Detection test device of dynamic flexible drive torque

A technology of torque detection and flexible transmission, which is applied in the direction of force/torque/work measuring instrument, measuring device, rigid support of bearing components, etc., which can solve the influence of torque sensor detection value, torque detection device cannot popularize vibration platform, and affect torque Sensor detection accuracy and other issues, to achieve the effect of accurate torque value, convenient torque detection, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in detail below in conjunction with accompanying drawing:

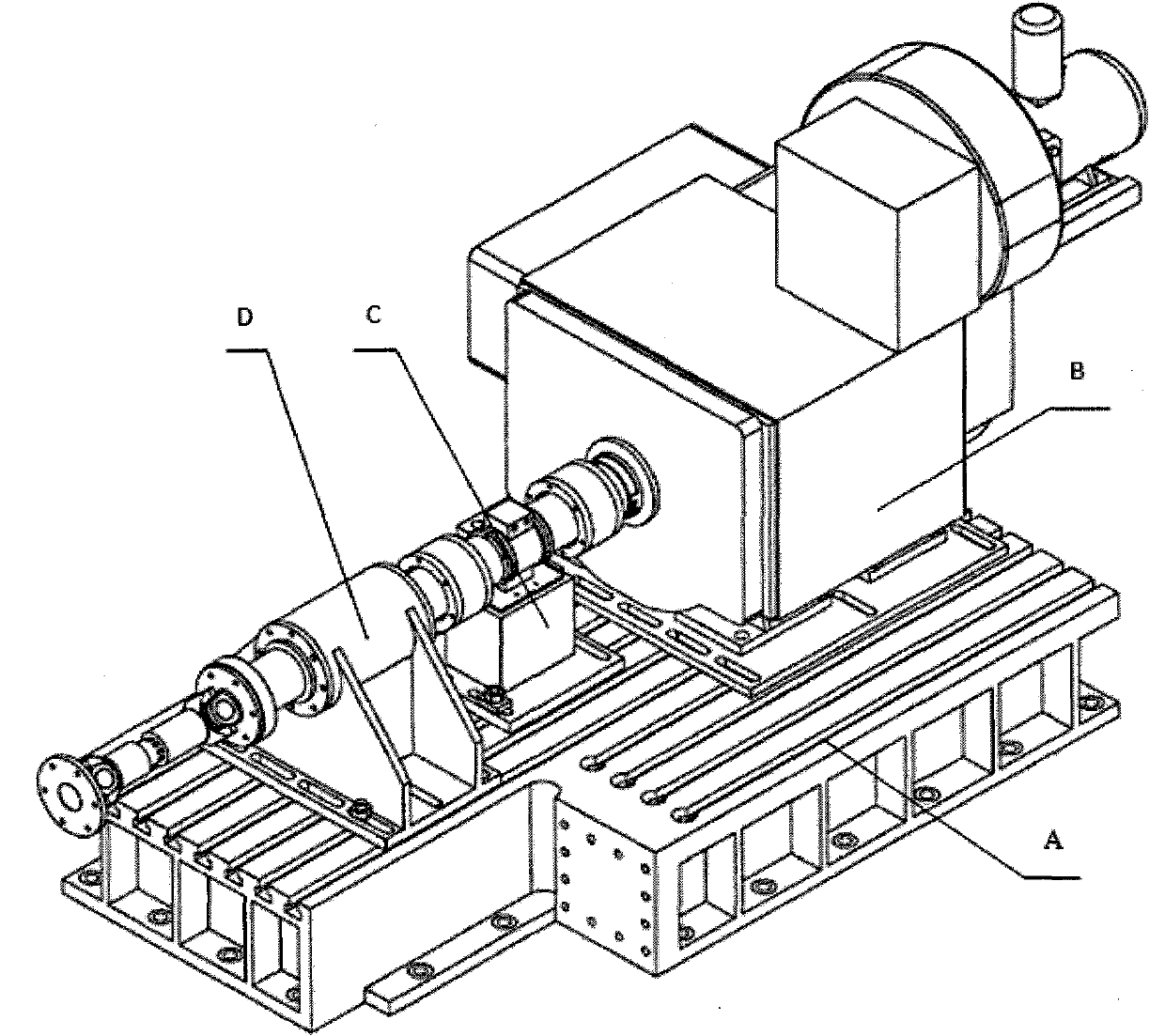

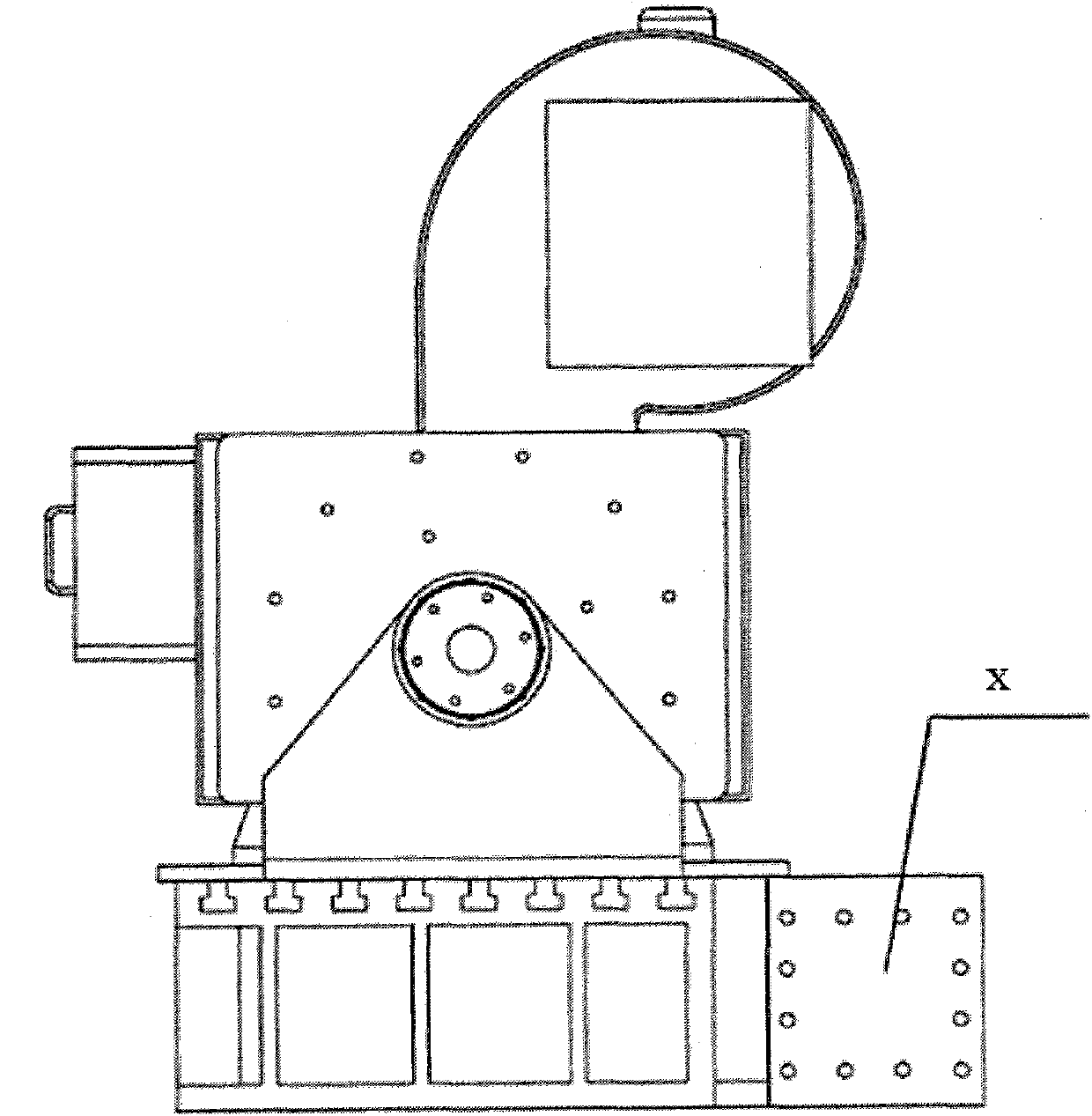

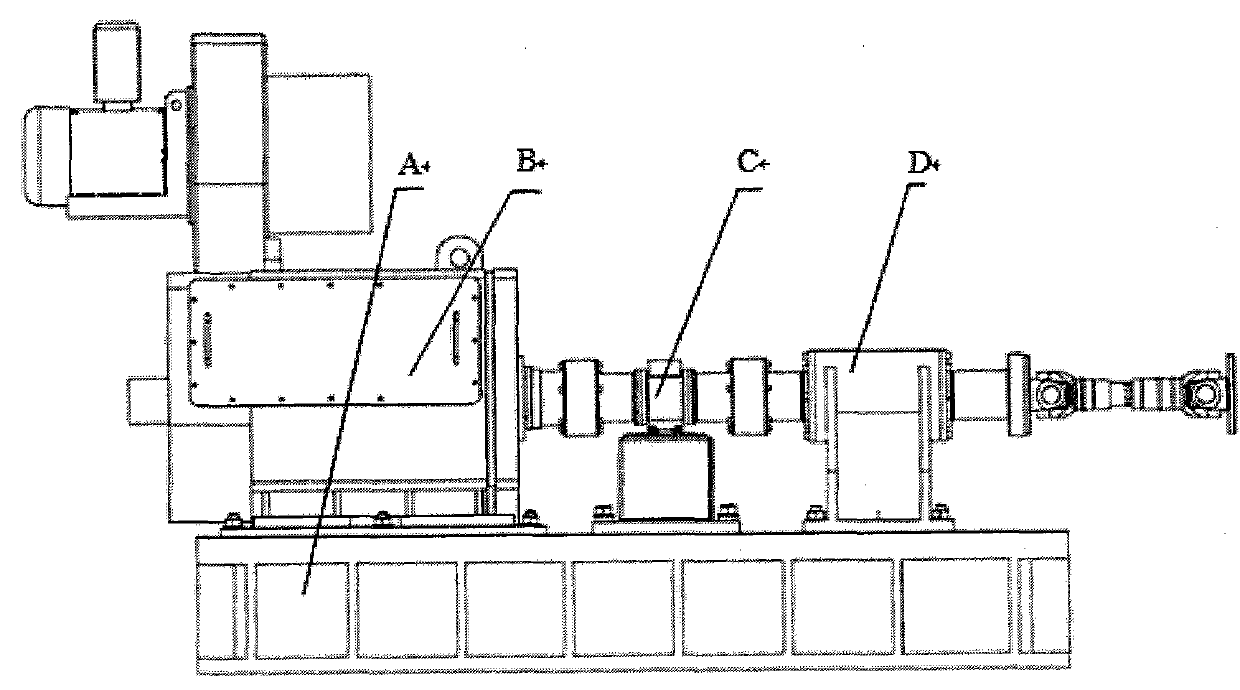

[0046] refer to Figure 1 to Figure 6 , the power flexible transmission torque detection test device is composed of a horizontal bearing platform A, a power output system B, a torque detection system C and a power transmission system D. The power output system B, the torque detection system C and the power transmission system D are all fixed on the horizontal bearing platform A through T-shaped bolts. The power output system B and the torque detection system C are connected by interference fit through the hydraulic safety coupling c and the elastic pin gear coupling e, and the torque detection system C and the power transmission system D are connected through the elastic pin gear coupling f connect.

[0047] The horizontal load-bearing platform A is a box structure welded by cast iron, cast steel or steel plate, and its upper surface is processed with T-shaped grooves. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com