Large plate bottom supporting method for soft rock roadway

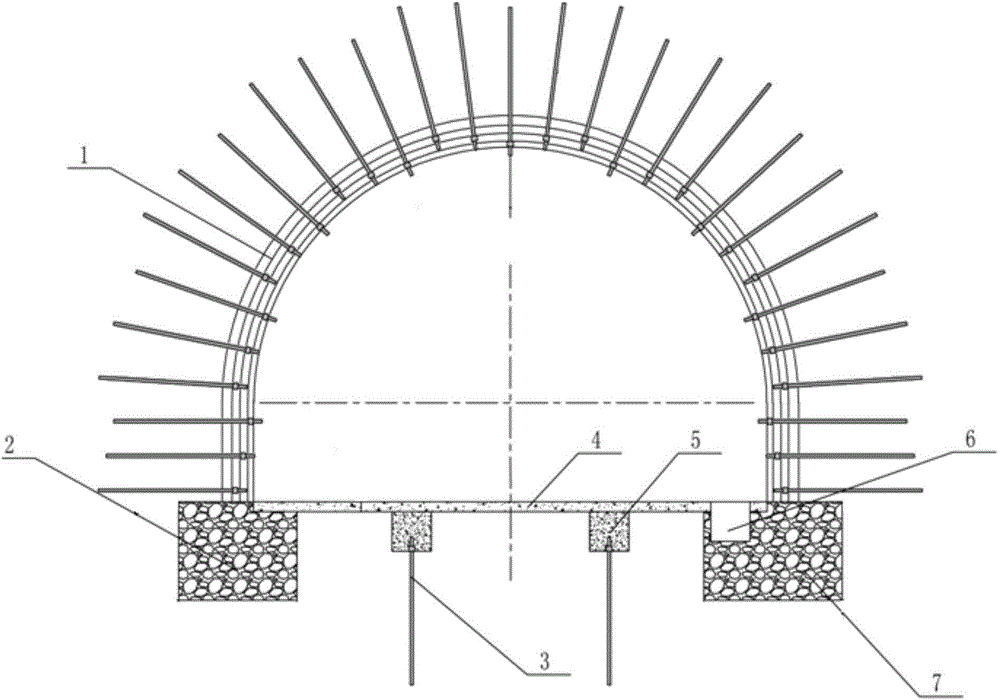

A roadway and slab technology, applied in the field of large slab bottom support for soft rock roadways, can solve the problems of difficulty in ensuring the stability of the roadway, bulging of the floor and two gangs, and collapse of the roadway.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0012] In the embodiment, the present invention considers that the strength of the surrounding rock of the roadway under various complex stresses and the state of crossing the fault fracture zone is low, the flow of the surrounding rock on the floor of the soft rock roadway is strong, the mud of the floor is serious, and the bearing capacity of the surrounding rock in the shallow part of the roadway is low , especially due to the horizontal stress of the surrounding rock, the shear stress of the two shoulders and the two bottom corners is concentrated, and the bottom corner is seriously damaged to form a low shear stress zone, which results in the restrained variation of the two sides and the serious bulging of the bottom plate. To this end, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com