Method for forecasting rock blasting damage depth of nuclear power projects

A nuclear power engineering, deep technology, applied in the direction of blasting, electrical digital data processing, special data processing applications, etc., can solve the problems that group hole effect cannot be considered, pre-splitting blasting damage depth error, underlying bedrock damage is not large, etc. Achieve the effects of reducing the number of on-site tests, reducing the workload in the field, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

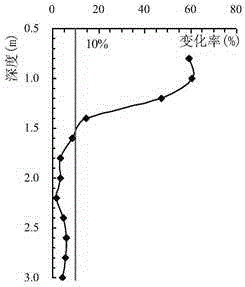

[0046] Example 1, such as figure 1 As shown, a method for predicting the blasting damage depth of rock mass in nuclear power engineering involves the following steps for the two blasting methods of step blasting and pre-splitting blasting:

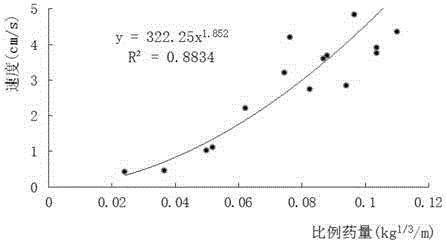

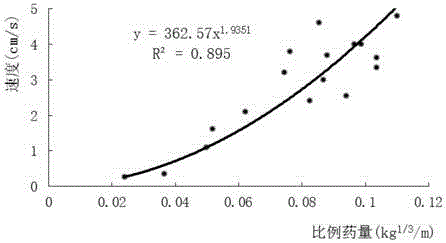

[0047] Step 1. Carry out blasting vibration tests on the site for blasting shots with a maximum charge range of 8-40kg, among which the number of blasting shots is 34; obtain the peak particle vibration velocity at different distances from the blast source for each shot The actual measured value, and then use the Sadowski formula for regression analysis to obtain the attenuation law of blasting vibration on the site.

[0048] For each blasting, arrange more than three measuring points at different distances from the blasting source in the area behind the blasting throwing direction (the distance of the blasting source at one of the measuring points is 40 meters), and arrange a measuring point at each place, and arrange a measuring point at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com