Equipment and method for filling hard cartons with cigarette packets

A technology of rigid strips and boxes, applied in packaging and other directions, can solve the problems of easy damage to the surface of cigarette packs, no sulfuric acid paper, etc., and achieve the effects of reducing filling costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] Embodiment 2, the filling method of the present invention, comprises the steps:

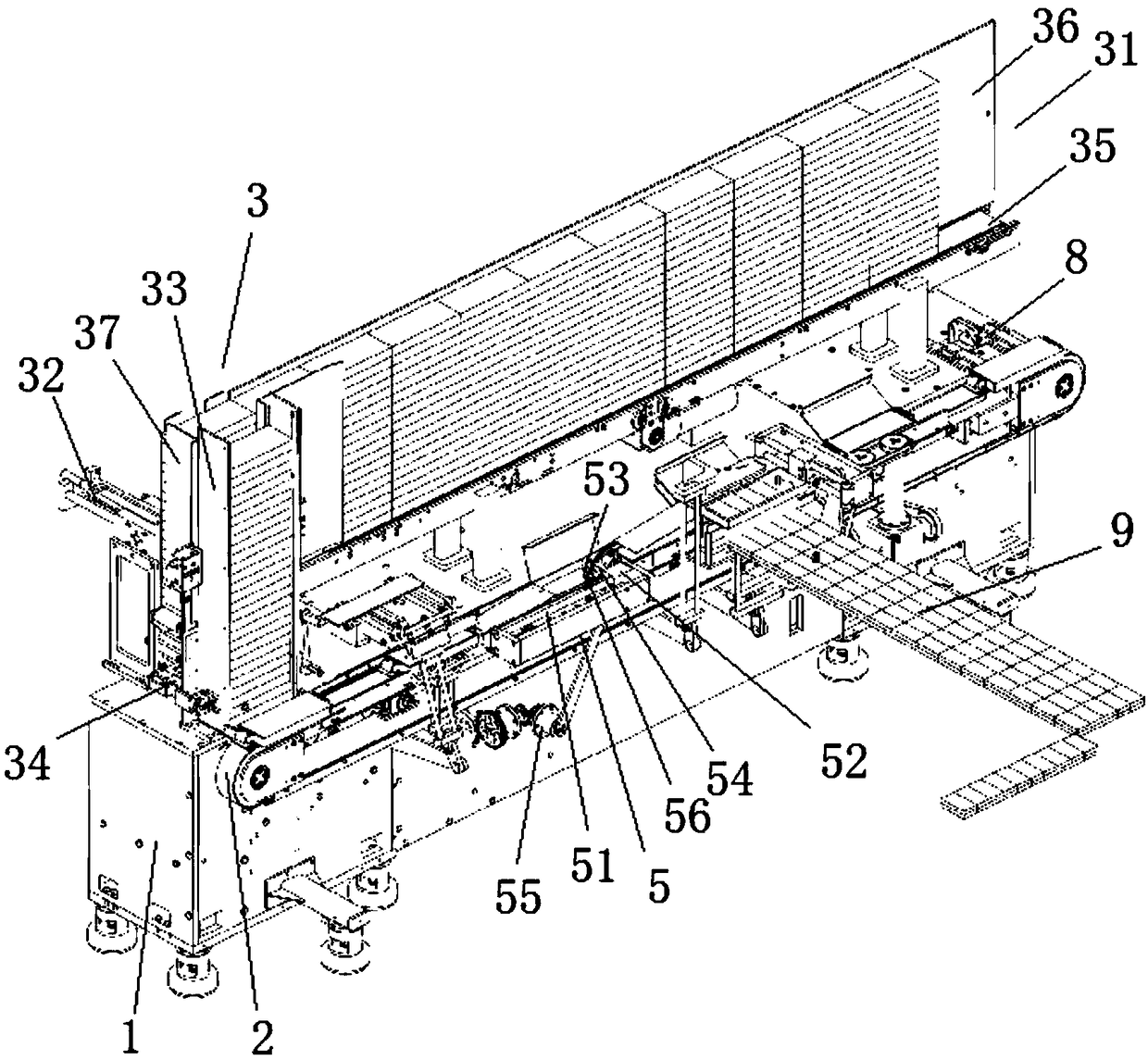

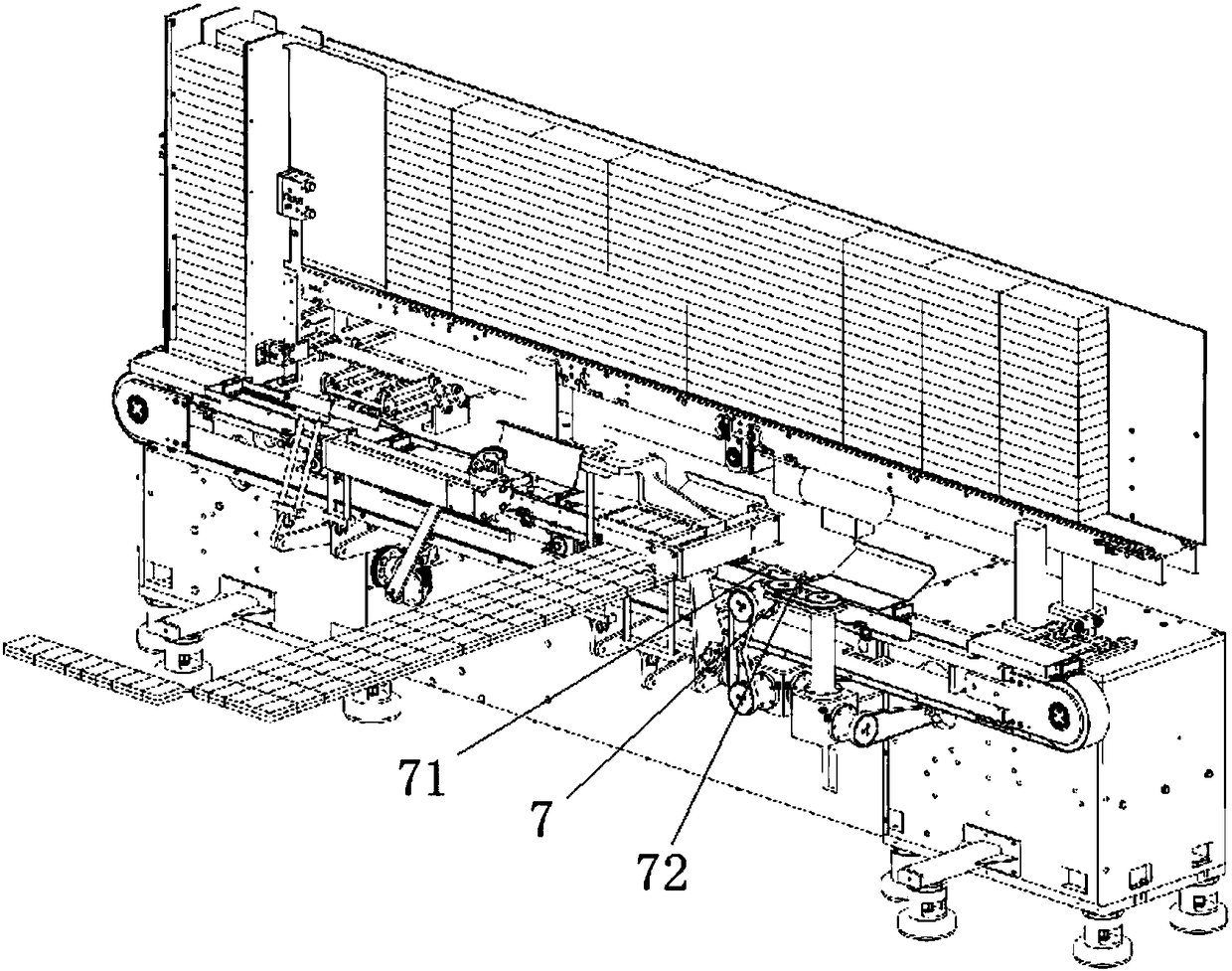

[0041] In the first step, the barrel conveyor belt 2 is intermittently moving, and when the barrel conveyor belt 2 stops, the barrel pushing device 34 pushes a barrel in the barrel stack 33 into the barrel. In the mold box of the carton conveyor belt 2, after the number of cartons in the carton stacker 33 is reduced by a corresponding amount, the pushing carton stacker 32 will push the cartons in the carton storage 31 The stack is pushed into the barrel stack warehouse 33, and the barrel boxes at the rear of the barrel storage warehouse 31 are moved forward by the conveyor belt 35;

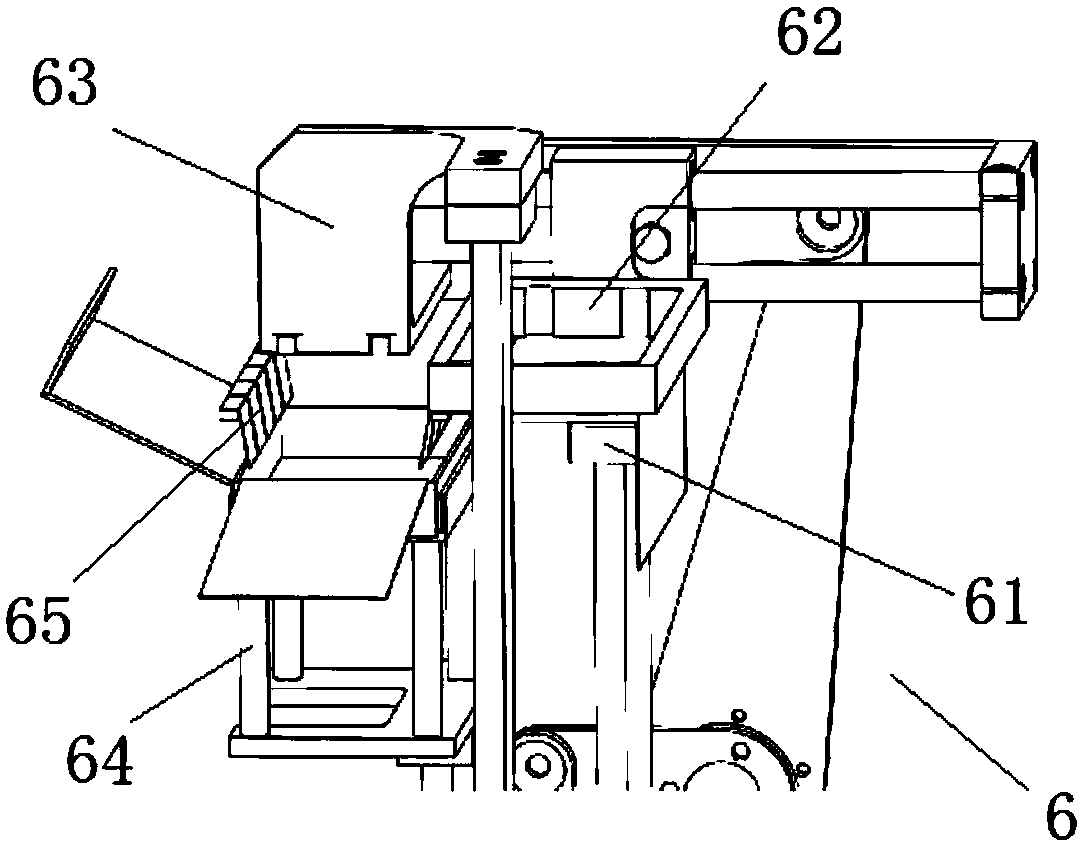

[0042] In the second step, when the barrel moves to the position of the cover opening mechanism 4, the box body of the barrel is moved upwards by the second suction nozzle 42 arranged below the barrel, and at the same time, the barrel body is sucked by being arranged on the barrel The first air suction nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com