Method for solving gas choking of coupler knuckle

A knuckle and core technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems such as threats to the safety of railway vehicles, economic losses for manufacturers, and increased gas production, so as to avoid increased gas production, Improved process yield and reduced metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

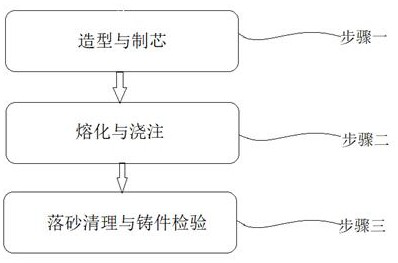

[0018] Shown in the accompanying drawings below, the present invention is further described: the present invention is a method for solving hook tongue choking, including:

[0019] Step 1, molding and core-making: the knuckle is provided with at least one internal core, and the raw materials of the core are raw sand for 650 resin sand and 650 resin, and the composition of the raw sand for 650 resin sand: SiO2≥98%, moisture content ≤0.5%, mud content ≤0.5%, fine powder content ≤1%, particle size 50 / 100≥80%, temperature 15°C-30°C;

[0020] The added amount of the 650 resin accounts for 3.0%-4.5% of the total amount of raw materials;

[0021] The core cannot be used immediately, the finished core must be placed in a ventilated and dry place for a period of time;

[0022] Step 2, melting and pouring: bake the core when closing the box, the baking temperature is controlled at 90°C-120°C, the raw sand for 650 resin sand is pyrolyzed at high temperature, thereby forming bright carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com