A layering and partially filling coal mining method of thick seams

A thick coal seam, layered mining technology, applied in filling, ground mining, mining equipment and other directions, can solve problems such as resource loss, and achieve the effects of reducing filling cost, high coal recovery rate, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

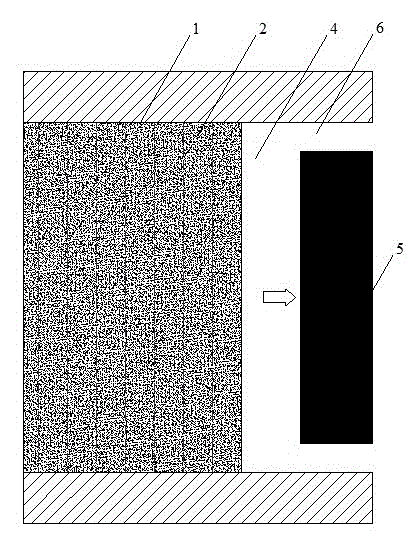

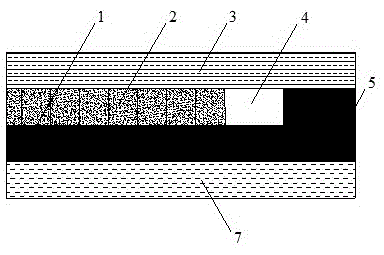

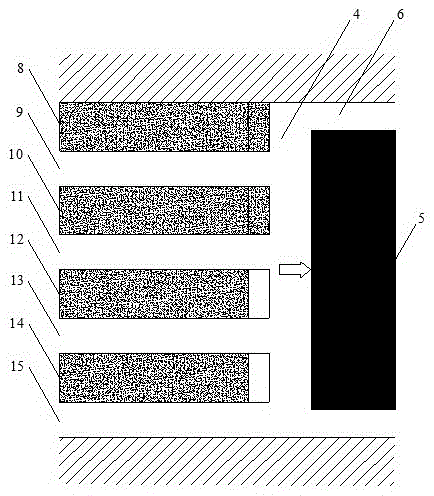

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] The thick coal seam layered partial filling coal mining method of the present invention, its coal mining step is as follows:

[0022] a. To extract the geological conditions of the coal seam, according to the range and protection level of the surface building groups, and based on the determination of the traditional mining area range, the surface building groups are within the protection range of the filling zone, and the "buildings, water bodies, railways and major The protection level requirements of the Coal Pillar Retention and Pressure Coal Mining Regulations in Shaft Roadway are used as the standard to determine the coal filling and mining range under the mine; b. According to the thickness of the coal seam, the coal seam 5 is divided into upper and lower layers, and the top of the coal seam 5 is the roof 3, The bottom is the bottom p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com