Vibration absorption device of adjustable natural frequency and engine with same

A natural frequency, engine technology, applied in the direction of non-rotational vibration suppression, mechanical equipment, vibration suppression adjustment, etc., can solve the problems of increased vibration of the main vibration structure, rapid decline of vibration absorption effect, practical application limitations of dynamic vibration absorbers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

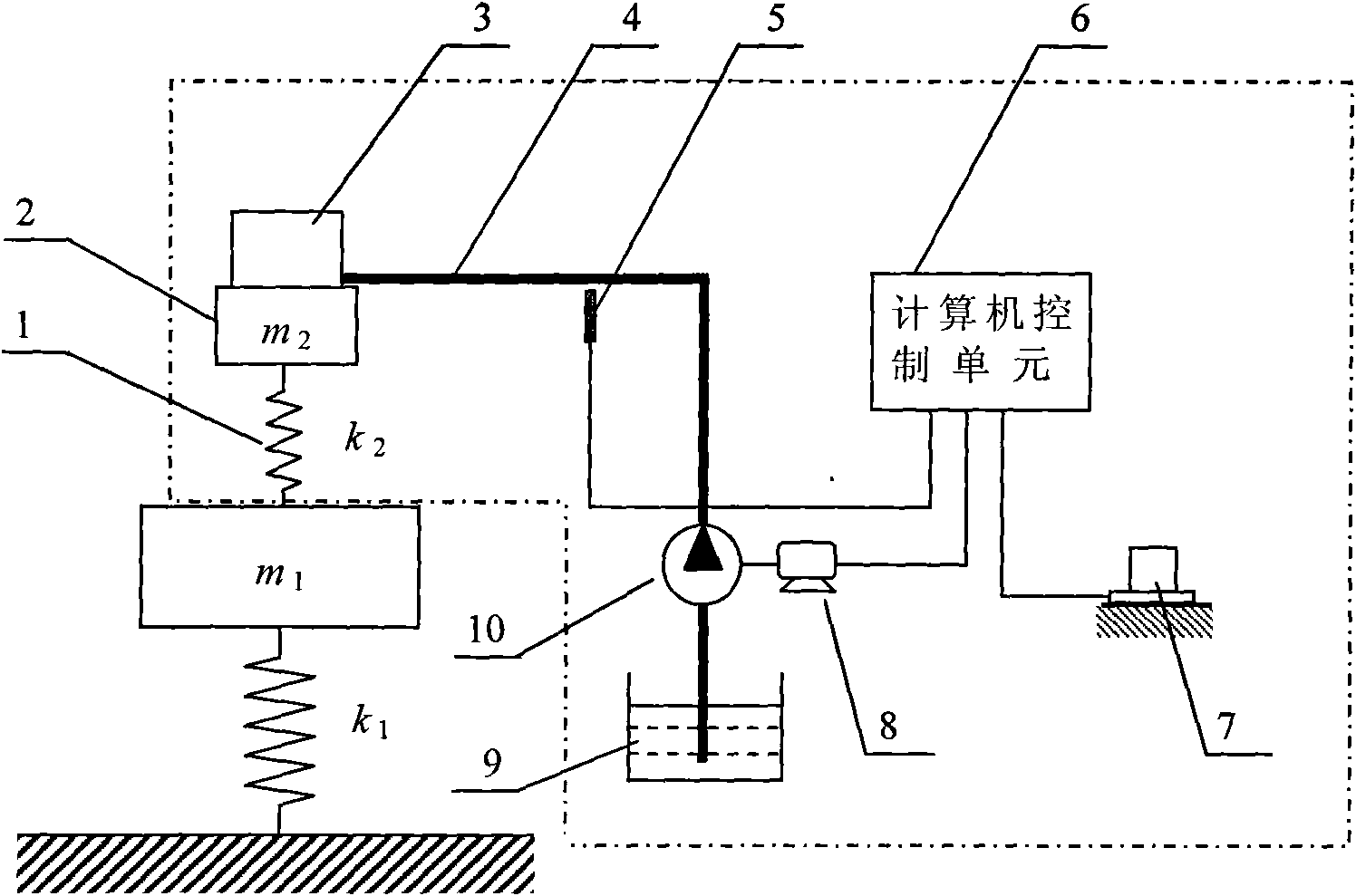

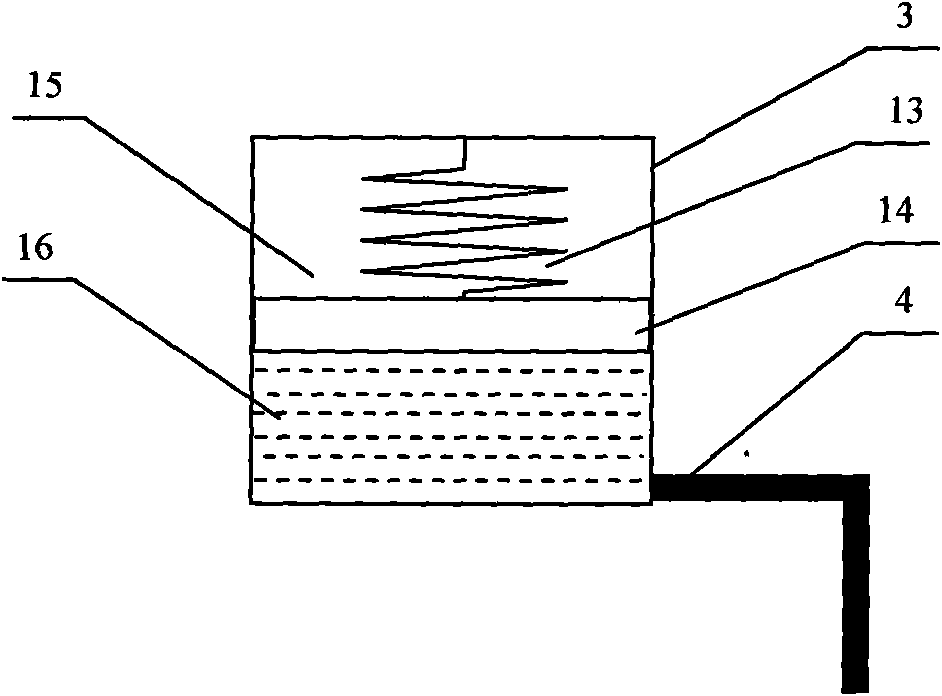

[0035] refer to figure 2 , is a vibration-absorbing device with adjustable natural frequency, mainly including a computer control unit 6, an acceleration sensor 7 for detecting the acceleration of the main vibration structure, a flow sensor 5 for measuring the flow rate of the liquid pump 10; a liquid storage tank 9, a liquid pump 10, and a vibration-absorbing spring 1. The vibration-absorbing mass 2 arranged on the upper end of the vibration-absorbing spring 1, the additional liquid tank 3 fixed on the vibration-absorbing mass 2; the additional liquid tank 3 is divided into an air upper chamber 15 and a liquid lower chamber 16 through a piston 14, and a liquid lower chamber 16 , the liquid pump 10, and the liquid storage tank 9 are connected by flexible pipes in turn. The computer control unit 6 receives the acceleration signal from the acceleration sensor, obtains the vibration frequency of the main vibration structure through Fourier transform, calculates and controls the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com