Building structure foundation module having three-dimensional shock isolation and vibration attenuation functions

A technology for shock isolation and vibration reduction and building structure, which is applied in the direction of building components, buildings, building types, etc., can solve the problems of less earthquake energy, lack of vibration reduction and protection of the upper structure, hysteresis transmission, etc., and achieve the suppression of vibration and impact damage , Improve the effect of effective defense and disaster control, high vertical compression deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

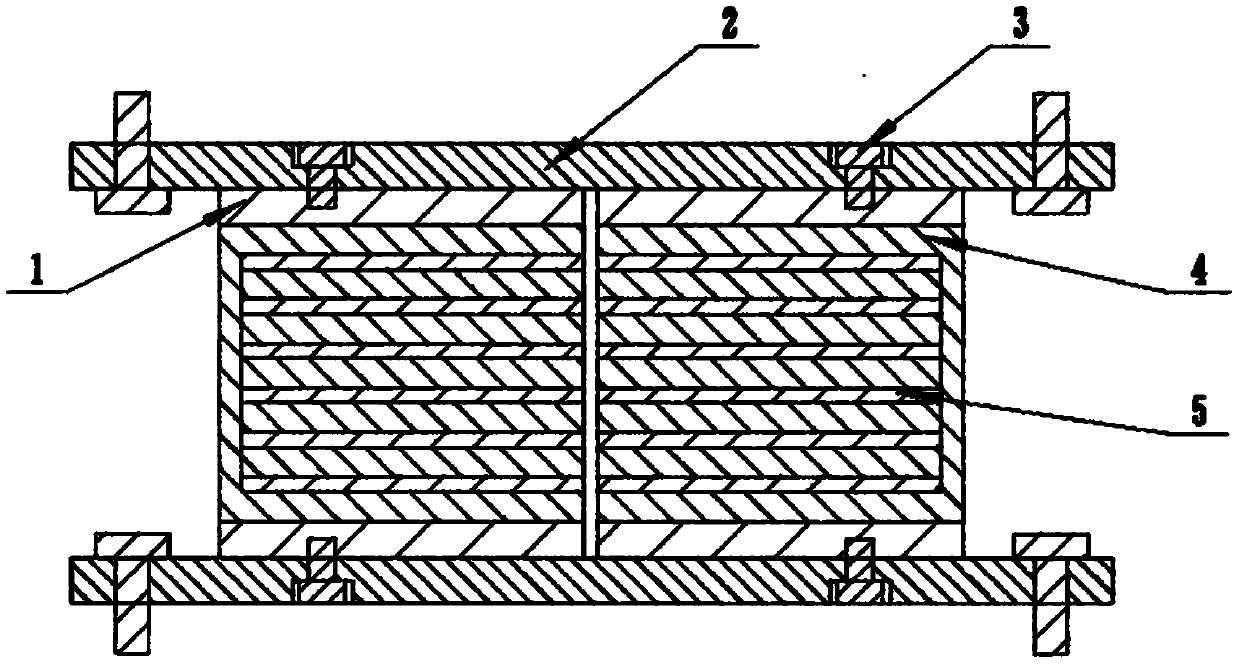

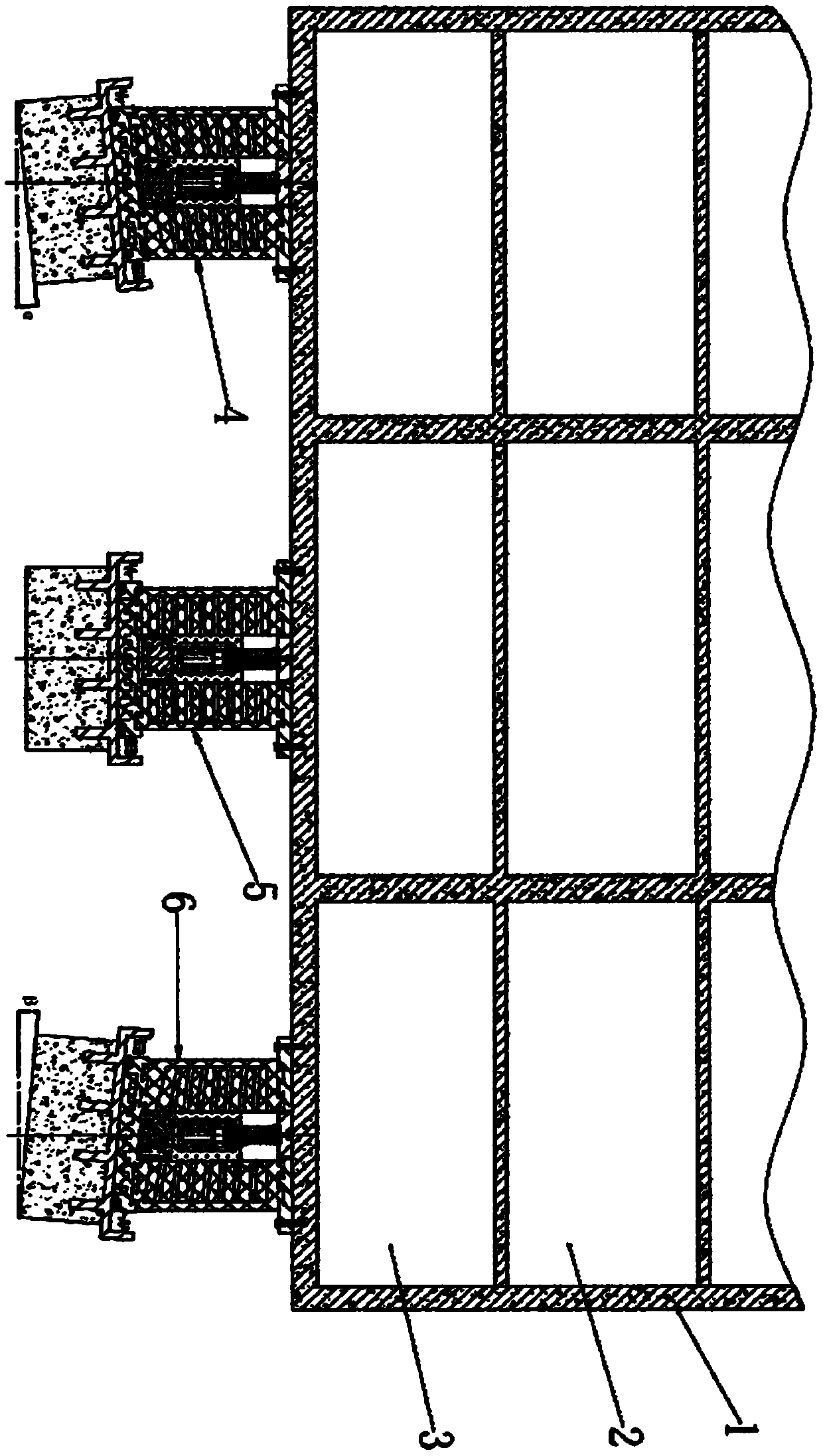

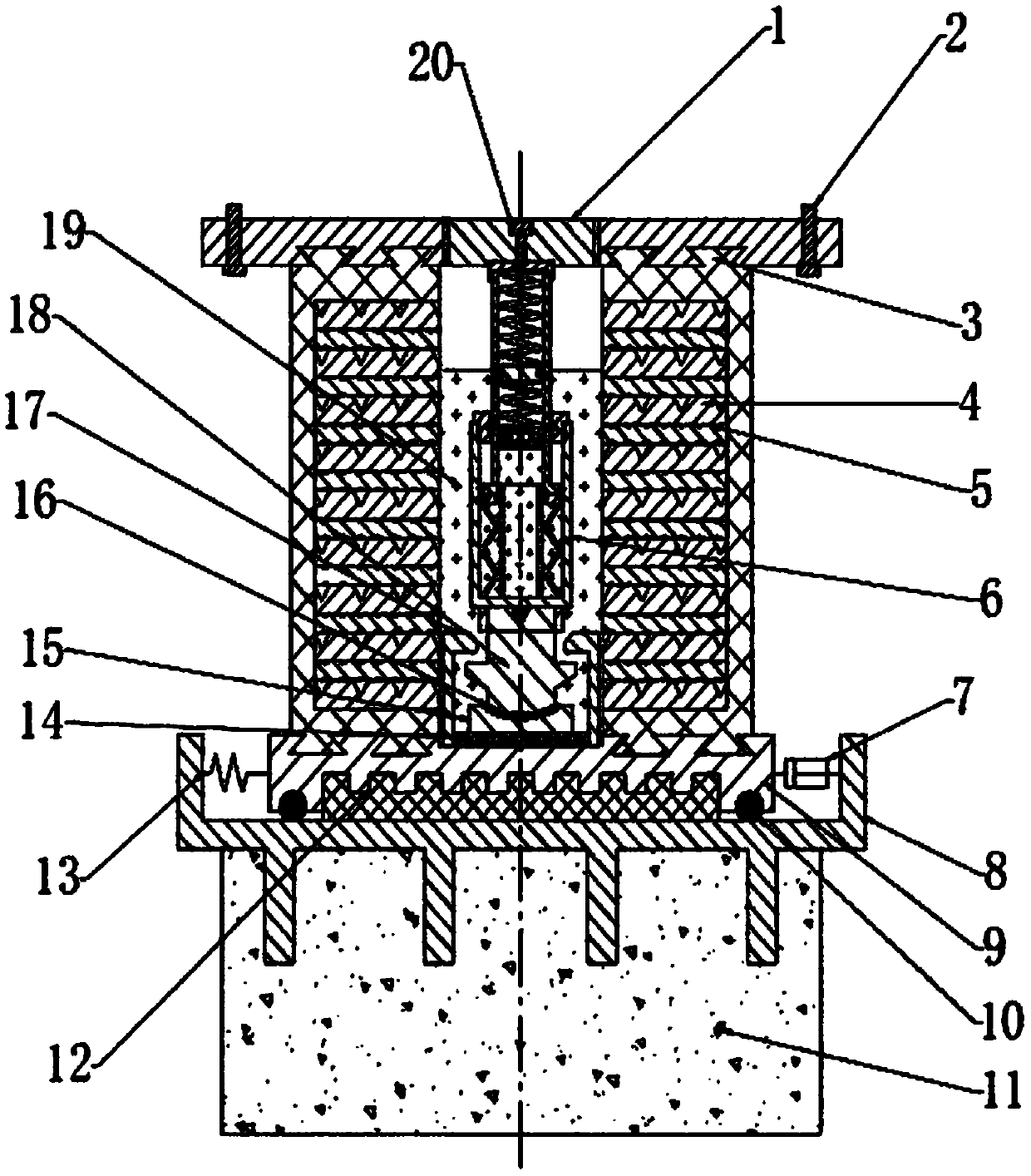

[0047] A building structural foundation module with three-dimensional vibration isolation and vibration reduction. The structural foundation module mainly includes the following four major functional components: a small steel structure platform (1) firmly connected to the reinforced concrete pile foundation. Its main technical features are: a small steel platform On the flat sliding support surface, a 3mm thick mirror stainless steel plate is used as the sliding friction pair material (F1); the bottom of the sliding support (2) located on the steel structure small platform (1) is embedded with HDPE / paraffin oil and self-lubricating. The composite material is used as the main sliding friction pair material (F2), and the sliding friction coefficient between the sliding friction pair (F1) / (F2) interface is less than or equal to 0.015 in the temperature range of -40~+28℃.

[0048] On the sliding support (2) is located a laminated special rubber / steel support (3) and a viscoelastic ene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com