A kind of pre-grouting reinforcement method for the fault structure zone of the working face

A technology for working faces and structural zones, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., and can solve the problems of high cost of shallow hole chemical grouting reinforcement, short distance of pillar support and top control, and grouting problems. Problems such as short distance to solve passive and hysteresis construction problems, obvious effect of roof control and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The specific operation steps of the pre-grouting reinforcement of the 11123 working face of the Pan No. 2 Mine (directional holes are arranged in parallel with the grooved roadway) are as follows:

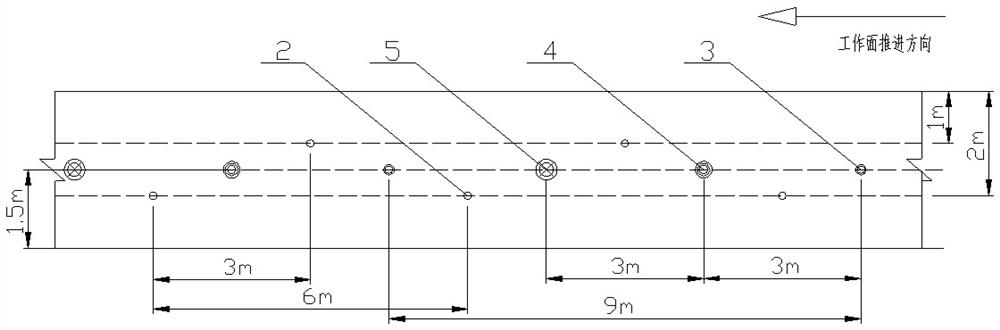

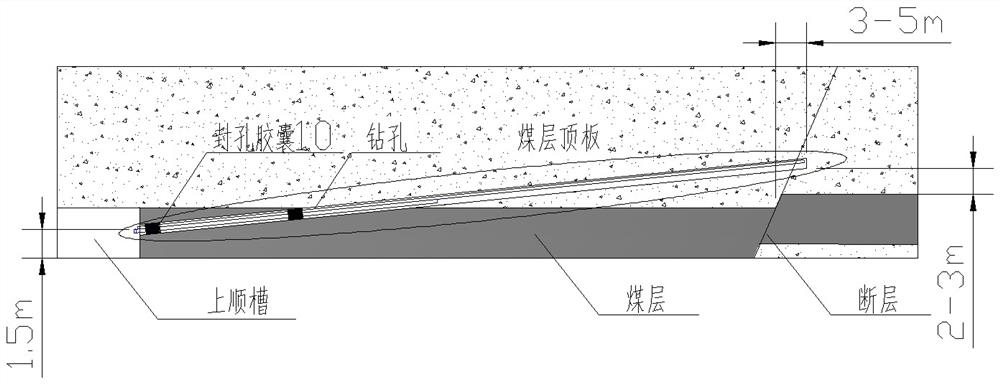

[0041] A four-step progressive grouting scheme combining curtain holes, shallow holes, deep holes and reserved holes is adopted in the upper groove of the 11123 working face; , hole sealing, grouting sequence of shallow hole, deep hole, reserved hole "step-by-step" grouting process.

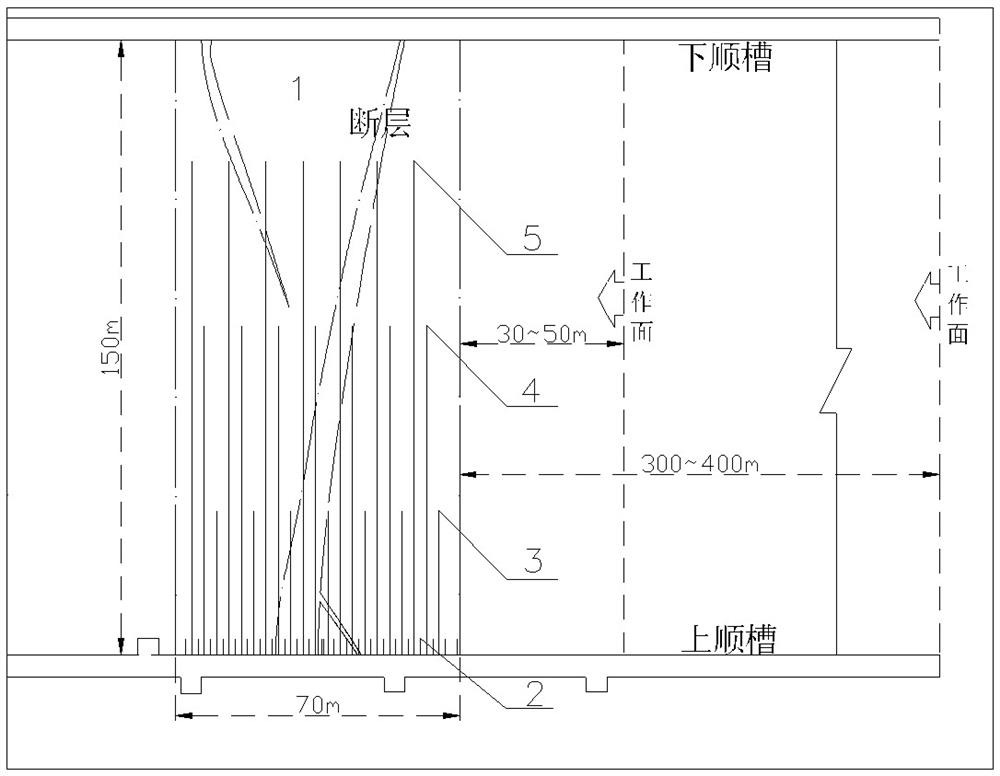

[0042] (1) Curtain grouting

[0043] see figure 1 When the 11123 working face is 300~400m away from the edge of the fault structural belt 1, the upper part of the working face along the upper groove of the fault structural belt 1 within the range of 150 m in length and 70 m in width shall be constructed from right to left in the same direction as the advancing direction of the working face. Curtain grouting holes 2 in parallel rows are arranged in a staggered and crossed arrangement. Each hol...

Embodiment 2

[0051] The specific operation steps of Zhangji Mine 1613 (3) working face fault structural belt pre-grouting reinforcement (directional hole drilling field fan-shaped centralized arrangement) are as follows:

[0052] see Figure 5 , in the drilling field 6, by adjusting the angle and length of the drilling holes one by one to complete the centralized arrangement of fan-shaped directional holes, and complete the drilling of curtain holes, shallow holes, deep holes, reserved holes, pipe down, sealing and step-by-step progress. grouting.

[0053] (1) Curtain grouting

[0054] see Figure 5 , in the upper and lower drilling field 6 and the surrounding area of 35-50m within the fault structure belt 1 (length 240m, width 150m), two rows of horizontal curtain grouting holes 2 are constructed in sequence, and they are arranged in a dislocation and cross. Each hole in the first row corresponds to the middle part between two adjacent holes in the first row. The horizontal distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com