Short stage preparation method of multi-layer metal composite plate

A multi-layer metal and composite plate technology, applied in metal rolling and other directions, can solve the problems of shortened production process, low bonding strength, complex process, etc., and achieves the effect of excellent comprehensive mechanical properties, simple operation and simplified production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The outer and inner layers are 2Cr13, the middle layer is a three-layer metal composite plate of 9Cr18MoV, the metal thickness ratio of each layer in the finished product is: h1:h2:h3=2:1:2, hot-rolled plate H=3mm, cold Rolled plate H=0.2mm.

[0037] The specific production steps are as follows:

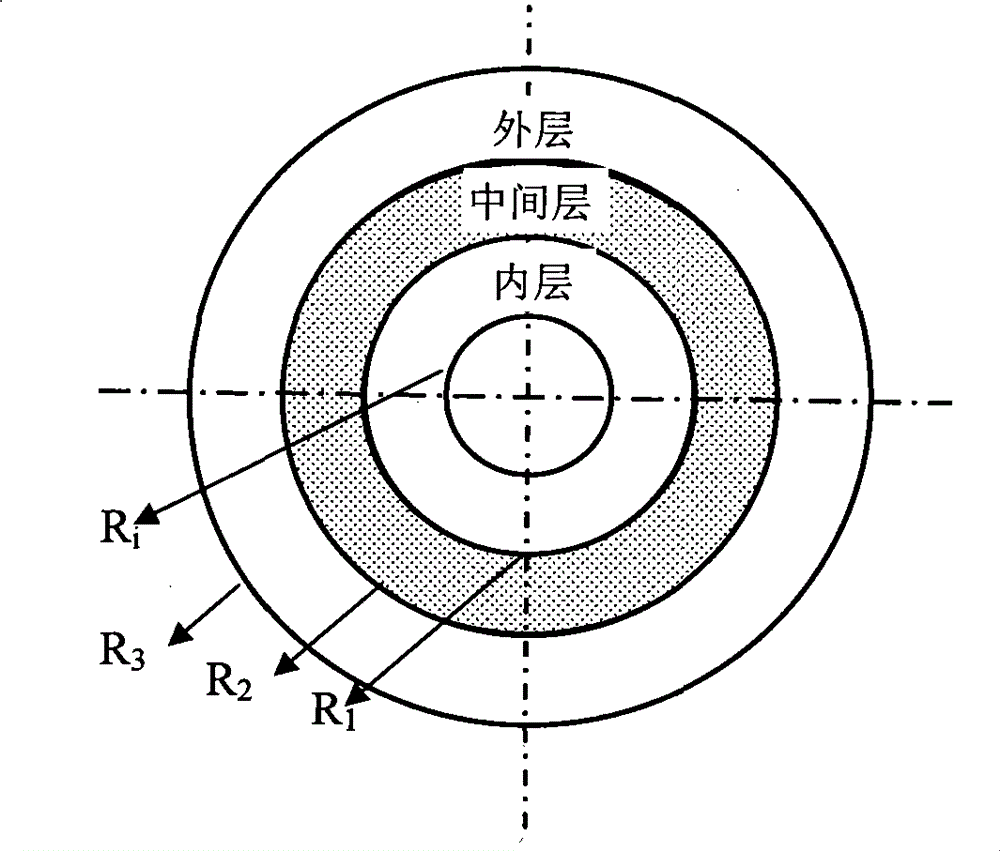

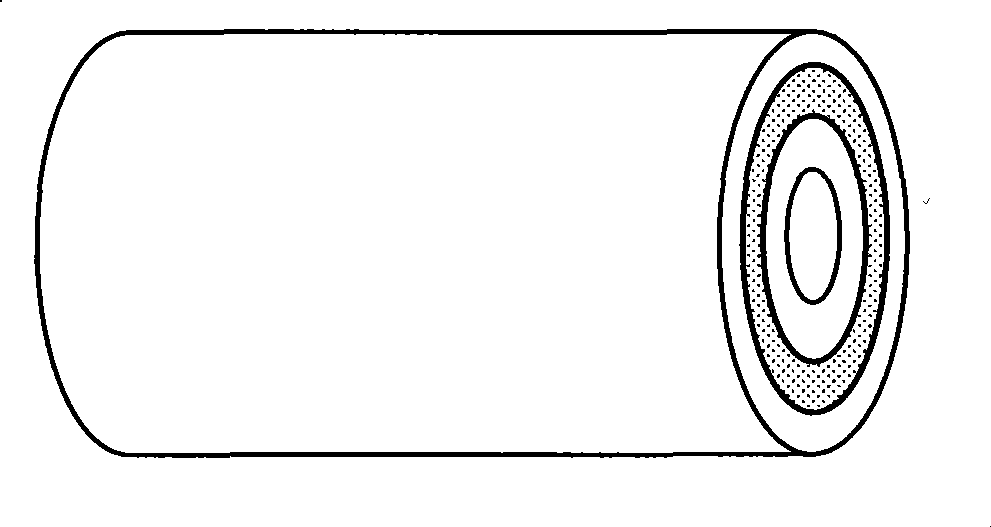

[0038] 1) Choose centrifugal casting composite tube blank. The inner and outer layers of the composite tube blank are 2Cr13, and the middle layer is 9Cr18MoV. Using Φ700 series centrifugal casting slab, the outer radius R 3 350mm, inner diameter R i is 250mm. According to formula (1), it can be obtained that R 1 =313.8mm, R 2=294.1mm, the thickness of the composite tube blank is 100mm. According to these composition and size requirements, the corresponding tube blank can be selected.

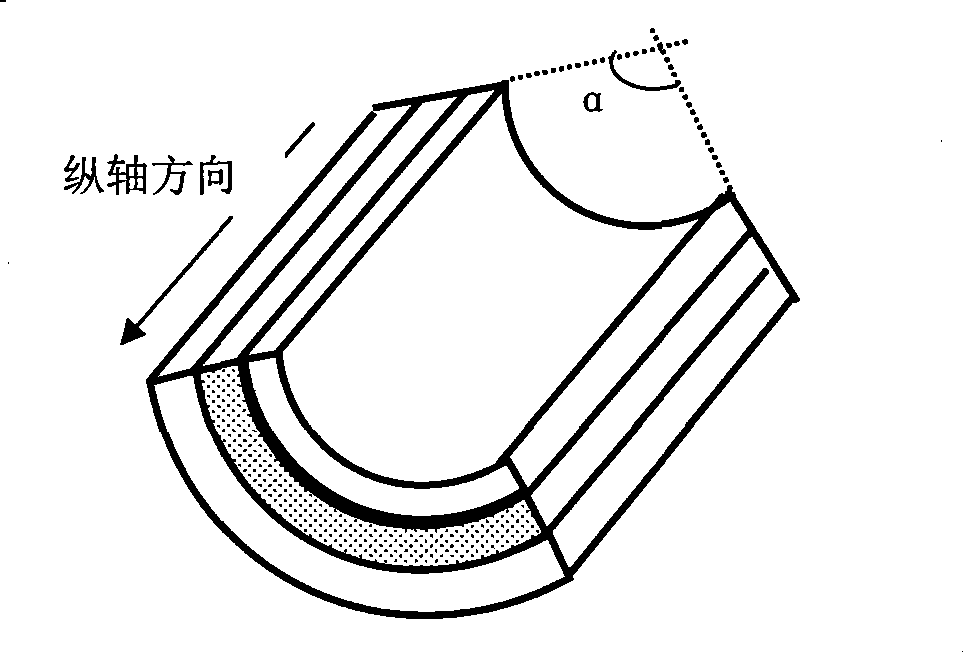

[0039] 2) The composite tube blank is divided into three parts along its axial direction, and the central angle α of each part is about 120° (it can also be divided into 4 parts, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com