A physicochemical combined roofing method for stope filling

A technology of roofing rate and filling body, which is applied in the fields of fillings, mining equipment, earth-moving drilling, etc., can solve the problems that the surface needs to be protected inapplicable, the target filling and roofing effect cannot be achieved, and the financial and material resources are wasted. Achieve the effect of preventing surface collapse, shortening filling cycle and reducing filling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

[0053] The invention provides a physical-chemical combined roofing method for stope filling.

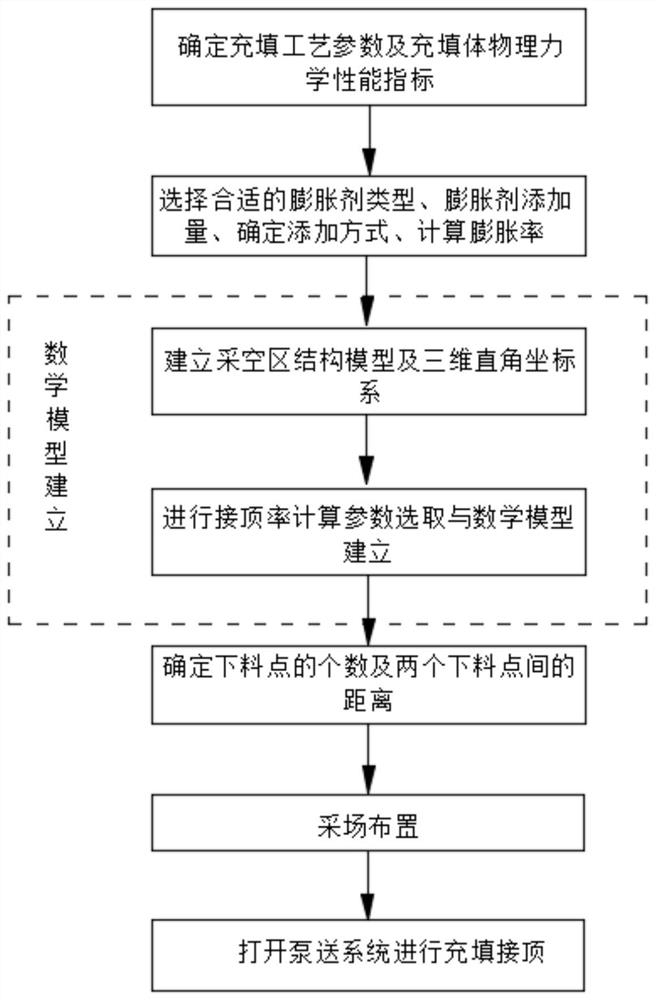

[0054] like figure 1 As shown, the method includes the following steps:

[0055]S1: According to the actual production situation of the mine, determine the filling process parameters and the physical and mechanical performance indicators of the filling body;

[0056] S2: According to the needs of the mine, select the appropriate type of expansion agent, the amount of expansion agent added, determine the addition method of the expansion agent, and calculate the expansion ratio;

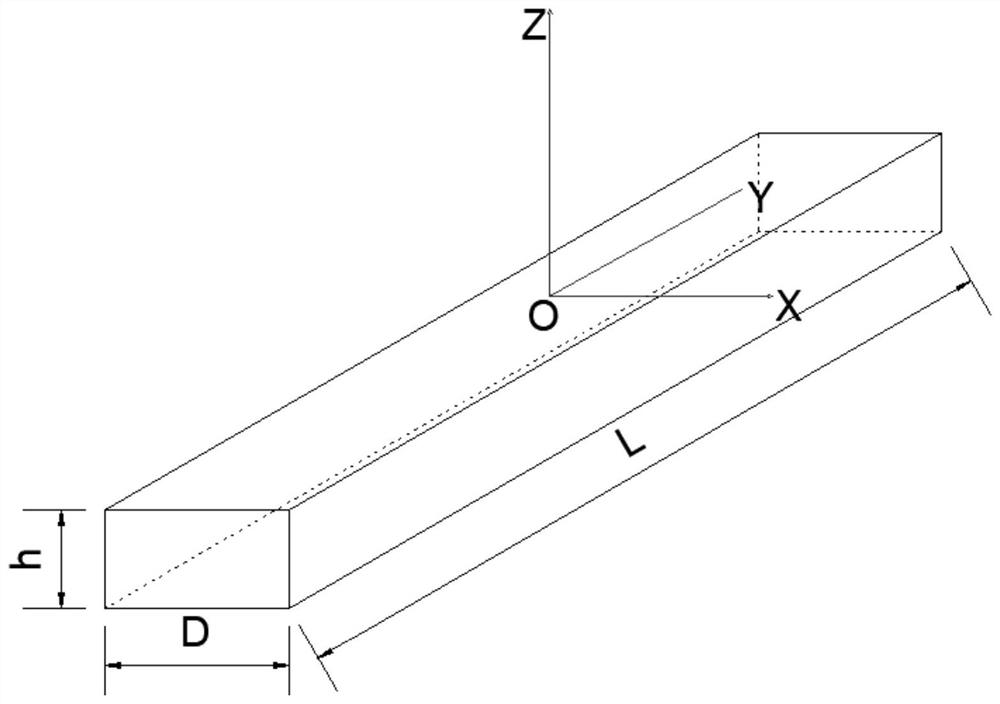

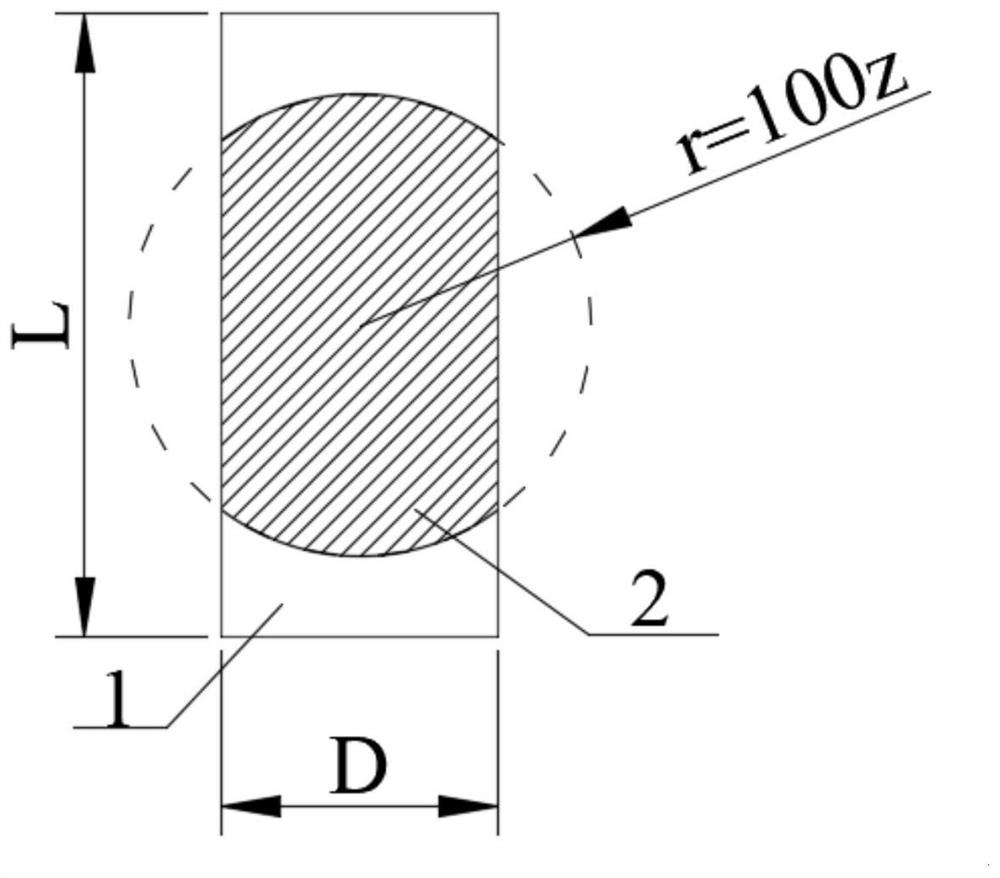

[0057] S3: According to the structure parameters of the gob, establish the structure model of the gob and the three-dimensional Cartesian coordinate system;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com