Vibrating screen

A vibrating screen, horizontal technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of short service life of spring, poor screen vibration effect, uneven spring force, etc., to improve service life and increase screening efficiency. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The vibrating screen of the present invention will be described in detail below in conjunction with the accompanying drawings. Those skilled in the art should understand that the embodiments described below are only illustrative illustrations of the present invention, and are not intended to limit it in any way.

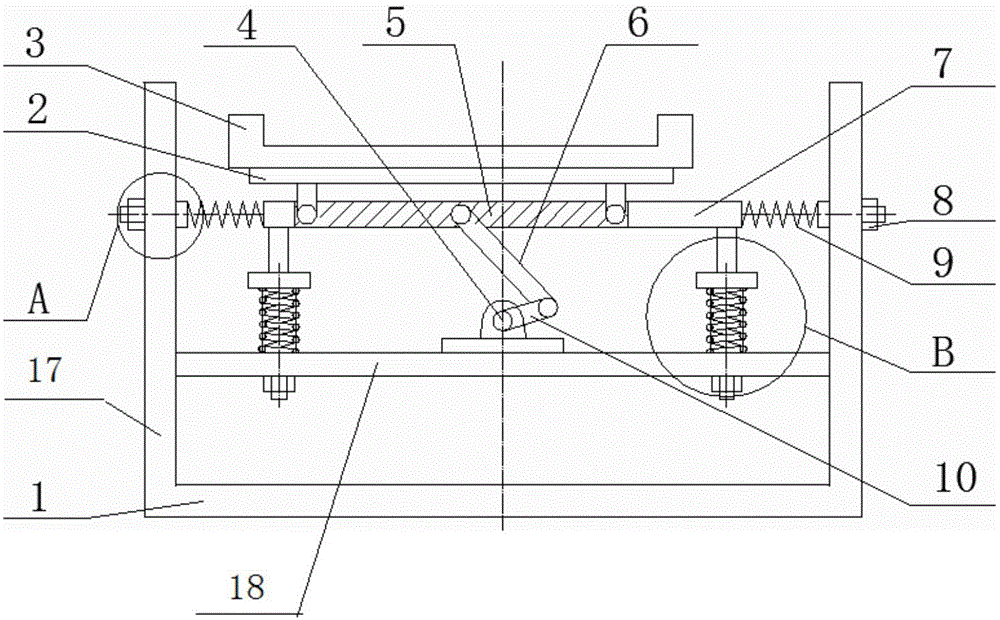

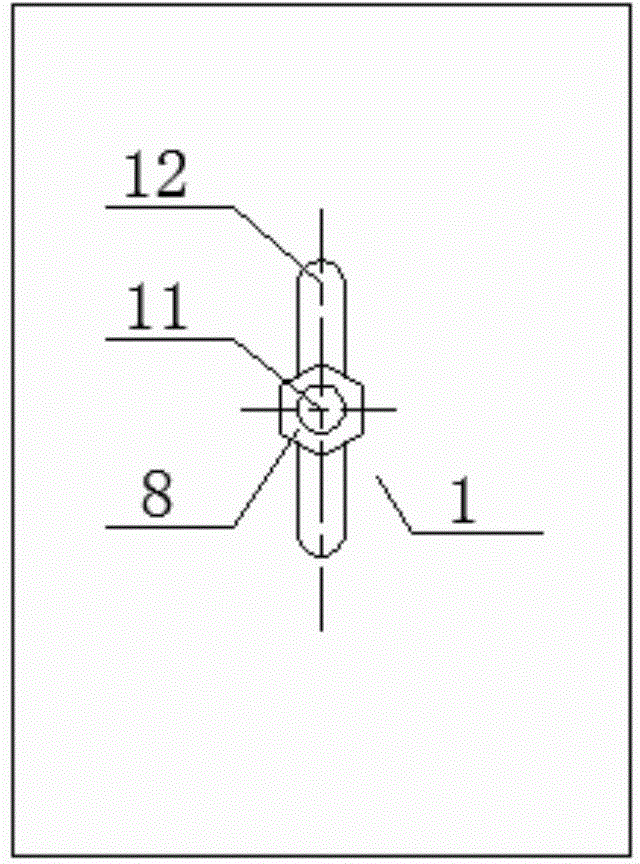

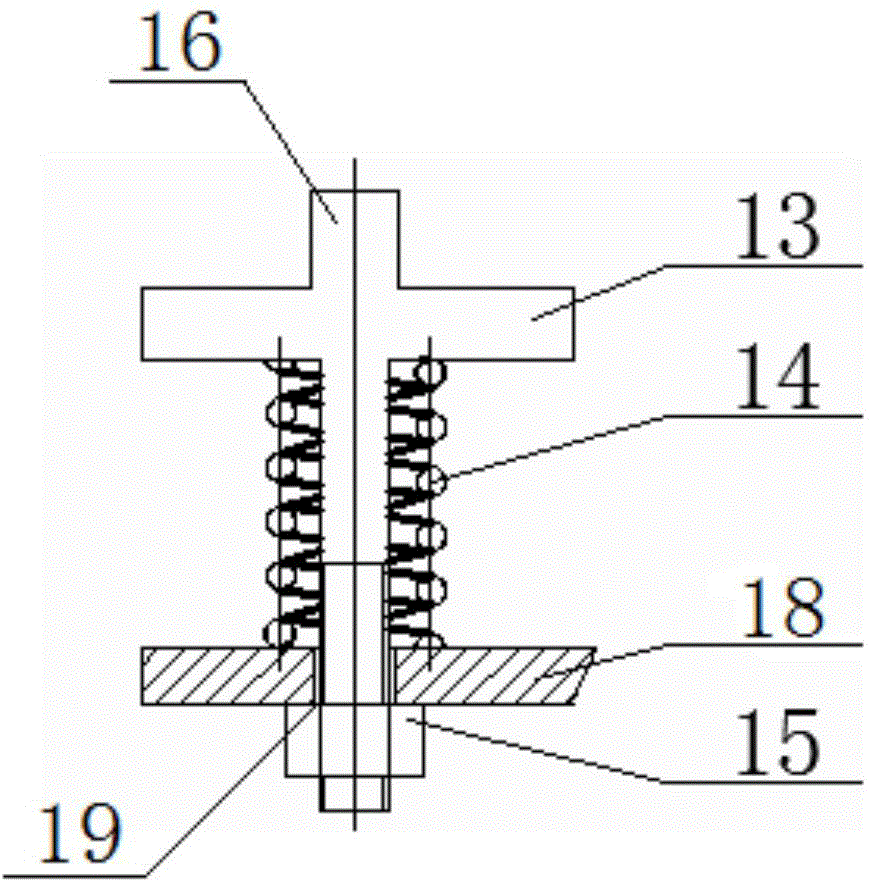

[0023] see figure 1 , The vibrating screen according to the present invention mainly includes a base 1, a horizontal damping mechanism A, a vertical support mechanism B, a horizontal guide rail 7, a bracket 2, a screen assembly 3 and a motor 4. The base 1 has a horizontal support portion 18 and a vertical support portion 17 , and the vertical support portions 17 are located at both ends of the horizontal support portion 18 . The horizontal damping mechanism A is connected to the vertical support portion 17 of the base 1, and the vertical support mechanism B is connected to the horizontal support portion 18 of the base 1. The horizontal guide rail 7 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com