Controlled blasting construction method for shallow-buried large-section tunnel

A technology for controlling blasting and construction methods, applied in blasting and other directions, can solve problems such as excessive blasting vibration, slow progress, and unreliable results, and achieve the effects of speeding up construction progress, good social benefits, and reducing process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

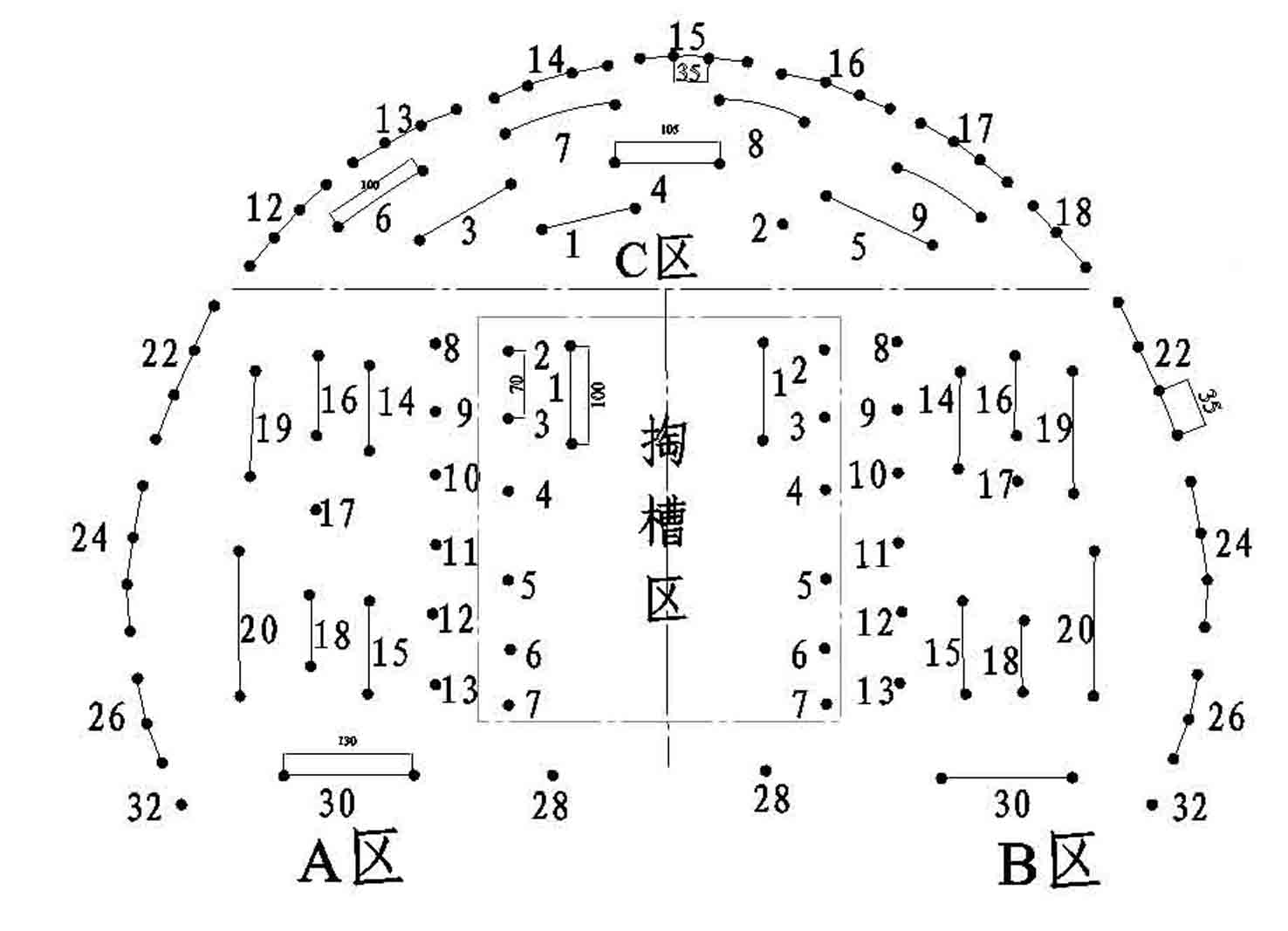

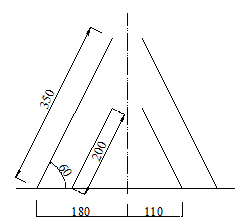

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

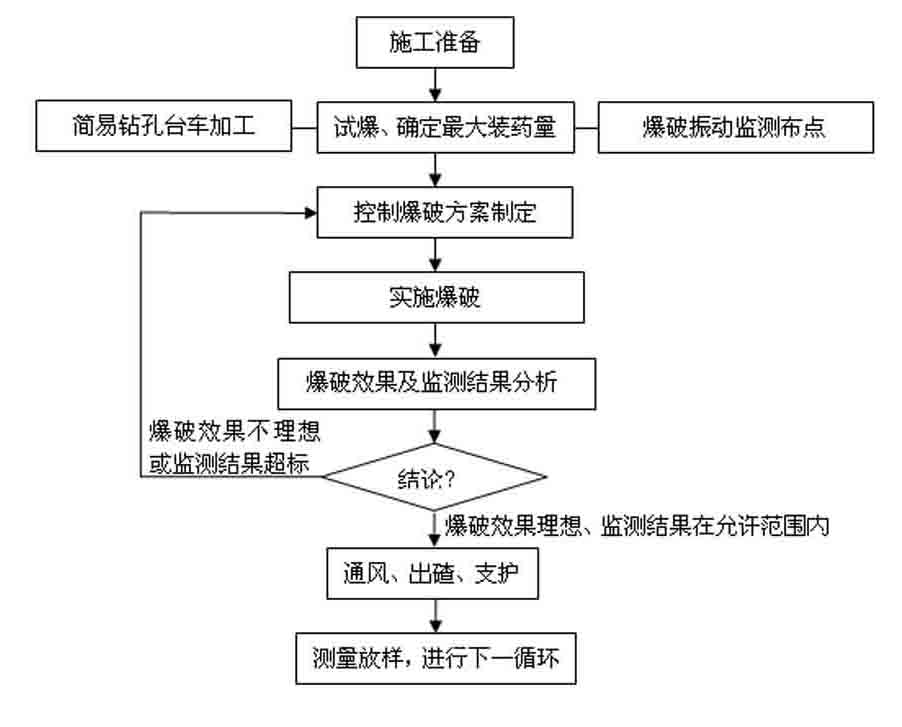

[0029] A kind of shallow-buried large-section tunnel control blasting construction method described in the present invention, such as figure 1 shown, including the following steps:

[0030] 1. Construction preparation

[0031] It is mainly the processing of simple drilling trolley. According to the tunnel excavation section size and construction habits, the full-section simple drilling jumbo is processed on site. It is required to install high-pressure air pipes and high-pressure water pipes on the trolley so that they can be directly connected to the air gun through gate valves and connecting hoses; the trolley is equipped with equipment such as power distribution boxes and lighting fixtures for convenient use during construction.

[0032] 2. Detonation test

[0033] The ultimate purpose of the blasting test is to determine the maximum charge per delay detonator i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com