Method for controlling damage of slope pre-splitting blasting digging based on blast vibration test

A blasting vibration and pre-split blasting technology is applied in the damage control of slope pre-split blasting and excavation, and in the field of slope pre-split blasting and excavation damage control. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

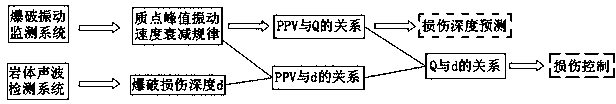

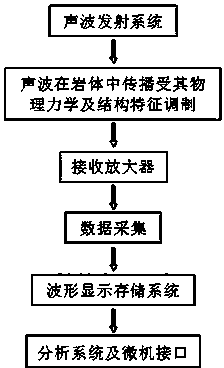

[0051] Through the following examples, combined with Figure 1-8 , the technical solution of the present invention will be further specifically described. A method for controlling damage of slope pre-splitting blasting excavation based on blasting vibration test of the present invention comprises the following steps:

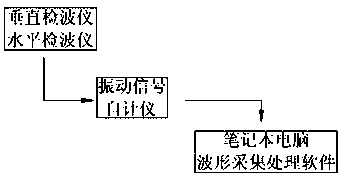

[0052] (1) Three-way vibration velocity sensor is used for monitoring. In the specific monitoring process, a three-way velocity sensor (which can measure vertical, horizontal radial and horizontal tangential vibrations at the same time) is arranged at the same measuring point of the key monitoring part, and fixed on the required monitoring point with plaster or other adhesives. The part, and then connect the vibration signal self-recorder with it. When the blasting vibration signal is transmitted to the measuring point, the vibration signal self-recorder automatically records the signal. After the explosion, use the blasting vibration analysis software that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com