Anti-explosion servo weight control system and weight control method thereof

A technology of servo motors and explosion-proof housings, applied in the field of volume control systems, can solve the problems of being unable to meet high-precision and high-speed filling requirements at the same time, reduce the risk of intelligent automatic filling operations, and avoid the problem of material leakage , Provide the effect of filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

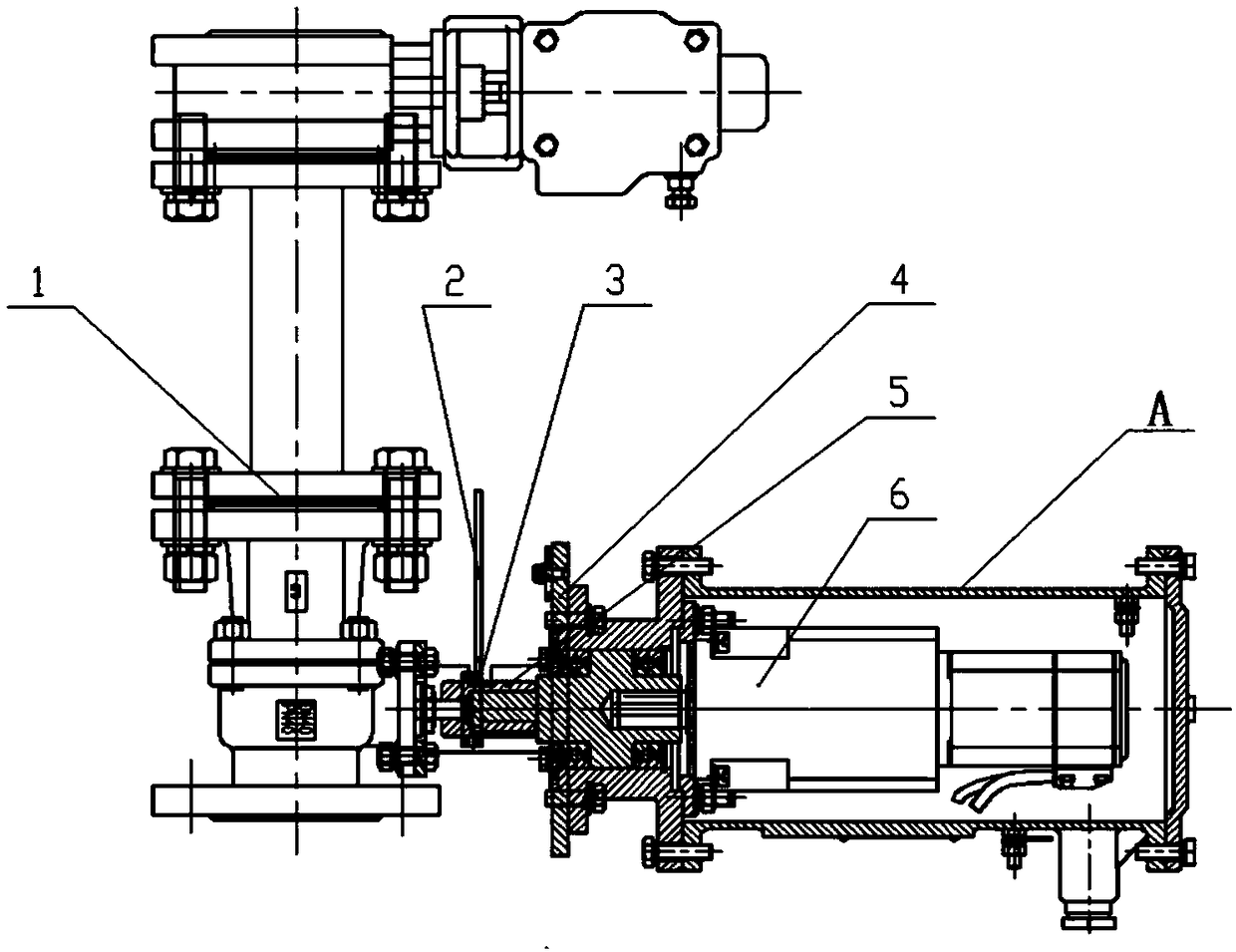

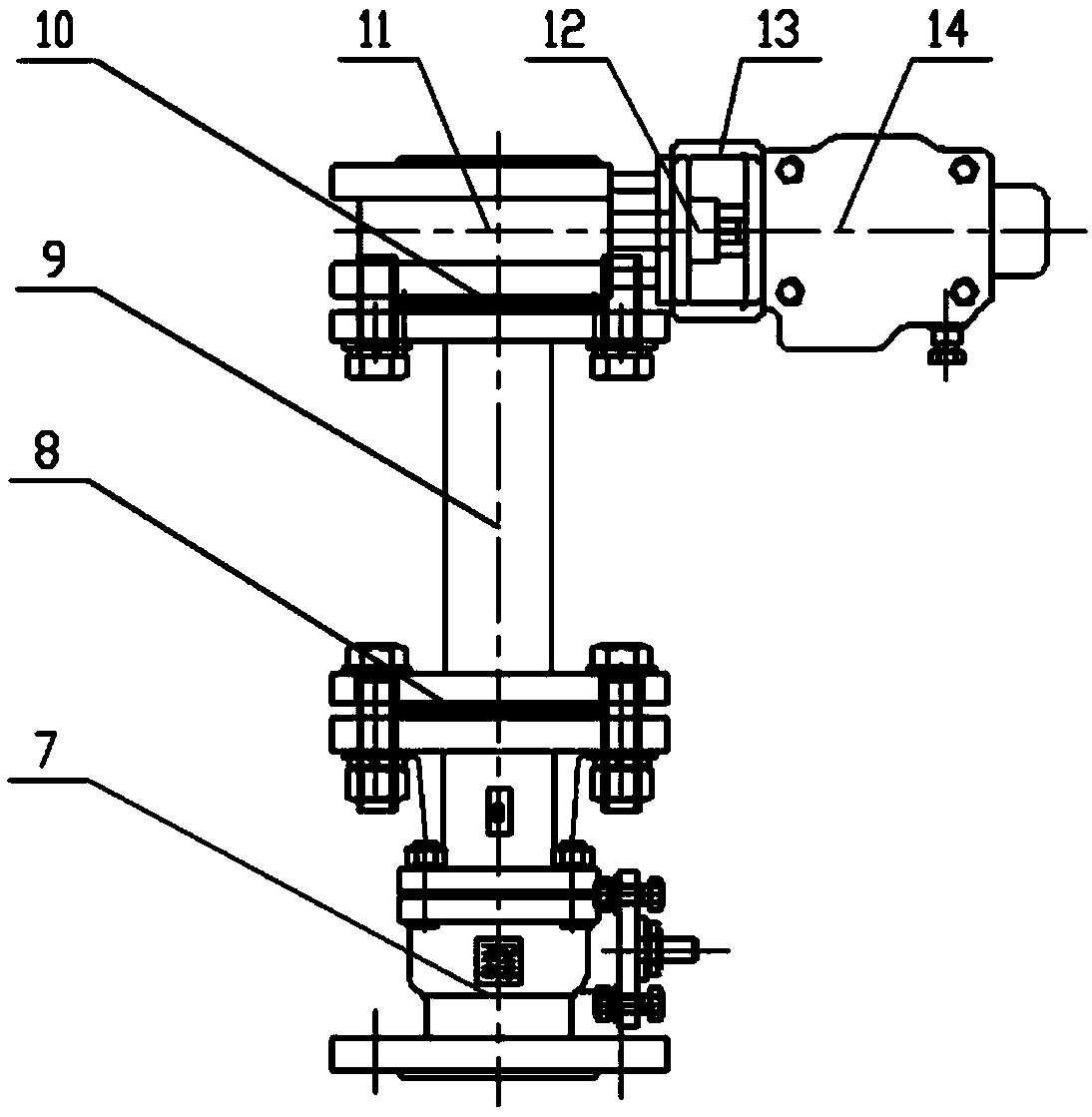

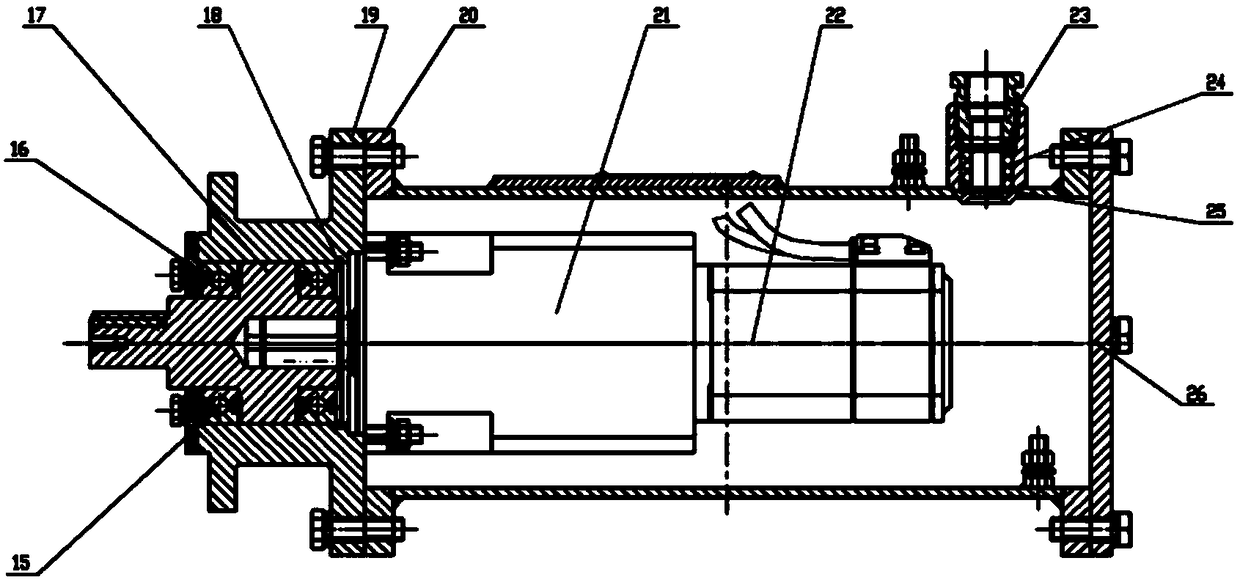

[0029] Embodiment 1 An explosion-proof servo volume control system

[0030] refer to figure 1 , the explosion-proof servo volume control system provided by the present invention includes: a volume control body 1 and an explosion-proof execution unit 6; the volume control body 1 and the explosion-proof execution unit 6 are connected by bolts through a connecting bracket 4 to form a whole; The rotating shaft of the volume control body 1 is connected with the power output shaft of the explosion-proof execution unit 6 through the connection shaft 5, and the state of the volume control ball valve on the volume control body 1 is controlled by the explosion-proof execution unit 6. During the specific installation process, the connection shaft 5 and the The power output shaft of the explosion-proof execution unit 6 is connected by a flat key; and in order to prevent the connection failure of the connecting shaft 5, a fastening ring 3 is preferably provided on the connecting shaft 5, a...

Embodiment 2

[0039] Embodiment 2 Volume control method of explosion-proof servo volume control system

[0040] In order to make those skilled in the art more aware of the specific volume control method of the volume control system provided in Example 1, the following takes a filling weight of 200 kg as an example, and assumes that the volume control ball valve rotates 90° to be fully open, and introduces the control system of the present invention in detail. The specific steps of the measurement method.

[0041] A volume control method for an explosion-proof servo volume control system, the method specifically includes the following steps:

[0042] Step S1, connect the cable of the servo motor 22 to the external power supply, start the servo motor 22, the servo motor acts, and at the same time drives the planetary reducer 21 to move, the planetary reducer drives the shaft joint 17 to rotate, and rotates the rotating shaft of the control ball valve 7 by a certain angle ( 60°), so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com