Device and method of test for simulation of deep-lying tunnel blasting excavation unloading

A test device, excavation and unloading technology, applied in measurement devices, testing of machine/structural components, instruments, etc., can solve the problems of high cost of on-site prototype test, limited test conditions, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

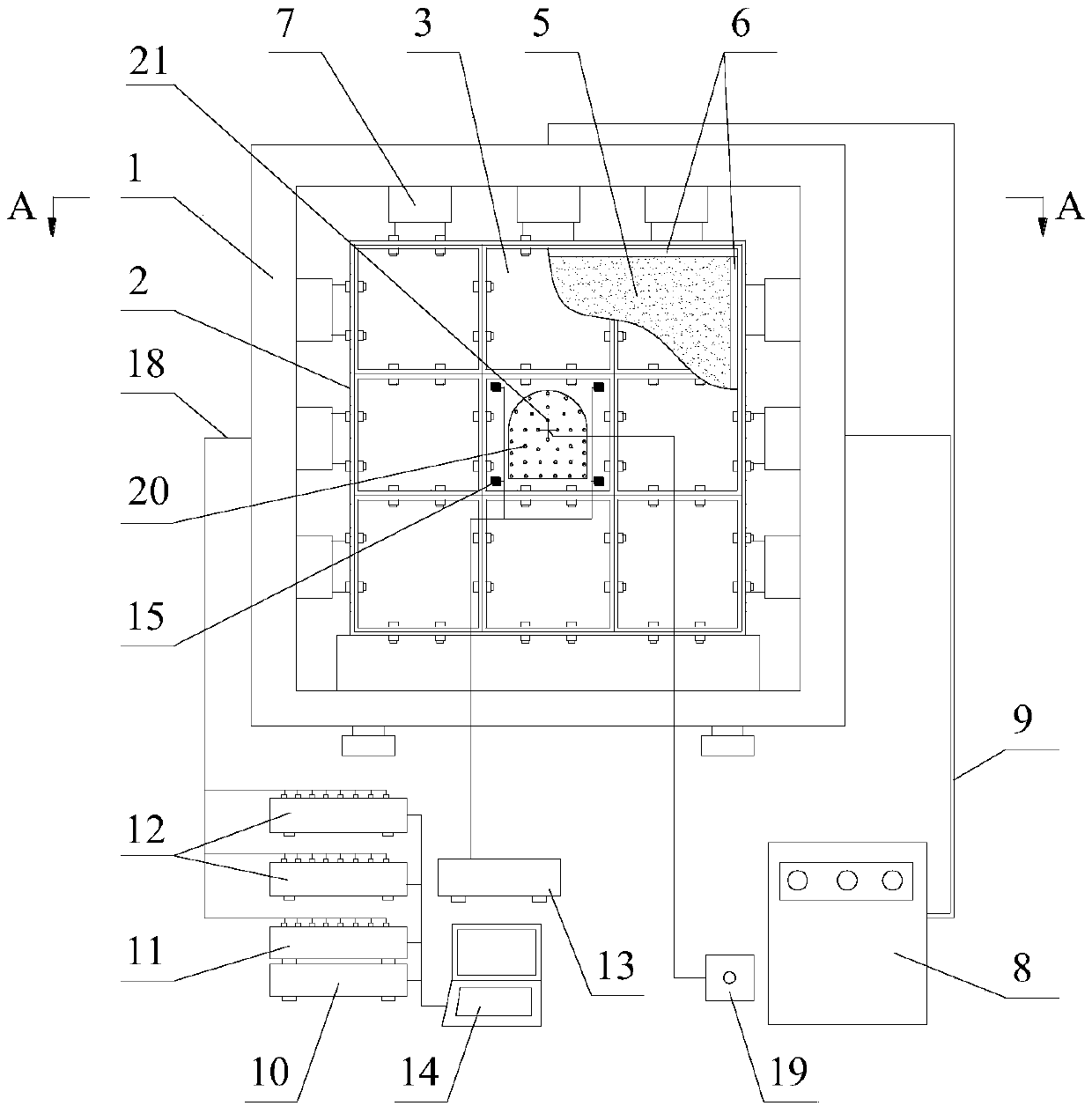

[0030] A test method for simulating the excavation and unloading of deep-buried tunnel blasting. A test device for simulating the unloading of deep-buried tunnel blasting and excavation is applied. The following test steps are followed:

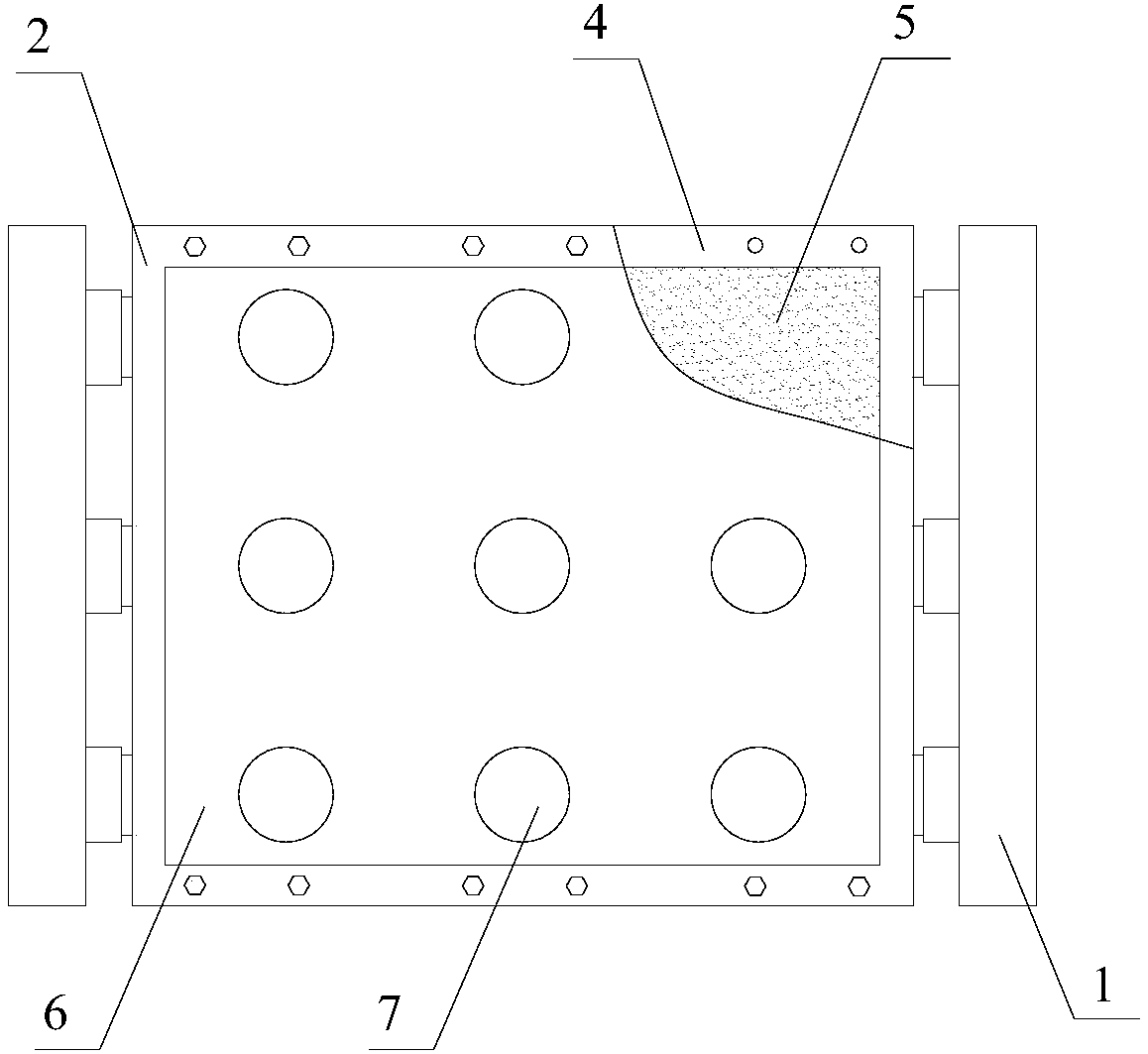

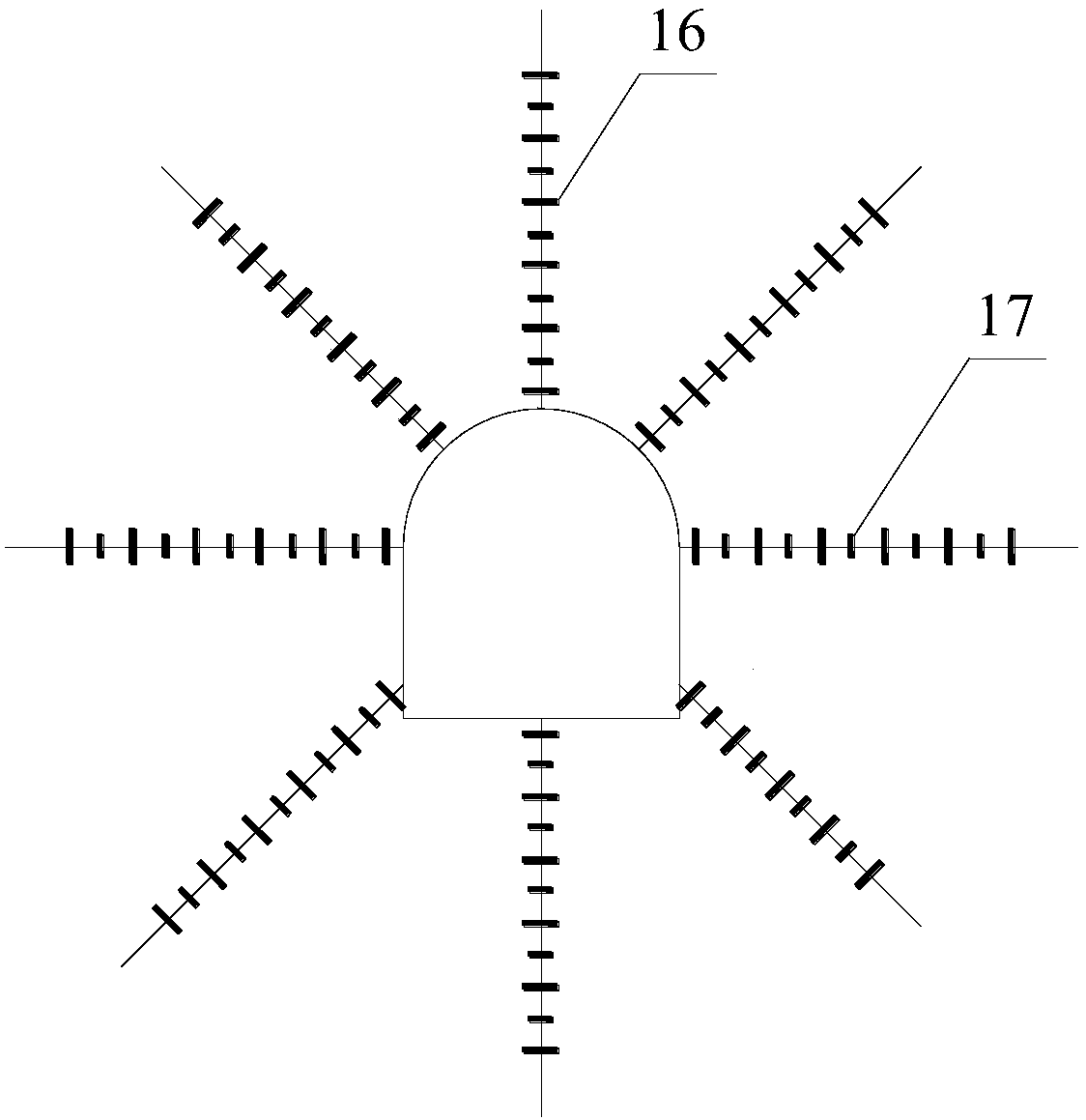

[0031] Step 1. Production of model sample 5: Determine the ratio of similar materials according to the tunnel blasted in the test plan, put the various materials into the mixer according to the ratio and mix them evenly, and then pour the mixed materials into the prepared In the sample mold of the sample, and according to the corresponding position of the model sample 5 in the test plan, the miniature pressure cell 16 and the resistance strain gauge 17 are buried;

[0032] Step 2. Installation of model sample 5: take out the consolidated model sample 5 from the mold, put it into the inner frame 2 of the model frame, and install pressure bearing plates on the upper, lower, left, and right sides of the model sample 5 6, and make the wire 18 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com