Preparation method of wear-resistant composite pipe with cast iron/carbon steel honeycomb sandwich structure

A technology of honeycomb sandwich structure and composite pipe, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of low production efficiency, complicated process, and low comprehensive toughness, and achieve high production efficiency, simple operation, and expanded pipe material The effect of specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

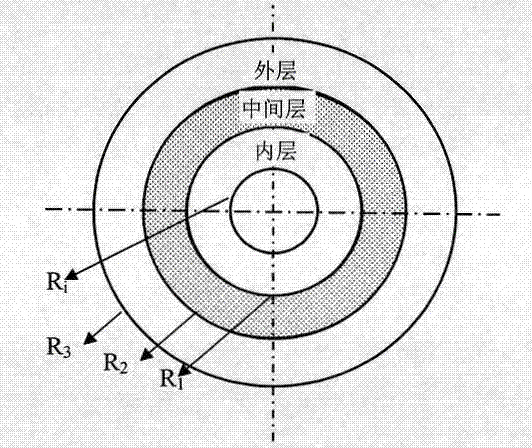

[0030] Three-layer cast iron / carbon steel honeycomb sandwich structure wear-resistant composite pipe composed of ZG270-500 / 18Cr / ZG270-500, the metal thickness ratio of each layer in the finished product is: h 1 : h 2 : h 3 =1:1:1, the outer diameter of the finished composite pipe is Φ650, and the thickness is 20mm.

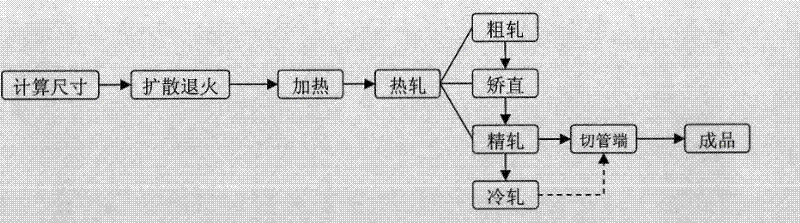

[0031] according to image 3 , the specific production steps are as follows:

[0032] 1) Preparation of cast iron / carbon steel honeycomb sandwich structure centrifugal casting composite tube billet

[0033] according to figure 1 As shown, the Φ800 series centrifugal casting composite tube blank is used, the thickness is 100mm, and the outer radius R 3 800mm, inner diameter R i 732mm, R 1 =672mm,R 2 = 600mm. According to the above dimensions, calculate the required weight of each layer of molten steel and molten iron. According to the requirements of the national standard, molten steel and molten iron of each component are smelted.

[0034] The casting p...

Embodiment 2

[0048] Three-layer cast iron / carbon steel honeycomb sandwich structure wear-resistant composite pipe composed of ZG270-500 / 18Cr / ZG270-500, the metal thickness ratio of each layer in the finished product is: h 1 : h 2 : h 3 =1:1:1, the outer diameter of the finished composite pipe is Φ50, and the thickness is 5mm.

[0049] The specific production steps are as follows:

[0050] 1) Preparation of cast iron / carbon steel honeycomb sandwich structure centrifugal casting composite tube billet

[0051] according to figure 1 As shown, the Φ90 series centrifugal casting composite tube blank is used, the thickness is 25mm, and the outer layer radius is R 3 90mm, inner diameter R i 732mm, R 1 =672mm,R 2 = 40mm. According to the above dimensions, calculate the required weight of each layer of molten steel and molten iron. According to the requirements of the national standard, molten steel and molten iron of each component are smelted.

[0052] The casting process of centrifugal ...

Embodiment 3

[0066] The three-layer cast iron / carbon steel composite pipe composed of 45# steel / 18Cr / 45# steel, the metal thickness ratio of each layer in the finished product is: h 1 :h 2 :h 3 =1:1:1, the outer diameter of the finished composite pipe is Φ100, and the thickness is 4mm.

[0067] The specific production steps are as follows:

[0068] 1) Cast centrifugal billet.

[0069] Using Φ260 series centrifugal casting slab, the thickness is 30mm, the outer radius R 3 130mm, inner diameter R i 100mm, R 1 =120mm, R 2 =113mm. According to the above dimensions, calculate the required weight of each layer of molten steel and molten iron. According to the requirements of the national standard, molten steel and molten iron of each component are smelted.

[0070] The casting process of the composite tube blank is as follows: first cast the 45# steel layer, the pouring temperature is 1540 ℃ ~ 1590 ℃, the degree of superheat is 40 ℃ ~ 90 ℃, and the centrifuge speed is 400 ~ 600 rpm. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com