Ultra-close coal layer mining roadway distributing method

A roadway arrangement and extremely close-distance technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems such as waste, achieve the effects of reducing waste rock discharge, saving support costs, and reducing tunneling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following takes a mine as an example to further illustrate the roadway layout method for extremely close-distance coal seam mining.

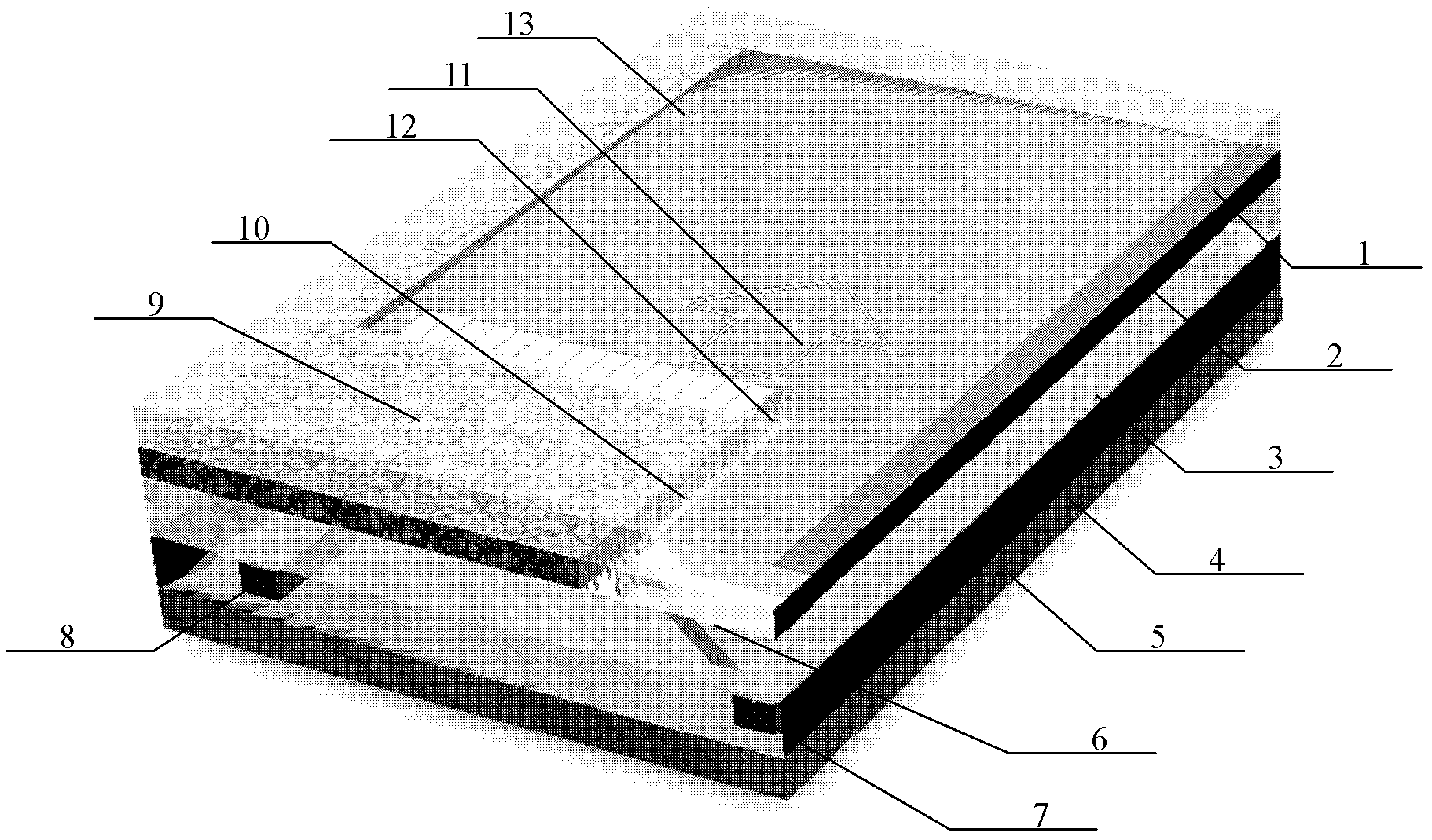

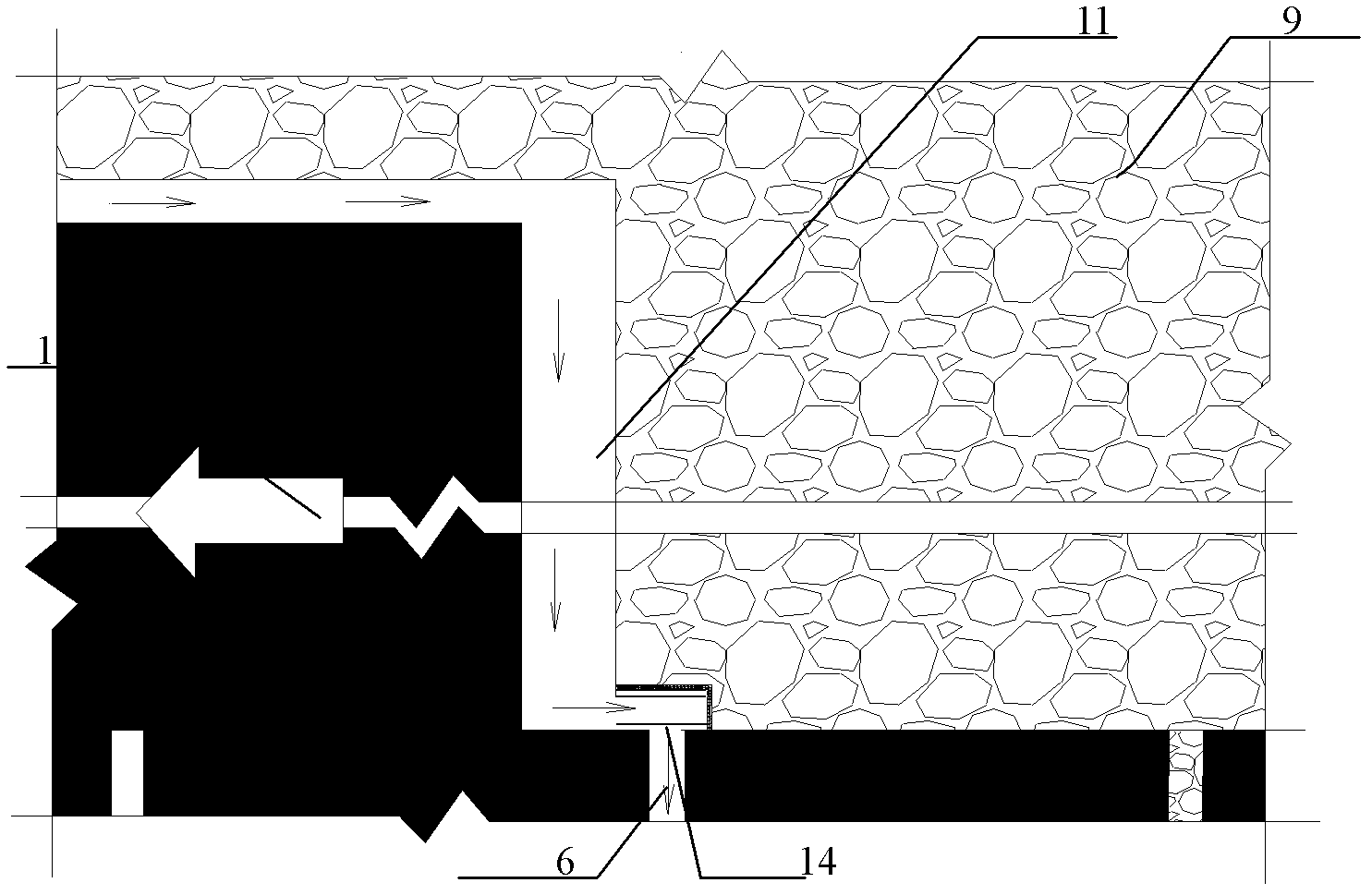

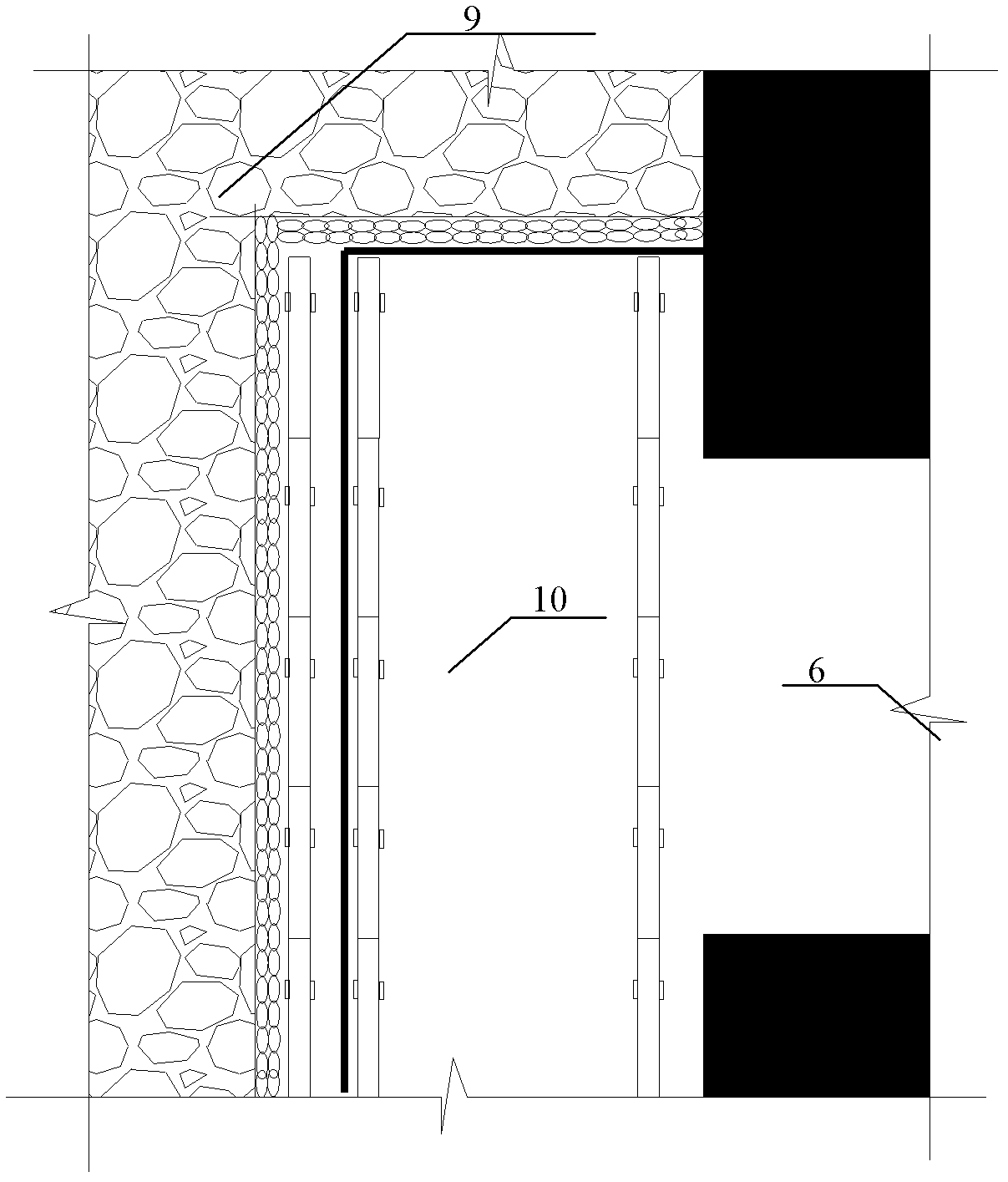

[0022] Such as figure 1 As shown, a certain mine has two coal seams at very close distances, and the coal seam structure is composed of an upper coal seam roof 1, an upper coal seam 2, an upper coal seam floor (also a lower coal seam roof) 3, a lower coal seam 4, and a lower coal seam floor 5. The figure shows the layout of the mining roadway, which is to arrange the lower coal seam transportation roadway 8, the lower coal seam air return roadway 7 and the cutting hole (not marked) in the lower coal seam 4 according to the traditional conventional method; the upper coal seam transportation roadway is arranged in the upper coal seam 2 13 and cut eye; Open up a connection eye 6 connected with the return air lane of lower coal seam 4 at the air return lane position of upper coal seam 2 cut eye, form the primary air return system. Along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com