A new type of rail grinding wheel based on rare earth materials and graphene

A technology based on graphene and rare earth materials, which is applied in the direction of bonded grinding wheels, abrasives, and metal processing equipment. It can solve problems such as poor quality of processed surfaces, obvious wear marks on rail surface, and low grinding effect of difficult-to-grind materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

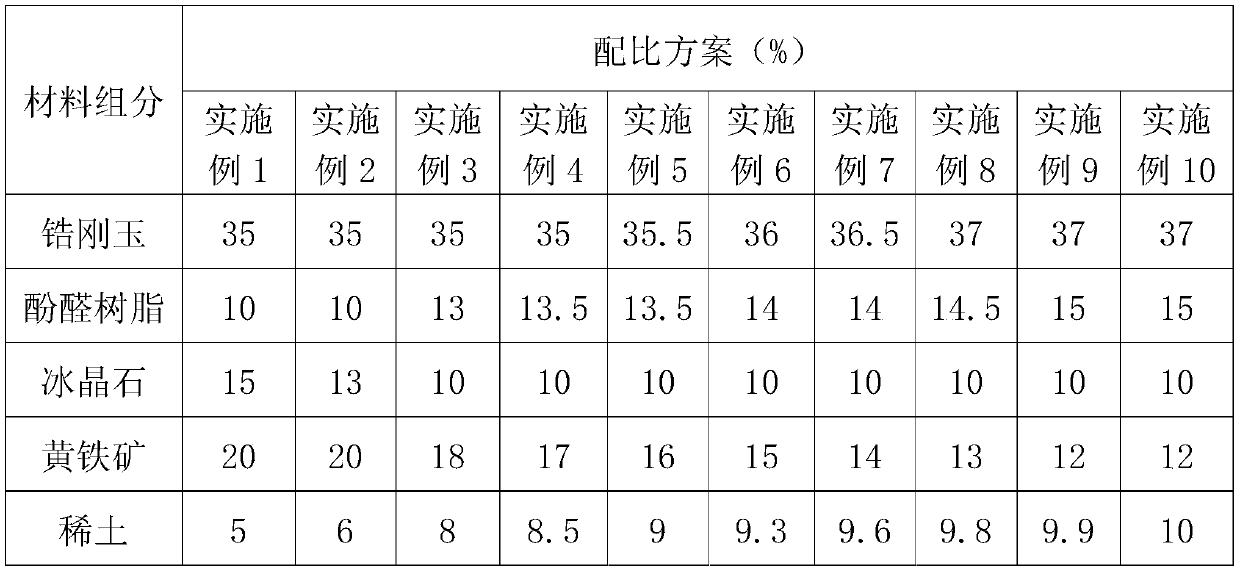

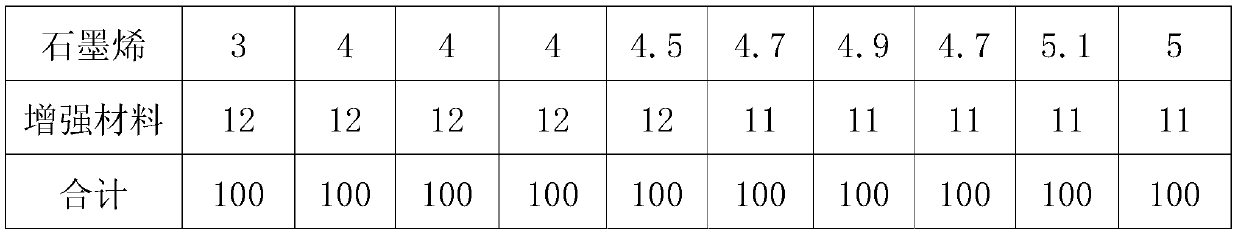

Embodiment 1

[0029] A novel rail grinding wheel based on rare earth materials and graphene bases, comprising a grinding wheel matrix and a grinding material. The grinding material includes abrasives, auxiliary materials, binders, wear-resistant additives, fillers and reinforcing materials, wherein the abrasives are weight Zirconium corundum with a proportion of 35%, the auxiliary material includes a rare earth with a weight proportion of 5% and a graphene with a weight proportion of 3%, and the binder is a phenolic resin with a weight proportion of 10%. The wear-resistant additive is cryolite with a weight ratio of 15%, the filler is pyrite with a weight ratio of 20%, and the reinforcing material is a chopped carbon fiber with a weight ratio of 12%.

[0030] The main test data of the obtained products are as follows:

[0031] The proportion of grinding times and output power: 1 time 30%; average grinding pressure: 1233.15N; average grinding wheel wear: 2483.9g, workpiece wear average: 20.31mm; ...

Embodiment 2

[0034] A novel rail grinding wheel based on rare earth materials and graphene bases, comprising a grinding wheel matrix and a grinding material. The grinding material includes abrasives, auxiliary materials, binders, wear-resistant additives, fillers and reinforcing materials, wherein the abrasives are weight Zirconium corundum with a proportion of 35%, the auxiliary material includes a rare earth with a weight proportion of 6% and a graphene with a weight proportion of 4%, the binder is a phenolic resin with a weight proportion of 10%, the The wear-resistant additive is cryolite with a weight ratio of 13%, the filler is pyrite with a weight ratio of 20%, and the reinforcing material is a chopped carbon fiber with a weight ratio of 12%.

[0035] The main test data of the obtained products are as follows:

[0036] The proportion of grinding times and output power: 1 time 30%; average grinding pressure: 1665.79N; average grinding wheel wear: 3905.7g, workpiece wear: 31.98mm; average ...

Embodiment 3

[0039] A novel rail grinding wheel based on rare earth materials and graphene bases, comprising a grinding wheel matrix and a grinding material. The grinding material includes abrasives, auxiliary materials, binders, wear-resistant additives, fillers and reinforcing materials, wherein the abrasives are weight Zirconium corundum with a proportion of 35%, the auxiliary material includes a rare earth with a weight proportion of 8% and a graphene with a weight proportion of 4%, and the binder is a phenolic resin with a weight proportion of 13%. The wear-resistant additive is cryolite with a weight ratio of 10%, the filler is pyrite with a weight ratio of 18%, and the reinforcing material is a chopped carbon fiber with a weight ratio of 12%.

[0040] The main test data of the obtained products are as follows:

[0041] The proportion of grinding times and output power: 4 times 30%; average grinding pressure: 2066.9N; average grinding wheel wear: 1744.6g, average workpiece wear: 30.2mm; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com