Piston compressor and refrigerant compressor

一种压缩机、制冷剂的技术,应用在机器/发动机、机械设备、液体变容式机械等方向,能够解决压缩机应用性能降低、效率降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

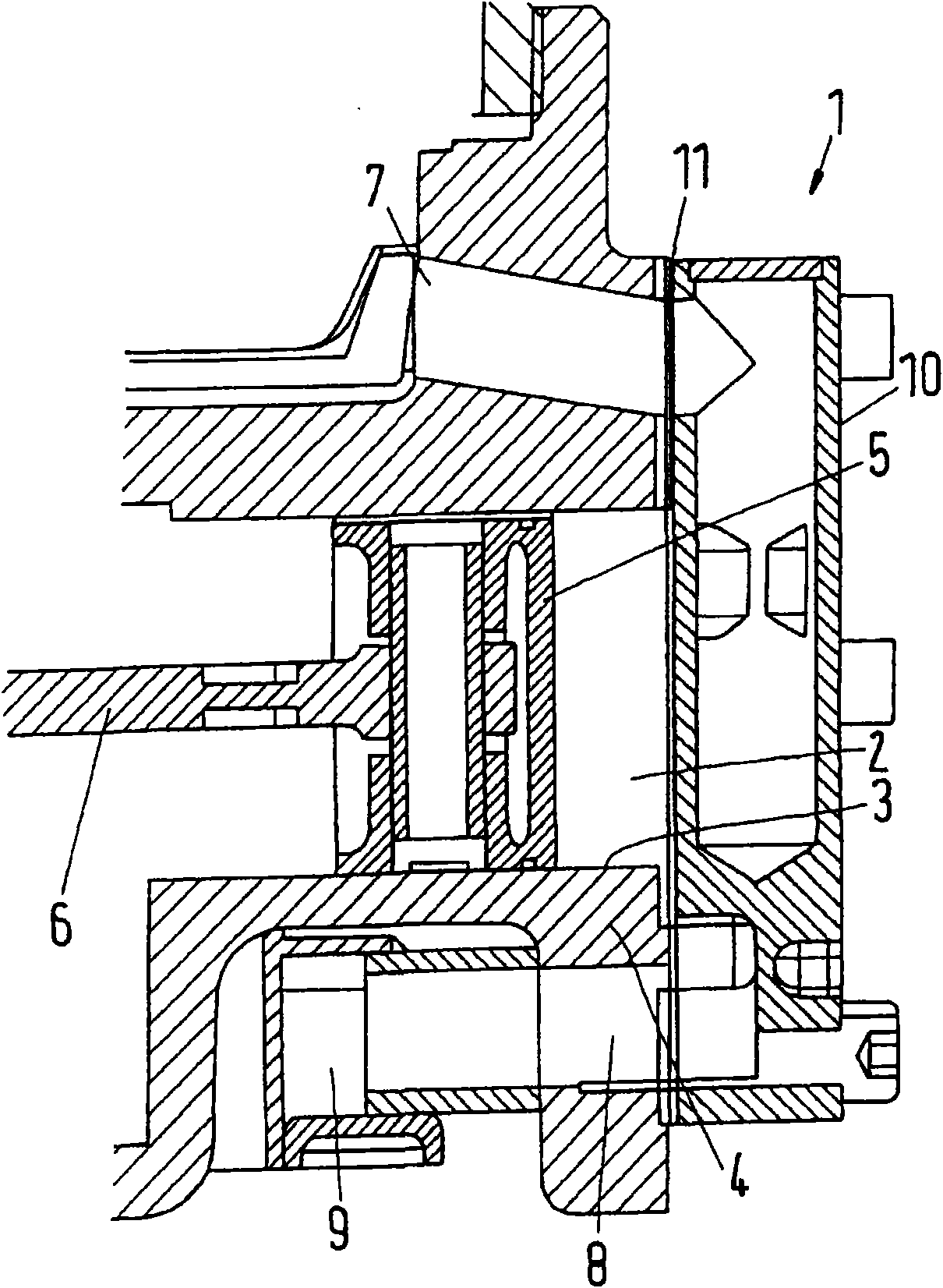

[0021] figure 1 is a schematic diagram of a refrigerant compressor 1 having a compression chamber 2 formed in a cylinder 3 . The cylinder 3 is located in the compressor block 4 . The volume of the compression chamber 2 can be changed by the piston 5, and the driver (not shown in detail) drives the piston 5 to reciprocate through the connecting rod 6.

[0022] The cylinder block 4 is located in a suction passage 7 through which refrigerant gas is sucked into the compression chamber 2 . A compression channel 8 leads partly through the compressor block 4 and supplies compressed refrigerant gas to a compressed gas collection 9 .

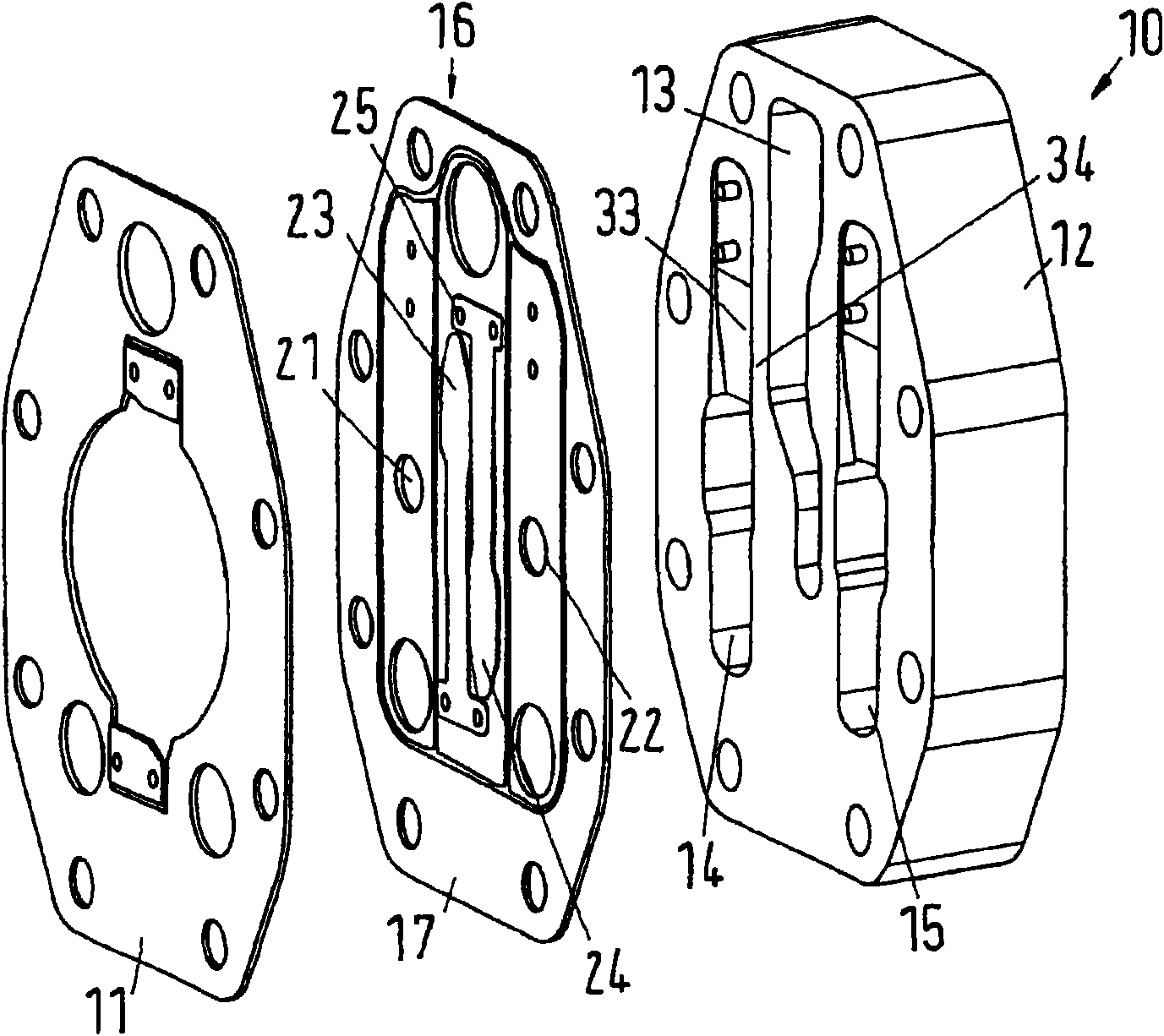

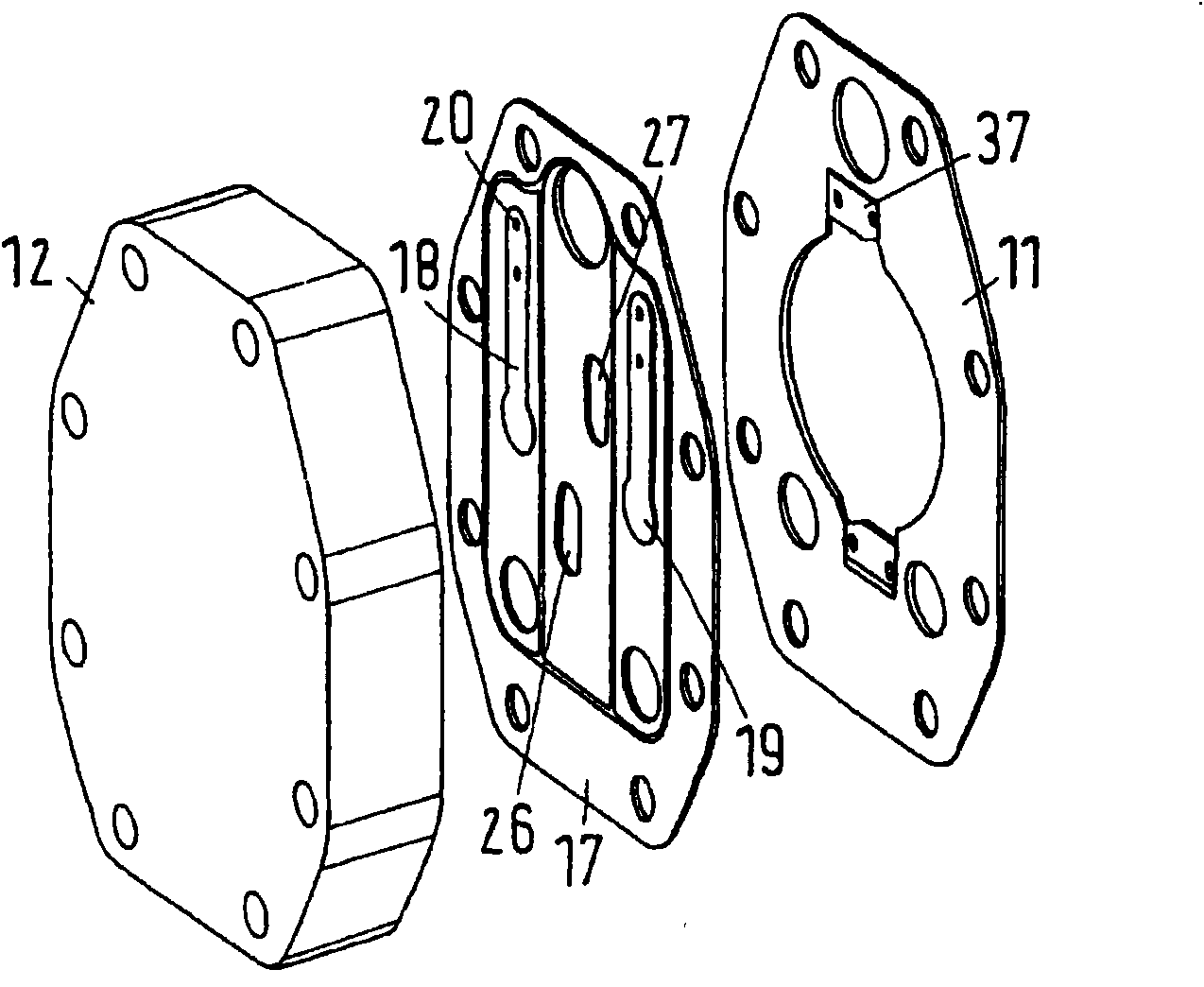

[0023] The cylinder head 10 closes the compression chamber 2 on the front side of the cylinder 3 . The seal 11 is located between the cylinder head 10 and the compressor block 4 . Below, through Figures 2 to 5 The cylinder head 10 is explained in detail.

[0024] The cylinder head 10 has a valve cover 12 in which a suction gas channel 13 and two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com