Method for controlling surrounding rock of roof-cutting self-forming roadway

A control method and roof cutting technology, which is applied in mine roof support, earth square drilling, ground mining, etc., can solve the problems of complicated support work, unclear functions, high support cost, etc., and achieve economical and reasonable control parameters of surrounding rock, The effect of reducing the support cost and the safety and stability of the mining roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

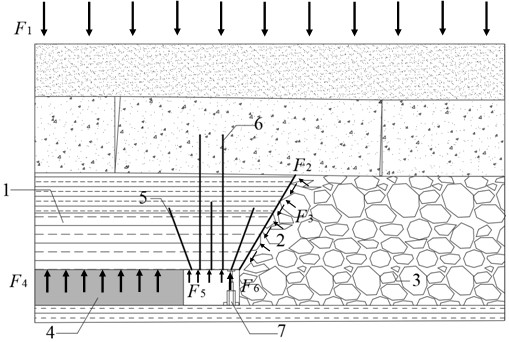

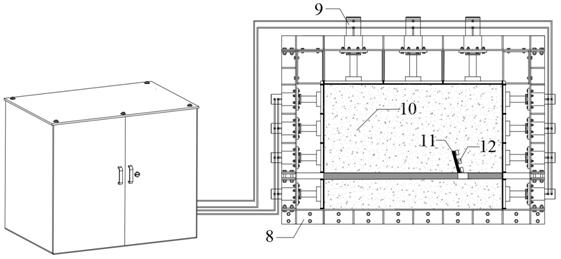

[0031] In a typical embodiment of the present invention, such as Figure 1-Figure 2 As shown in Fig. 1, a method for controlling the surrounding rock of self-formed roadway with cut top is given.

[0032] The support force and load force in the roof cutting area of the roadway form a relative balance, and the support-load balance relationship is established based on the obtained support force and load force.

[0033] Specifically, see figure 1 , through mechanical analysis, a mechanical analysis model of "rock mass fragmentation support-roof support" is proposed, and the model is used to construct the mechanical balance formula of the surrounding rock of the self-forming roadway with cut roof to guide the design of roadway support parameters.

[0034] The mechanical analysis model includes: the load of the overlying rock layer 1 on the roof, the friction force on the roof kerf surface 2 when the overlying rock layer 1 in the goaf collapses by using the mine pressure, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com