Construction method for damped blasting of tunnels

A construction method and tunnel technology, which are applied in the field of environmental construction and underground excavation of subways, can solve the problems of reducing the blasting vibration velocity, insufficient detonator sections, and small maximum allowable charge in a single section, so as to reduce the blasting vibration velocity and reduce the explosive charge. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

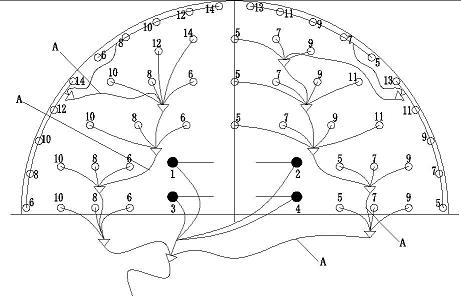

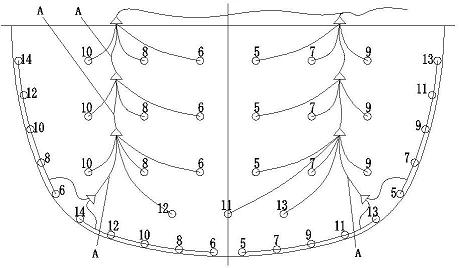

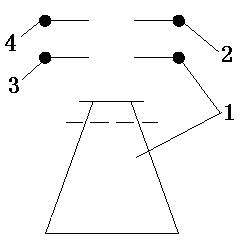

[0018] The tunnel in the first section passes through a large underground shopping corridor. The corridor is a reinforced concrete frame structure with a basement floor and pile foundations under the raft. The tunnel vault is only 4.0m away from the bottom of the pile, and only about 8m away from the bottom of the raft. The specific construction method of shock-absorbing blasting is as follows:

[0019] Adopt YT-28 pneumatic drill to form holes, two pneumatic drills are carried out at the same time, the drilling depth is 1.2m for the cut hole, 1.0m for the auxiliary hole and the surrounding hole;

[0020] The cutting hole adopts four-hole wedge-shaped cutting, the hole spacing is 1.8m, and the hole bottom spacing is 0.5m. When drilling, the angle must be controlled well. If the angle is too large or too small, the cutting effect will be affected;

[0021] Carry out charging in order. The amount of charge for the single hole of the cut hole is 400g, and the charge is concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com