Blasting vibration predicting method based on particle swarm algorithm optimization support vector machine

A support vector machine and particle swarm algorithm technology, applied in the field of machine learning, can solve problems such as unpredictable vibration intensity, achieve the effect of improving performance, improving prediction accuracy, and expanding the search range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

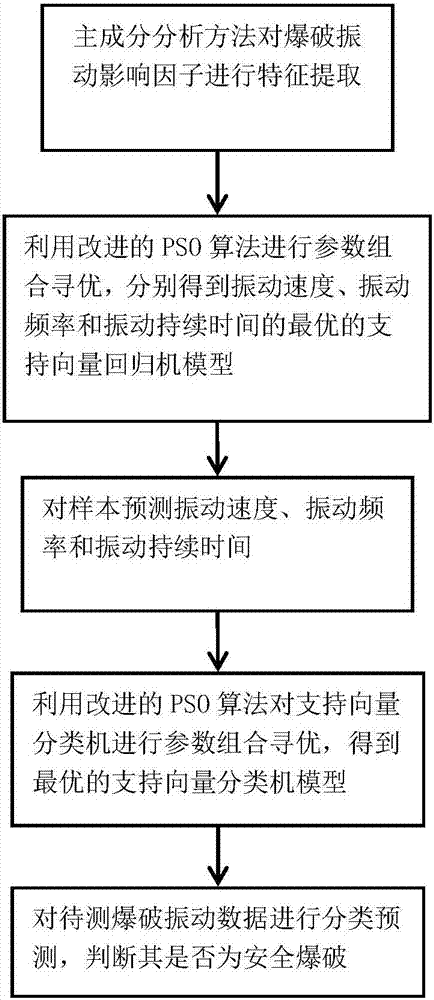

[0033] Such as figure 1 As shown, the blasting vibration prediction method based on particle swarm algorithm optimization support vector machine of the present invention comprises the following steps:

[0034] Step 1: Use the principal component analysis method to extract the features of the impact factors of blasting vibration to obtain a sample data set.

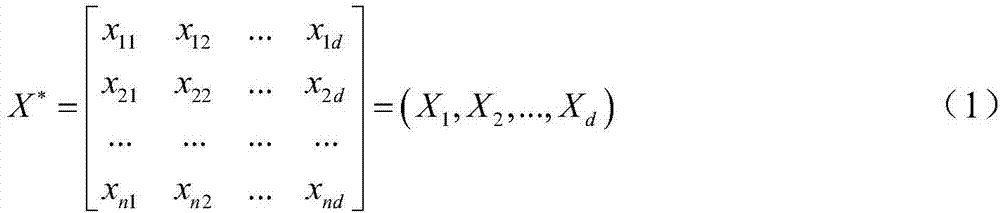

[0035] The original blasting data are a series of parameters that affect the blasting vibration, including aperture parameters, single-stage charge, etc., as well as variables that can be actually measured during the blasting process, such as blasting vibration speed, frequency and vibration duration. It can be used as an important index to evaluate the blasting vibration intensity. In order to obtain the main factors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com