Acidic slag-based filling material and preparation method thereof

A technology of filling materials and slag, which is applied in the direction of filling materials, mining equipment, earth square drilling, etc., can solve the problems of low utilization rate and volume stability, and achieve the effects of low cost, good fluidity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

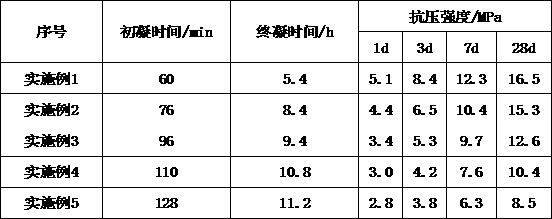

Examples

preparation example Construction

[0050] The invention discloses a method for preparing an acidic slag-based filling material, which comprises the following steps:

[0051] (1) Prepare 50-150 parts of acidic slag, 30-40 parts of high alkalinity powder, 10-20 parts of ultra-fine active powder, 1-5 parts of acid-base regulator, and 1-5 parts of dispersed adsorbent according to the number of parts by mass 2-10 parts of swelling components, 0.5-1.5 parts of thickening water-retaining agent, and 0.5-1.5 parts of retarding superplasticizer.

[0052] (2) Mix the raw materials prepared in step 1 with water at a ratio of 1:0.8-1.1 to obtain the slag-based filling material.

[0053] The invention discloses an acidic slag-based filling material and the application of the preparation method thereof in the field of mine filling.

Embodiment 1

[0055] A slag-based filling material, preparation method and application, comprising the following steps:

[0056] (1) Prepare 50-150 parts of acidic slag and 30-40 parts of high alkalinity powder according to the mass parts (component ratio: 30-40 parts of high-calcium fly ash, 30-40 parts of brucite powder, silicon micropowder 30-40 parts), ultra-fine active powder 10-20 parts (component ratio: 30-40 parts of nano-calcium sulfoaluminate, 30-40 parts of nano-porous calcium phosphate, 30-40 parts of nano-light burned magnesium), 1-5 parts of acid-base regulator (component ratio: 30-40 parts of sodium aluminate, 30-40 parts of sodium tripolyphosphate, 30-40 parts of anhydrous sodium tetraborate), 1-5 parts of dispersed adsorbent ( The component distribution ratio is: 40-60 parts of sodium-based bentonite, 40-60 parts of calcium-based bentonite), 2-10 parts of quicklime, 0.5-1.5 parts of hydroxyethyl cellulose ether, 0.5-1.5 parts of retarding superplasticizer (group The distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com