Halon fire extinguisher filling process control equipment and method for filling process control

A process control, fire extinguishing bottle technology, applied in the direction of using back pressure perfusion, liquid filling, etc., can solve problems that restrict the further improvement of the maintenance and support capabilities of weapons and equipment, lack of high-efficiency maintenance and support equipment, and affect the fire-extinguishing (explosion suppression) system of weapons and equipment Maintenance support and other issues, to achieve the effect of supporting equipment supporting construction, high degree of automation, and improving support capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

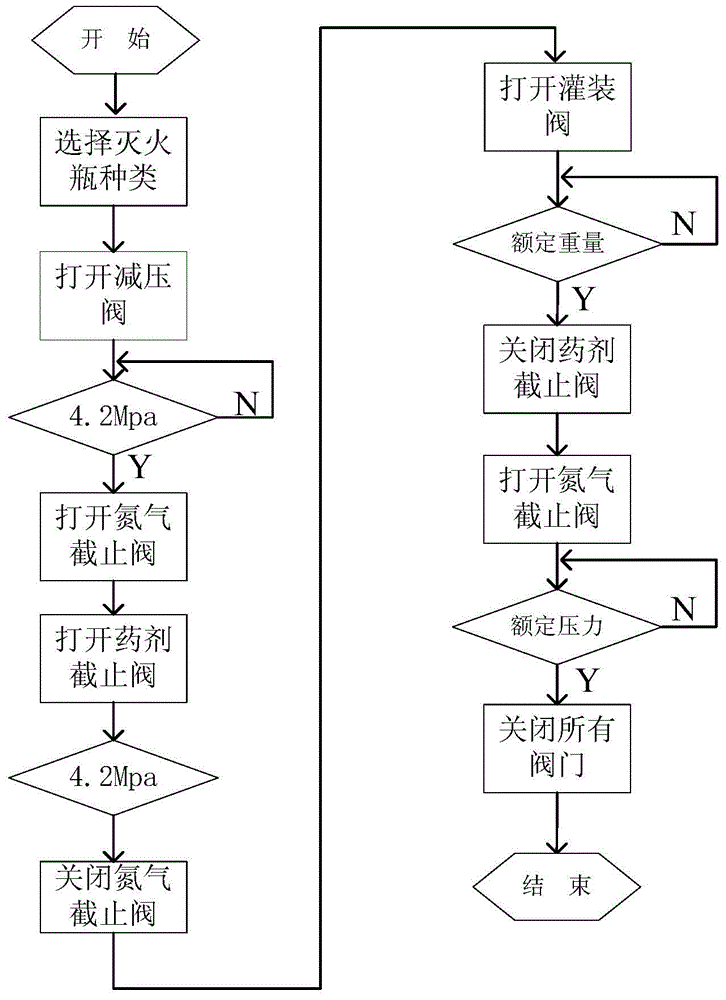

[0015] The present invention will be described in detail below with reference to the accompanying drawings.

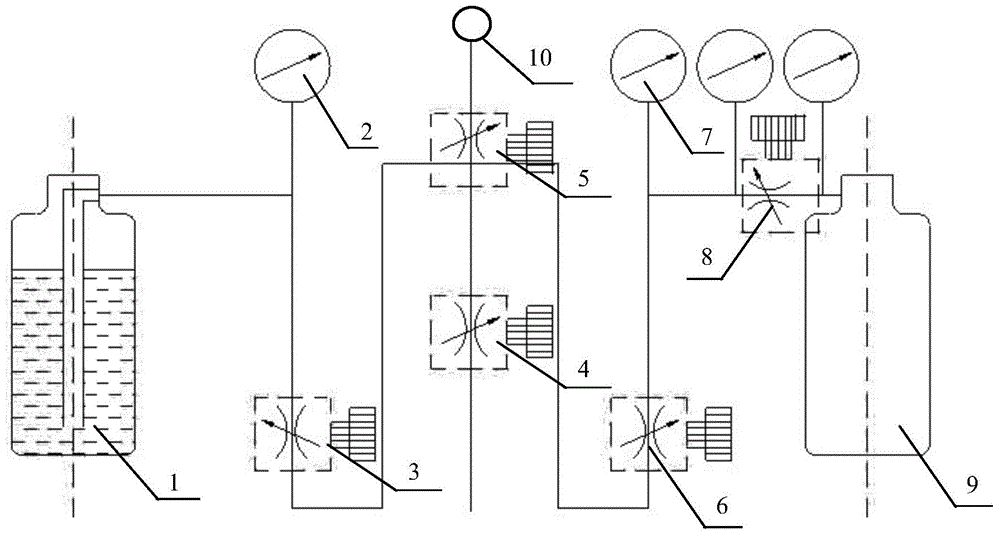

[0016] refer to figure 1 , the outlet of the nitrogen cylinder is connected to the pressure reducing valve 8 of the nitrogen cylinder, the outlet of the pressure reducing valve is connected to three links and one, and the three links and one tap are connected to the nitrogen pressure gauge 7, the nitrogen shut-off valve 6, the nitrogen shut-off valve is connected to the deflation valve 5 and the filling valve 4, The air release valve is connected with the air release port 10; the three-way two-way tap is connected to the liquid medicine bottle 1, the liquid medicine pressure gauge 2, the liquid medicine shut-off valve 3, and the liquid medicine shut-off valve 3 is connected to the air release valve 5.

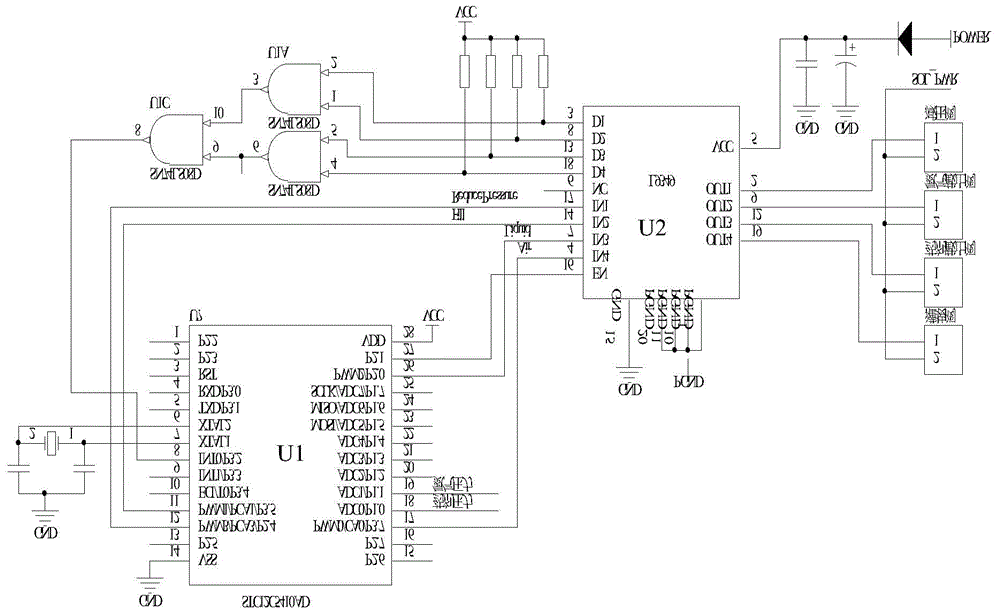

[0017] refer to figure 2 , the single-chip microcomputer U1STC12C5410AD generates four channels of PWM waveforms with different duty ratios, and controls the dedicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com