Composite supporting method used for ultra-deep comprehensive pipe rack foundation ditch in water crossing riverway

A technology of integrated pipe gallery and composite support, applied in excavation, hydraulic engineering, underwater structures, etc., can solve the problem of large excavation depth of the pipe gallery, and achieve the effect of reducing support costs and reducing machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, a composite support method for foundation grooves of ultra-deep comprehensive pipe galleries in water-passing channels, the steps are as follows:

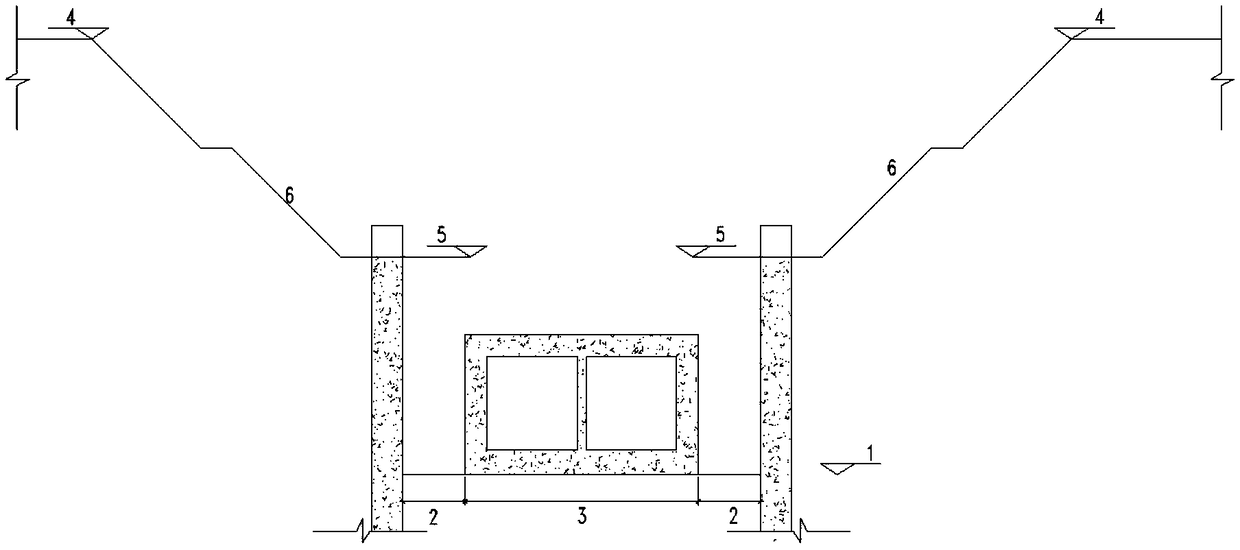

[0033] Firstly, the excavation line of the foundation pit is released on site according to the excavation design drawing of the foundation pit, and the river cofferdam is constructed outside the sliding surface of the foundation pit (the height of the cofferdam must be greater than the maximum water level of the river channel), and the slope slope on both sides of the cofferdam needs to be in accordance with the retaining wall Perform a stability check. Drainage pipes are erected between the upstream and downstream cofferdams, and the drainage pipes are installed with steel pipes. After the upstream and downstream cofferdams and drainage pipes are constructed, the machinery enters the cofferdams for dredging work ( figure 1 Middle 4). Upper foundation pit ( figure 1 Middle 5) Slope excavation is adopte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com