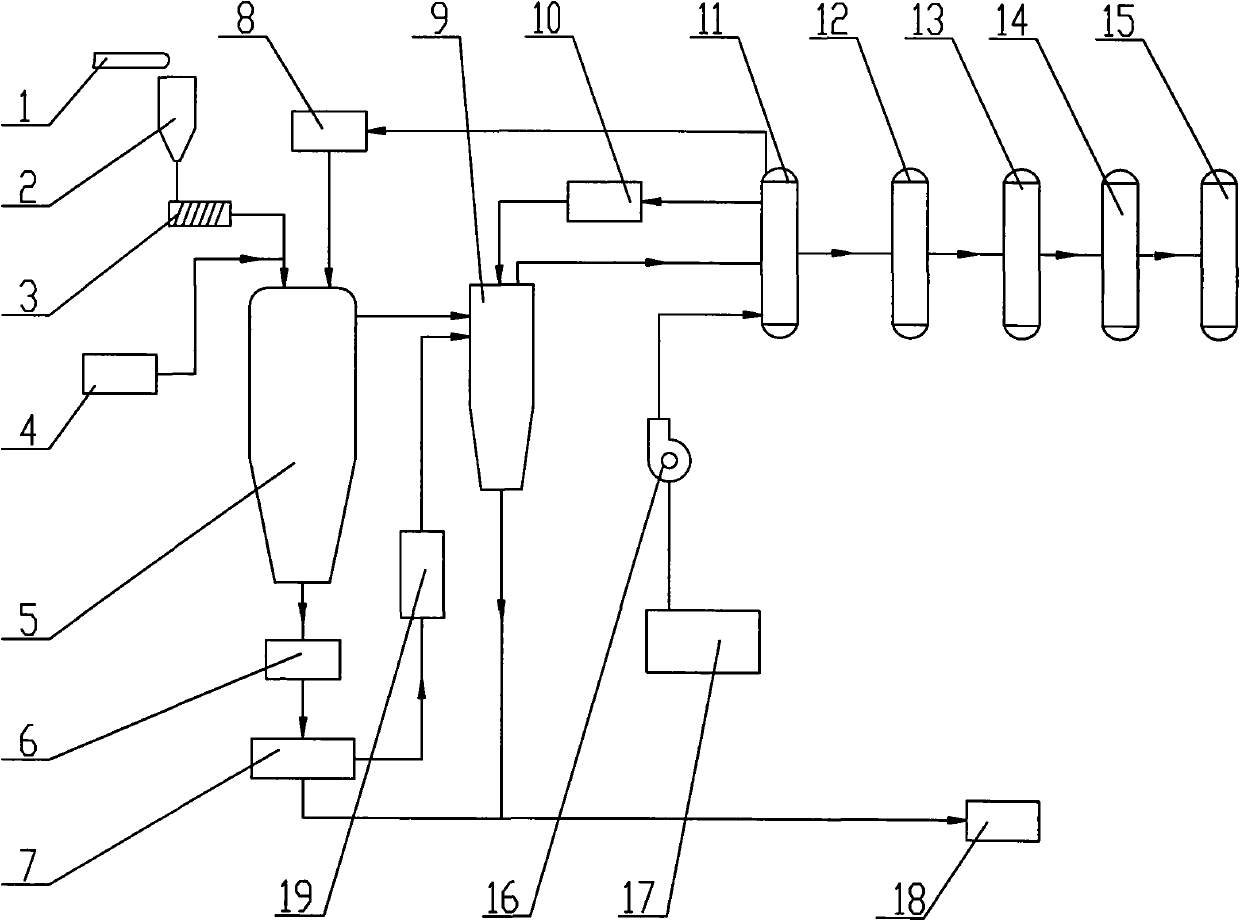

[0037] Below in conjunction with accompanying drawing and specific embodiment, equipment and technique of the present invention are described in further detail:

[0038] The biomass low-temperature pyrolysis high-temperature gasification equipment shown in the figure mainly includes a belt conveyor 1 for biomass transportation, an intermediate hopper 2 and a screw feeder 3, and a cracking furnace for accommodating biomass for pyrolysis and gasification reactions 5 and gasification furnace 9, for providing low-temperature plasma torch heater 8 and high-temperature plasma torch heater 10 of superheated steam for cracking furnace 5 and gasification furnace 9, for heating low-temperature plasma torch heater 8 and high-temperature plasma torch The water storage tank 17 and the water transfer pump 16 provided by the device 10, the heat exchanger 11 for the comprehensive utilization of heat energy, and the dust collector 12, the acid removal tower 13 and the dryer 14 for the subsequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com