Blasting vibration predicting method

A prediction method and blasting vibration technology, applied in blasting, measuring devices, geophysical measurements, etc., can solve the problems of not being able to know the blasting vibration frequency and blasting duration, and the analysis and evaluation of blasting vibration is not comprehensive enough, so as to optimize and adjust the blasting design , improve the accuracy and reliability, and improve the efficiency of vibration measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

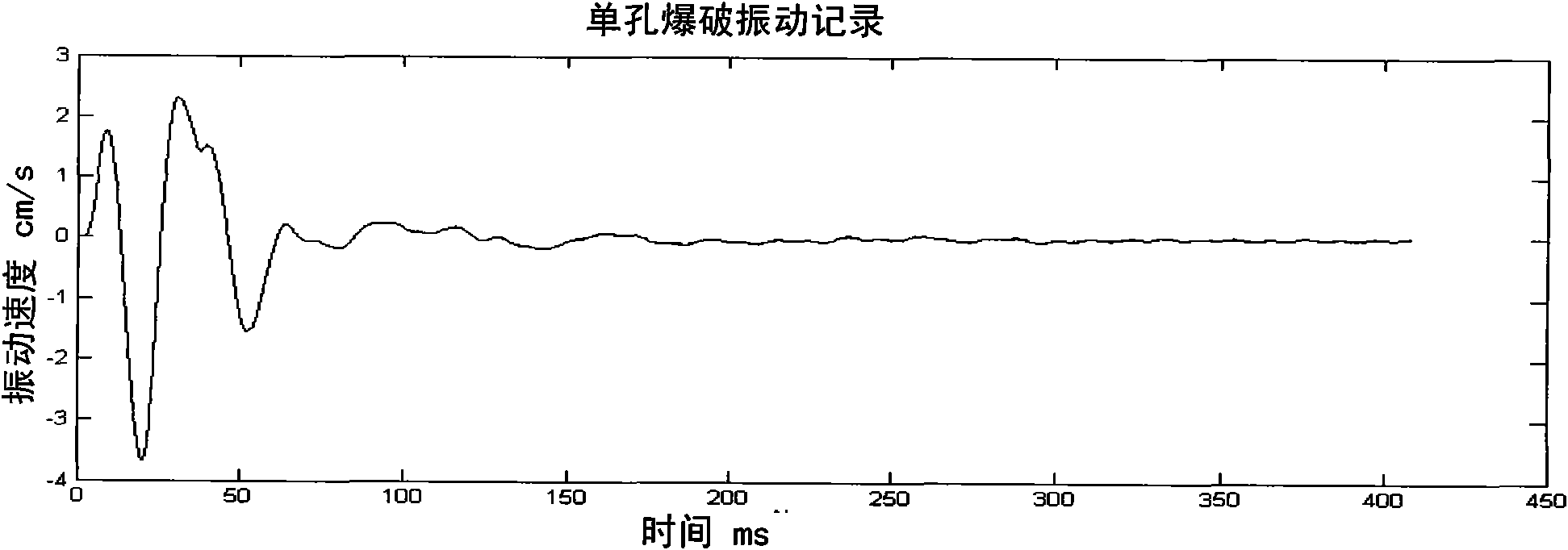

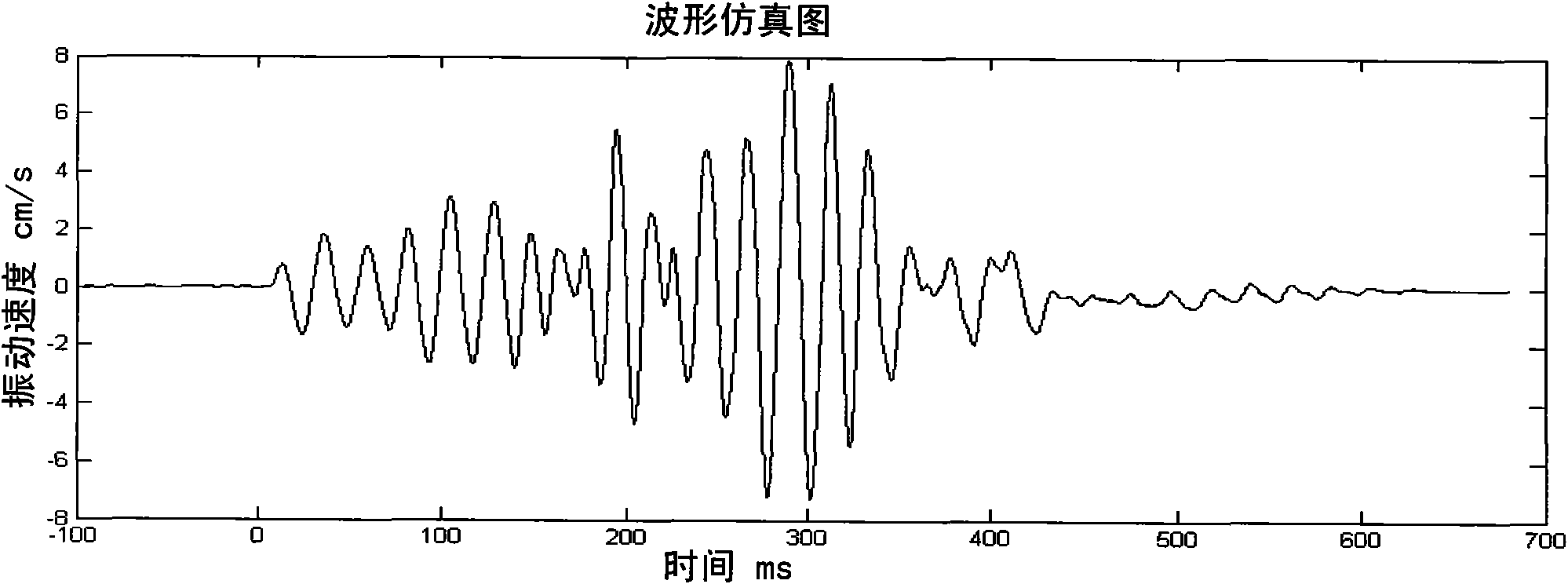

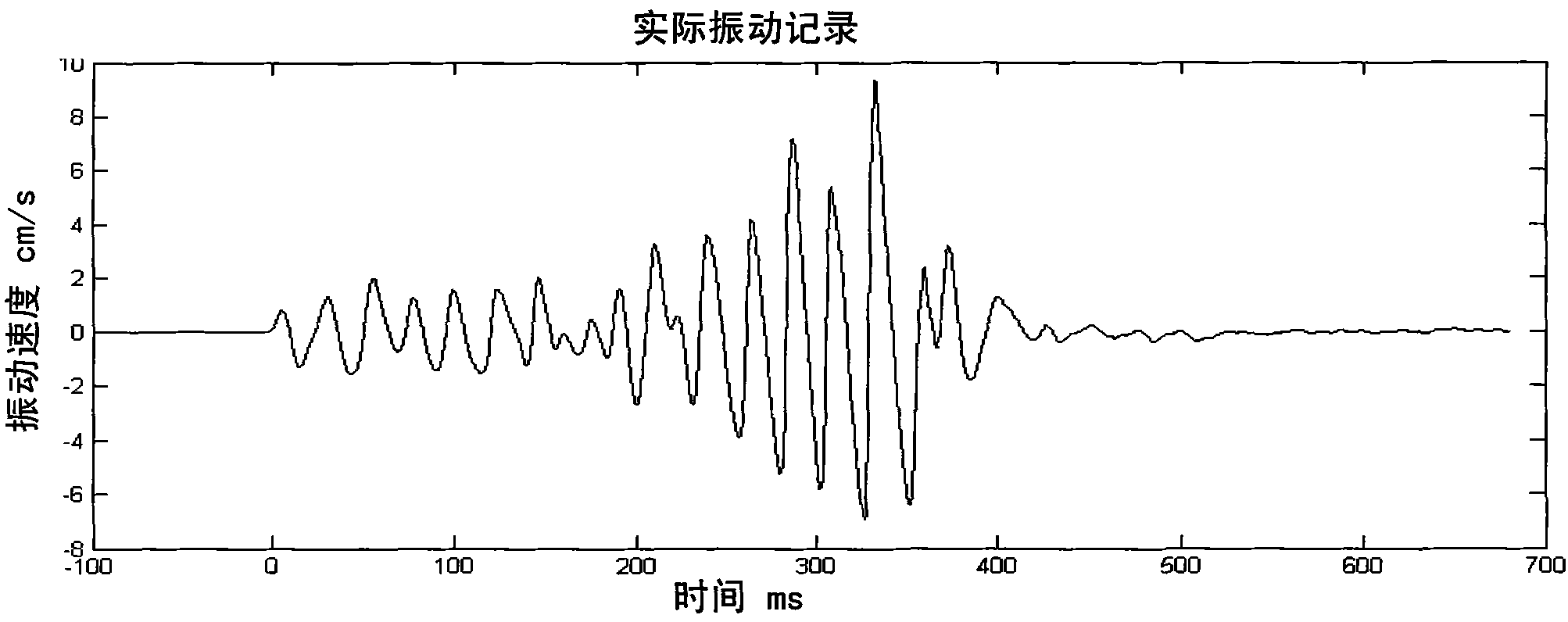

[0041] The blasting vibration prediction method provided by the present invention is carried out according to the following steps, see Figure 5 The schematic diagram of the implementation shown:

[0042] First, the position of the reference blast hole 200 and the charge amount of the hole 200 are determined near the blast area 100 . The location of the reference blast hole 200 should be selected as close as possible to the blast area 100 under the premise of ensuring that the blasting of the hole 200 will not affect the blast holes in the blast area 100 .

[0043] Second, at the location coordinates (u 0 , v 0 , r 0 ) to select at least one reference vibration measurement point on the line between the predicted target point 300 and the above-mentioned reference blast hole 200, for example Figure 5 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com