Mining roadway gob-side entry retaining method suitable for thin and medium thickness coal seams

A technology for mining roadways and thick coal seams, which is applied to mining equipment, earthwork drilling, and fillings, etc. It can solve problems such as poor isolation of gobs, mismatched shrinkable performance, and insufficient support resistance, etc., to reduce roadway support. The effects of reducing maintenance costs, improving coal recovery rate, and reducing coal pillar loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

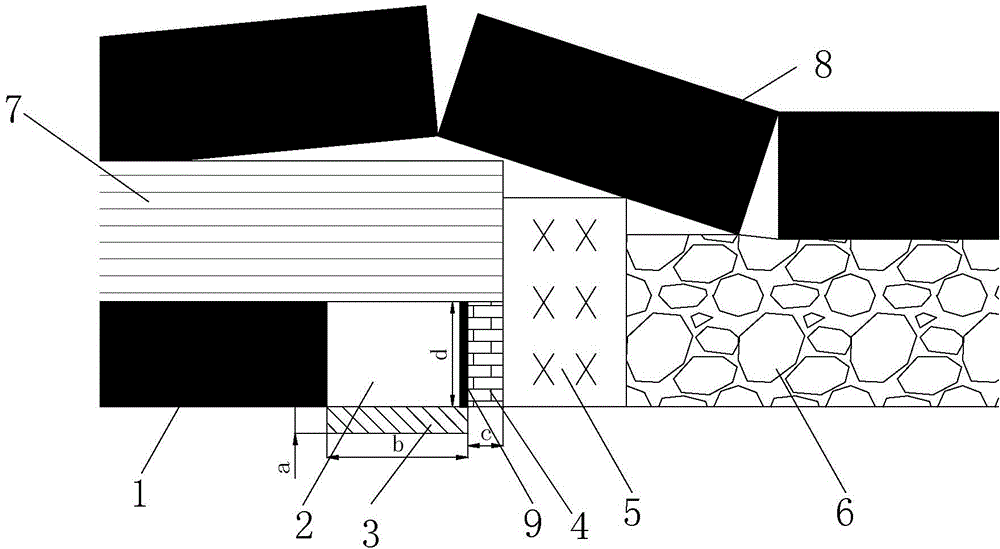

[0017] Such as figure 1 As shown, the method for retaining roadway along the goaf of the mining roadway provided by the invention comprises the following steps:

[0018] 1) Using the floor rock 3 obtained undercover in the mining roadway 2 as raw material, with appropriate cement as the cement, build a flexible isolation body 4 next to the roadway near the goaf 6 side.

[0019] 2) Drill energy-concentrating blast holes on the hard old roof above the goaf 6. The blast holes are located outside the isolation body 4, and the roof on the side of the gob 6 is blasted and cut down so that the overlying rock layer 8 forms a "masonry beam". "structure.

[0020] 3) After the separator 4 and the cut-off top plate 5 are stabilized, a layer of foaming agent 9 is sprayed on the surface of the separator 4 .

[0021] In a preferred embodiment, the undercover leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com