Novel roadway blasting construction method

A technology of broken bodies and cutting holes, which is applied in blasting and other directions, and can solve problems such as crowding, affecting the effect of cutting, affecting the effect of blasting, and the scale of excavation, so as to achieve the effect of strengthening rock throwing and improving blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In conjunction with the accompanying drawings and examples, the brand-new shaft blasting construction method of the present invention is described as follows:

[0015] Take the circular shaft section as an example:

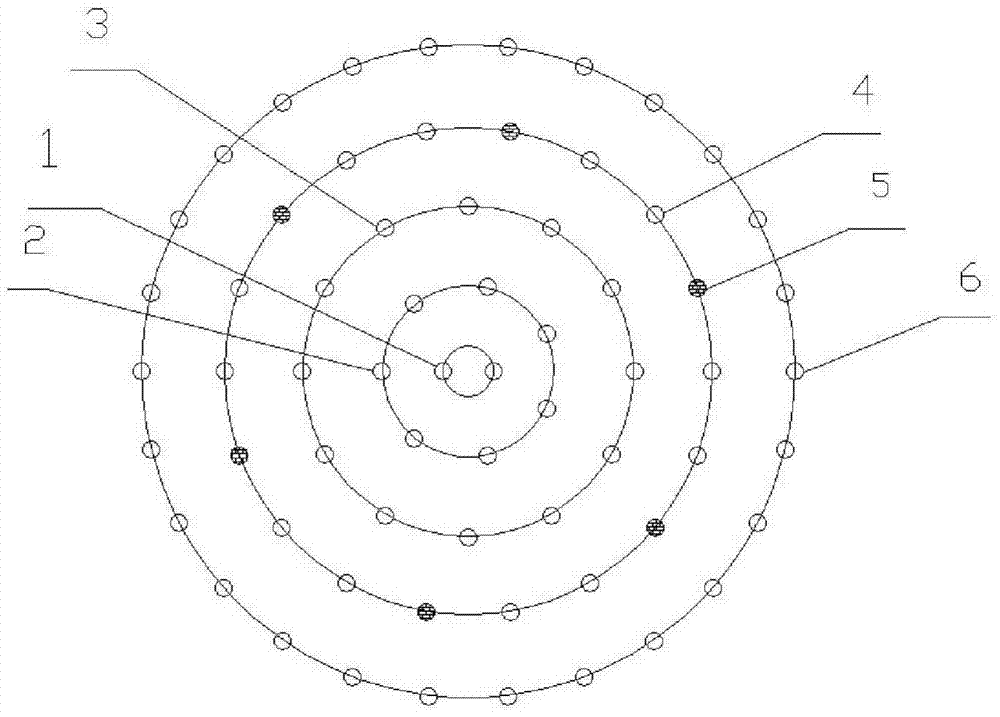

[0016] Taking the center of the wellbore as the center, the order of hole layout from inside to outside is projectile hole 1, cut hole 2, auxiliary hole 3, interval cut holes 4 and 5, and peripheral hole 6.

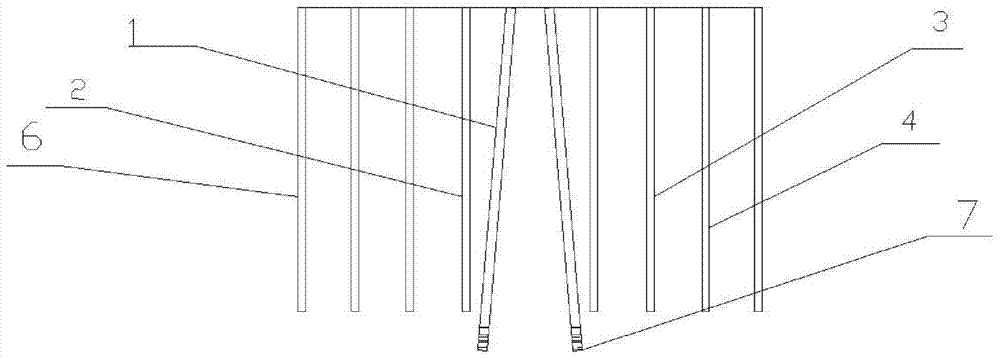

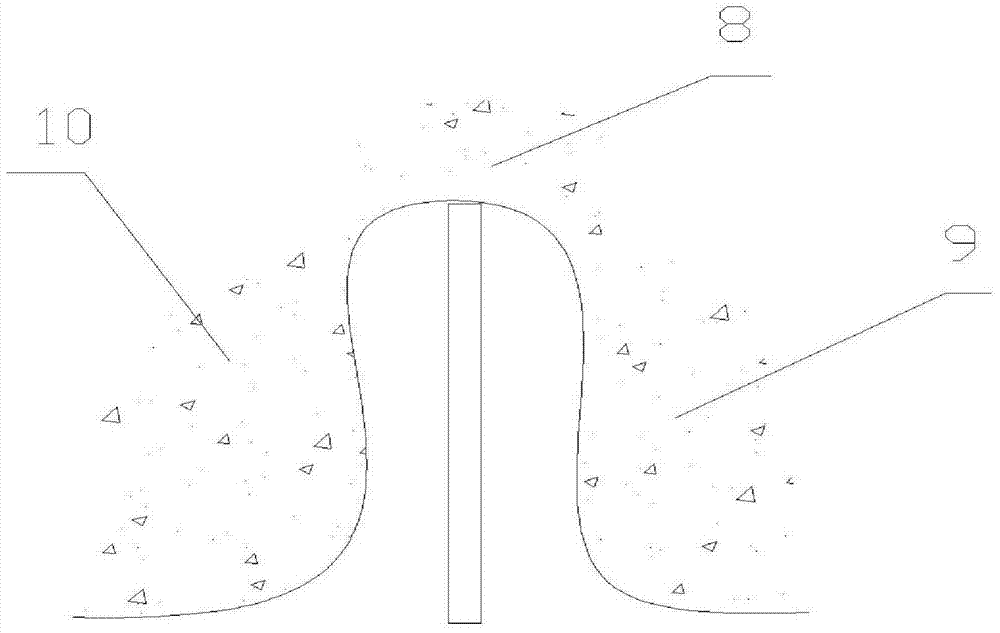

[0017] With the center of the wellbore as the center, a figure-eight projectile hole 1 is arranged on a circle with a circle diameter of 0.2-0.3m, and the oblique insertion angle is 80°-85°. Put 2 volumes of explosives 7 without any filling. When the cutout hole 2 on the side explodes first, the broken body just acts as a filler for the projectile hole 1, and the projectile hole 1 is detonated, which just lifts the broken body and can form a better free surface.

[0018] The ring diameter of the cut hole 2 is 1.4-1.6m larger than that of the projecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com