Mechanized mining method for gently-inclined medium-thick ore body

A technology with a gentle slope, medium thickness, and mining methods, which is applied in ground mining, underground mining, special mining, etc. It can solve the problems of long production line, low ore recovery rate, ore loss, etc., and achieve a high degree of mechanization and cutting engineering The effect of small amount and high ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0041] The gently inclined medium-thick ore body is produced in a layered or layered shape. The dip angle of the ore body is 5-20°, the thickness is 10-16m, and the length of the ore body along the strike is 755-890m. The stability of the ore rock in this mining area is good. , ore body mining is less affected by groundwater, and the engineering geological conditions are of medium type.

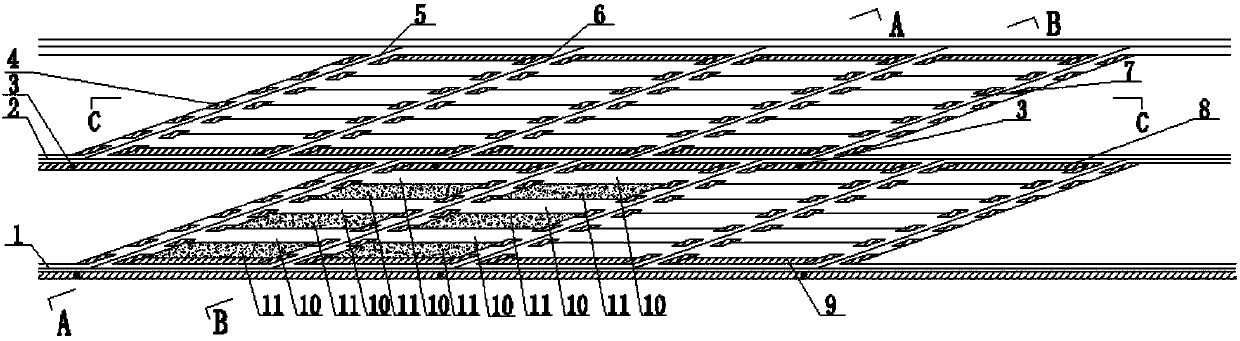

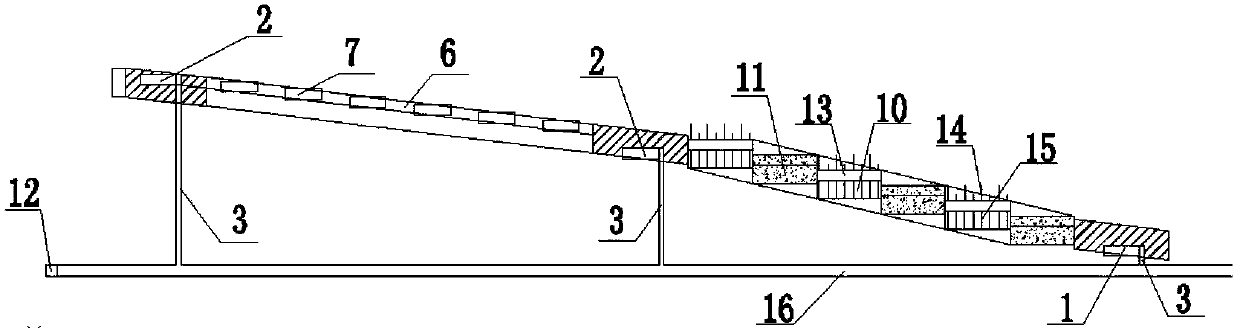

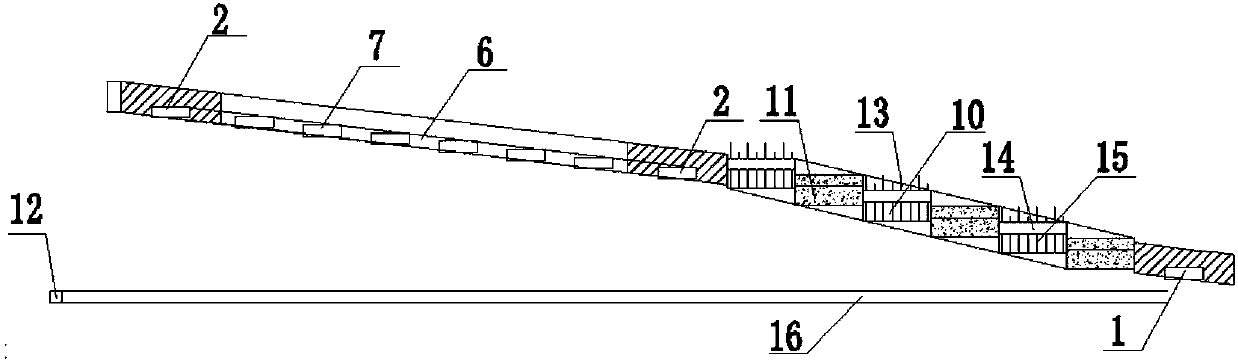

[0042] Acquisition and cutting: such as figure 1 , 2 , 3 and 4, the gently inclined medium-thick ore body is divided into panels, and the ore bodies in the panel are divided into strips along the strike of the ore body, that is, the strips in the panel are divided into one-step stopes 11 and Two-step stope 10, every 12 stopes are used as a panel area, and a panel ore delivery chute 3 is arranged on the bottom side of the panel area. 2 and 12 are connected; excavate pseudo-inclined mining uphill roadway 6 and return wind uphill roadway 5 along the ore body's inclination direction, excavate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com