A kind of bubble water toy automatic production line and its production method

An automatic production method and automatic production line technology, applied in toys, mechanical conveyors, transportation and packaging, etc., can solve the problems of low production efficiency of manual filling of bubble blowing sticks, and achieve improved production stability, stable performance and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

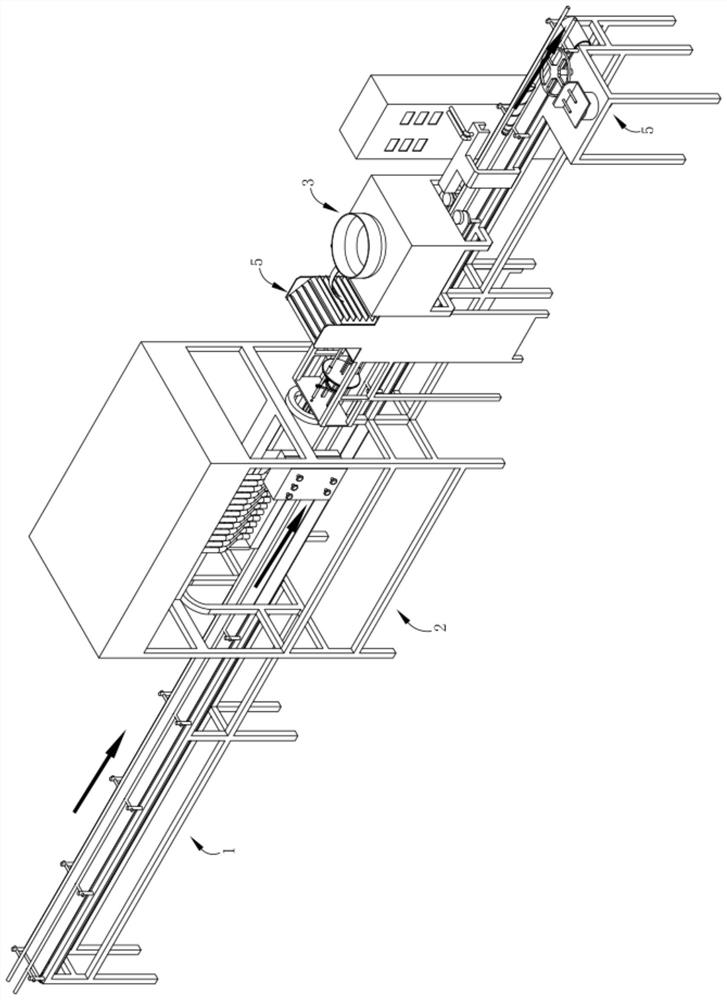

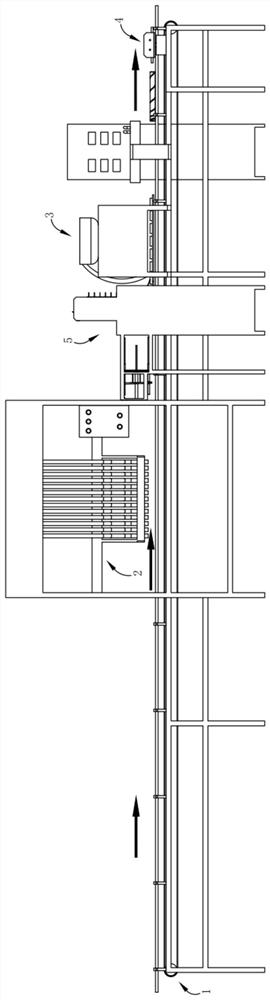

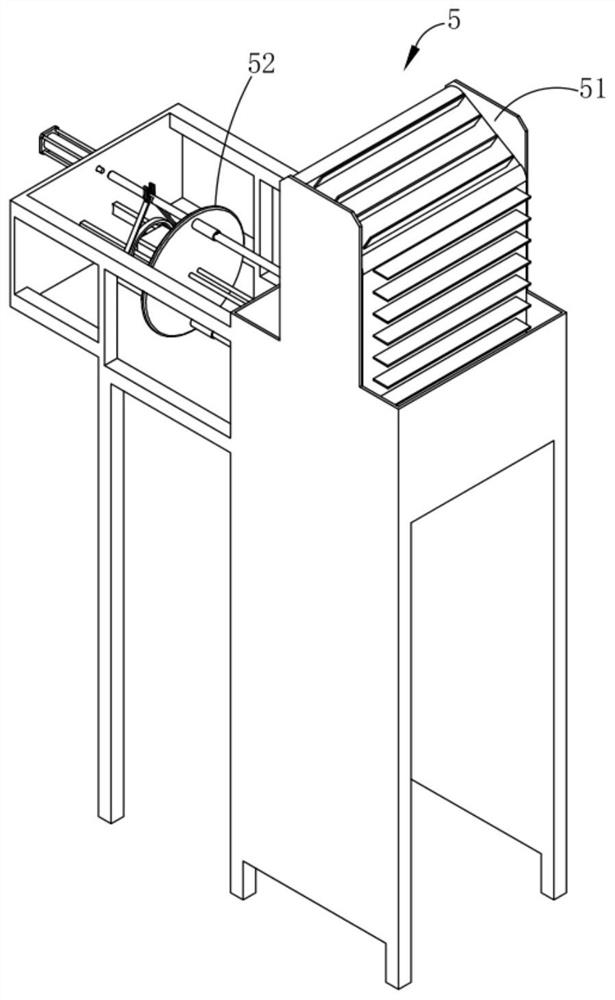

[0043] Such as Figures 1 to 7 As shown, an automatic production line for bubble water toys includes a transmission mechanism 1, a filling mechanism 2, a cap mechanism 3, and a labeling mechanism 4, and also includes a The blowing stick filling mechanism 5 between the cap mechanism 3, the blowing stick filling mechanism 5 includes a feeding component 51, a transfer component 52 and a distance component 53;

[0044] A feeding assembly 51, the feeding assembly 51 is used to place the blowing rod 10 on the transfer assembly 52;

...

Embodiment 2

[0053] Such as Figure 8 , 11 and 12, wherein the same or corresponding parts as in the first embodiment adopt the corresponding reference numerals with the first embodiment, for the sake of simplicity, only the differences from the first embodiment are described below; the second embodiment is different from the first embodiment The difference is that: the distance dividing assembly 53 is arranged in the horizontal direction and is in transmission connection with the driving part 523. The distance dividing assembly 53 includes a fixed guide cylinder 531 and a partition part slidingly arranged in the guide cylinder 531. 532 and the transmission part 533 that connects the partition part 532 and the drive part 523; in this embodiment, the transmission part 533 is provided with a connecting rod structure, that is, the push part 5233 synchronously drives the partition part 532 to move directional during the extension process; The push piece 5233 on the driving part 523 drives the...

Embodiment 3

[0056] According to the manual attached Figure 13 Describe the automatic production method of a kind of bubble water toy in the present embodiment.

[0057] A kind of bubble water toy automatic production method, comprises the following steps:

[0058] (a) for the feeding part, a number of bubble bottles 20 are manually placed on the transmission mechanism 1 one by one, and the linear transmission is driven by it;

[0059] (b) the filling part, after step (a), the bubble bottle 20 is driven by the transmission mechanism 1 to move to the filling station, and the bubble water is injected into the bubble bottle 20 through the filling mechanism 2;

[0060] (c) Bubble blowing stick filling part, after step (b), the bubble bottle 20 is transferred to the filling station through the transmission mechanism 1, and a plurality of blowing sticks 10 are placed in the transfer component one by one through the feeding component 51 After the material receiving part A521 on the 52 is put o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com