Steel concrete reinforced prefabricated energy-saving residential building system

A concrete and prefabricated technology, which is applied in the direction of architecture, building components, building structures, etc., can solve the problems of complex production process of prefabricated prefabricated concrete, difficulty of on-site assembly and construction, and late start of maintenance structure, so as to solve fire prevention and anticorrosion problems, remarkable energy-saving effect, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

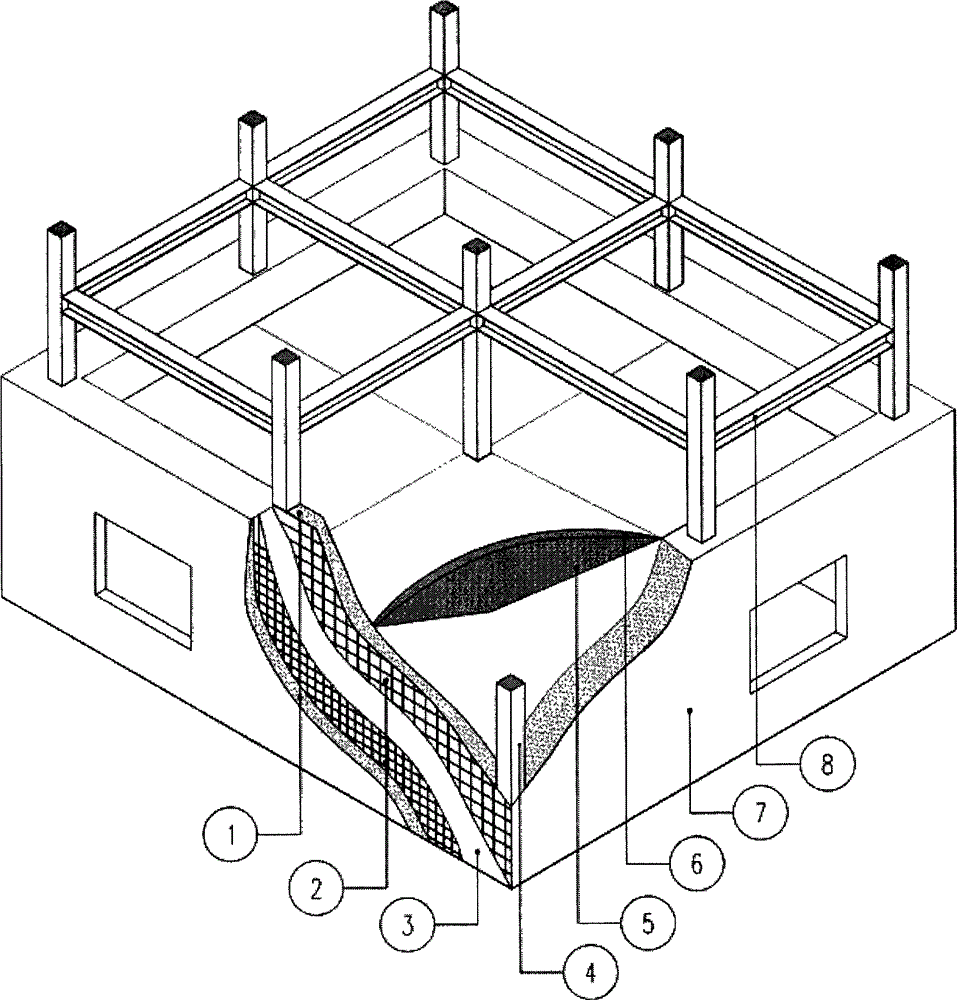

[0014] The present invention will be further described below in conjunction with accompanying drawing 1.

[0015] See Figure 1, in which 1 is cast-in-place concrete, 2 is the steel mesh of CL truss slab, 3 is polystyrene slab of CL truss slab, 4 is steel pipe concrete column with concrete poured inside, 5 is truss floor deck, 6 is The cast-in-place concrete floor, 7 is the CL exterior wall, and 8 is the H-shaped steel beam.

[0016] Fix the square steel pipe column 4 on the foundation of the residential building, install H-shaped steel beams 8 on the joints of each floor of the square steel pipe column 4, and the square steel pipe column 4 is divided into one section every three floors. After all the installation is completed, it will form the main body of the residential building frame. Install the column inner side formwork on the inner side of the square steel pipe column 4 on the first floor of the residential building; install the CL truss plate composed of 2 and 3 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com